A motion trajectory control method of laser peening robot for exhaust casing

A robot movement and trajectory control technology, applied in the field of surface treatment of parts, can solve the problems of low lapping precision of curved surface spots, structural shading, and casing collision with light outlets, etc., to improve the efficiency of process research and development, improve uniformity, and good operability The effect of sex and control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] A motion trajectory control method of a laser shot peening robot facing an exhaust casing, comprising the following steps:

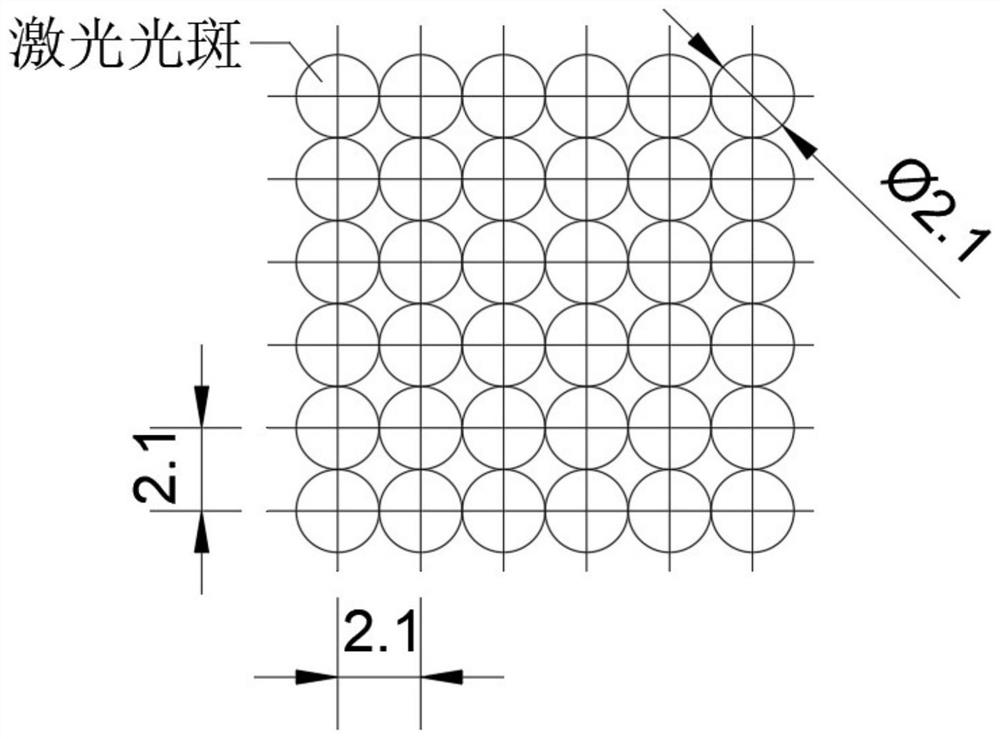

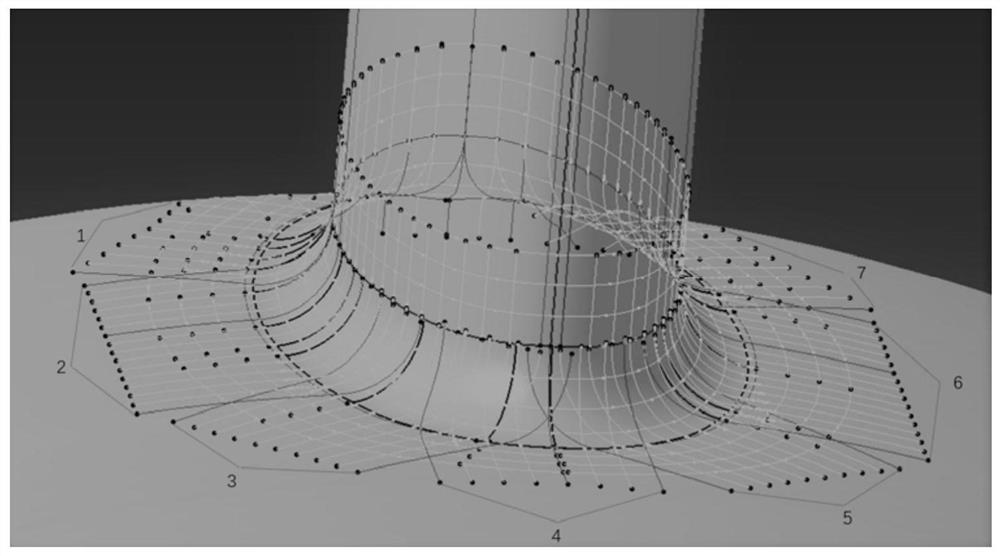

