Consideration of hand torque deviation in vehicle steering system

A steering system and vehicle technology, applied in the field of vehicle steering systems, can solve problems such as the inability to utilize the steering function and the inability of the vehicle to always achieve steering feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

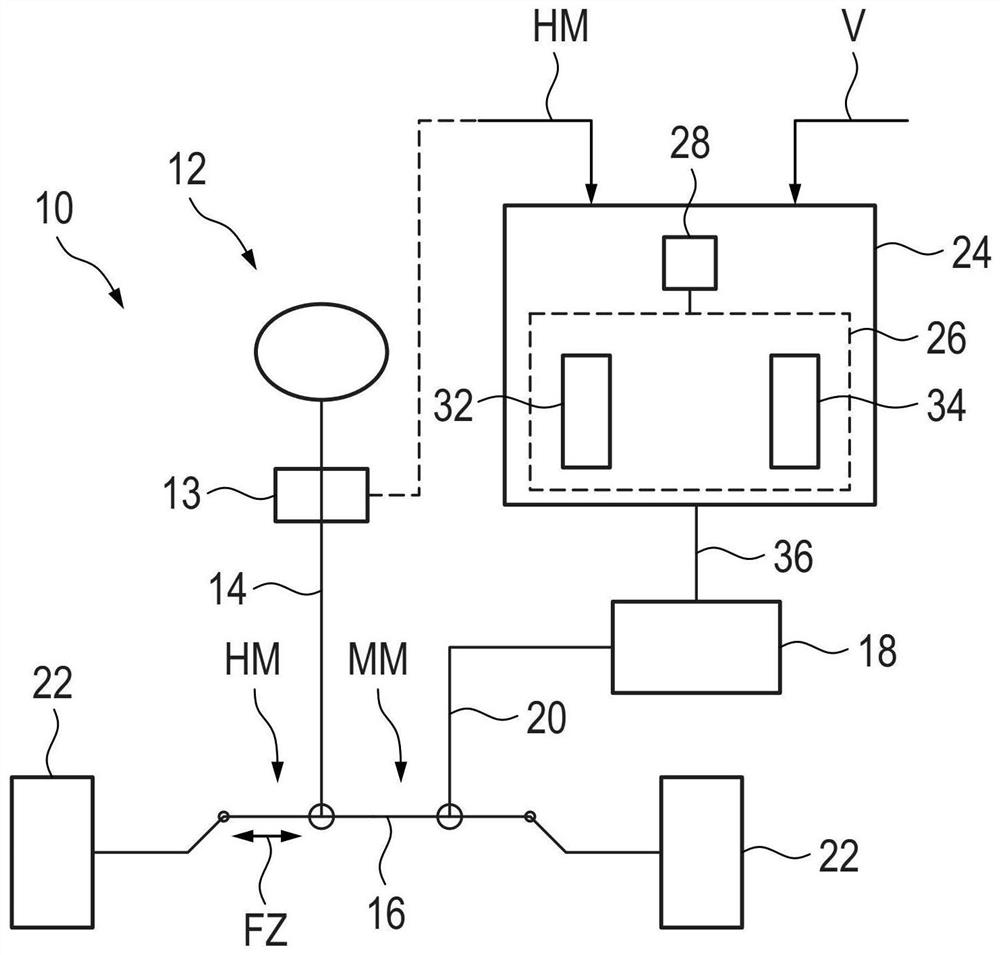

[0067] exist figure 1 A vehicle steering system 10 , which is included in a vehicle 1 which is not otherwise specifically shown, is shown schematically. The vehicle steering system includes a steering control 12 in the form of a steering wheel. The steering wheel is coupled to a rack 16 via a steering rod 14 (which constitutes the shaft), so that rotation of the steering control 12 can be converted into a linear movement of the rack 16 (in figure 1 from left to right). The torque exerted by the driver on the rack 16 via the steering control element 12 and the steering rod 14 is referred to as the manual torque HM.

[0068] An electric motor (servomotor) 18 also acts on the toothed rack 16 via a mechanical coupling 20 shown very schematically. The rotation of the output shaft of the servo motor 18 is converted into a linear movement of the toothed rack 16 by means of a coupling device 20 . The torque generated by the electric motor 18 and acting on the toothed rack 16 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com