[0048] 1) Obtain the 3D model of the exhaust casing and use UG software to read it; determine the area to be strengthened as the transition fillet between the exhaust casing support plate and the outer flow channel; divide the surface of the area to be strengthened to obtain the coordinates of the exhaust casing The coordinates of the grid points in the system; the diameter of the laser spot is Φ2.1mm, such as figure 1 As shown, the grid is divided by equidistant curves with a spacing of 2.1mm, and multiple sets of equidistant curves are used to cover the area to be strengthened. The grid point after gridding is the center of the laser spot, such as figure 2 shown.

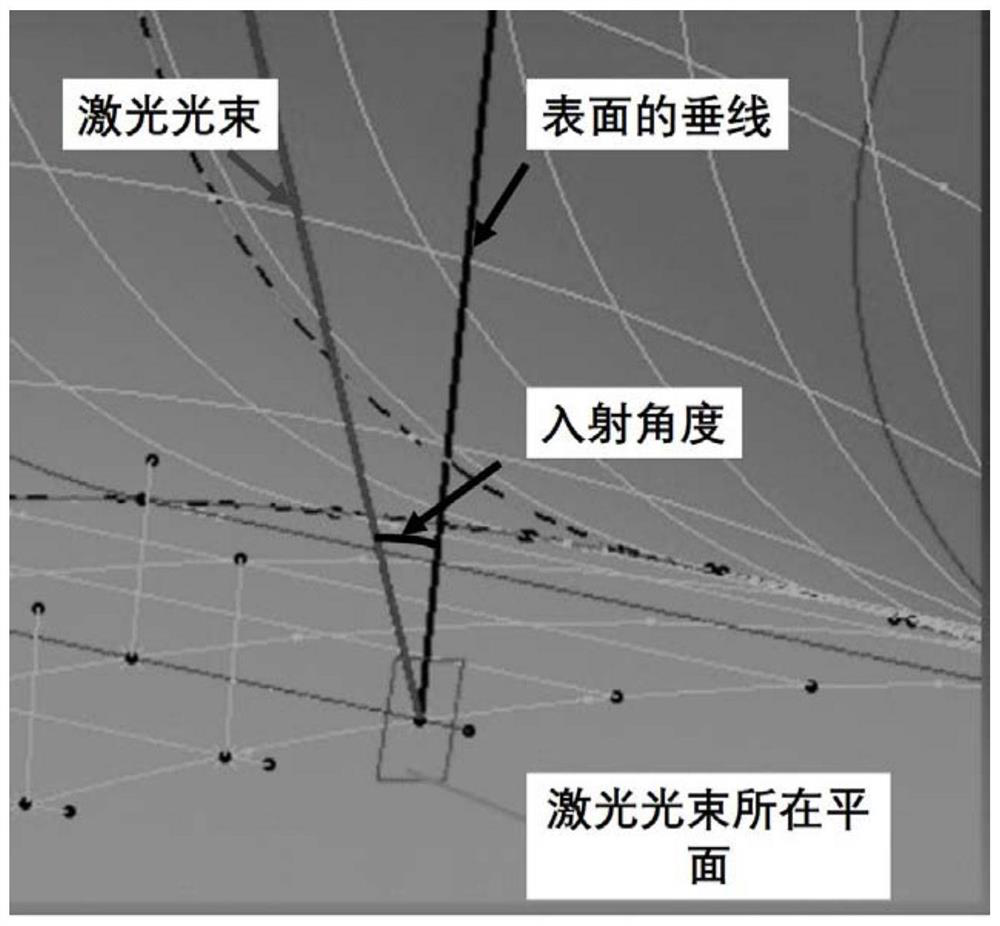

[0049] 2) Analyze the shading of the area to be strengthened in other areas of the exhaust casing, determine the laser incident angle of each grid point; determine the coordinates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com