An anti-pollution beverage packaging bag

A packaging bag and anti-pollution technology, applied in the field of packaging bags, can solve problems such as difficult moisture-proof effect, pollution, and difficulty in controlling usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

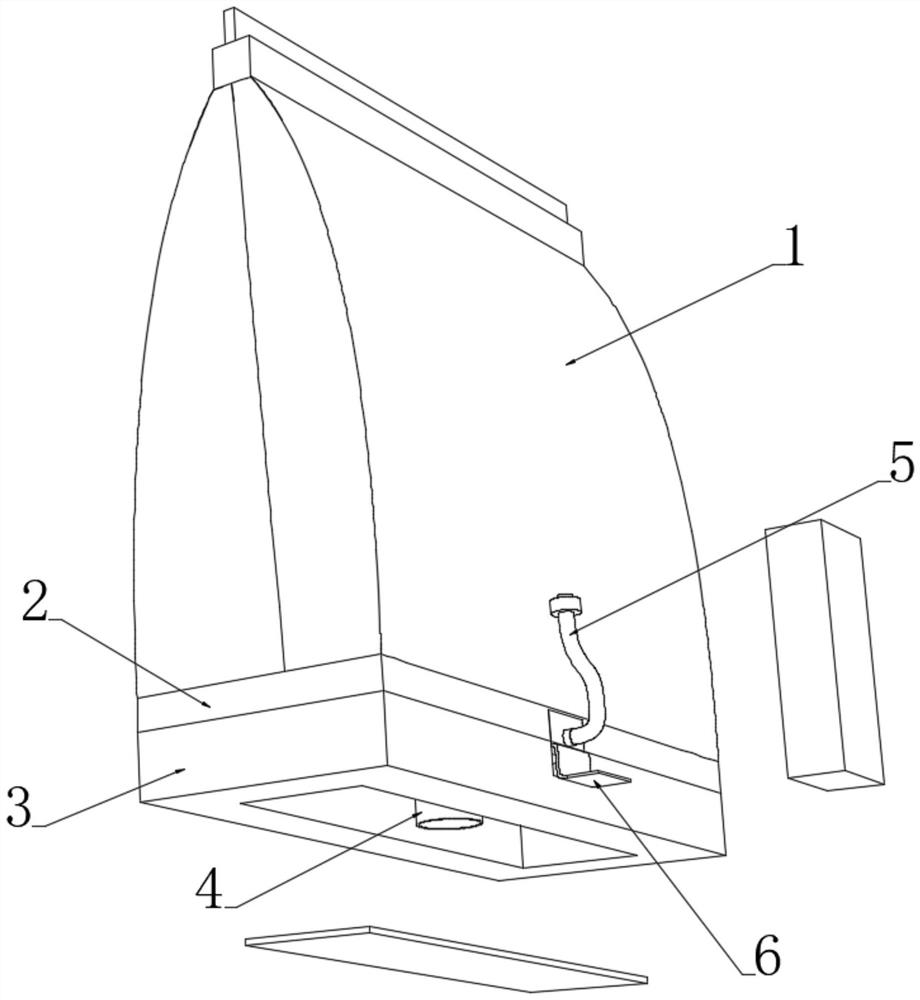

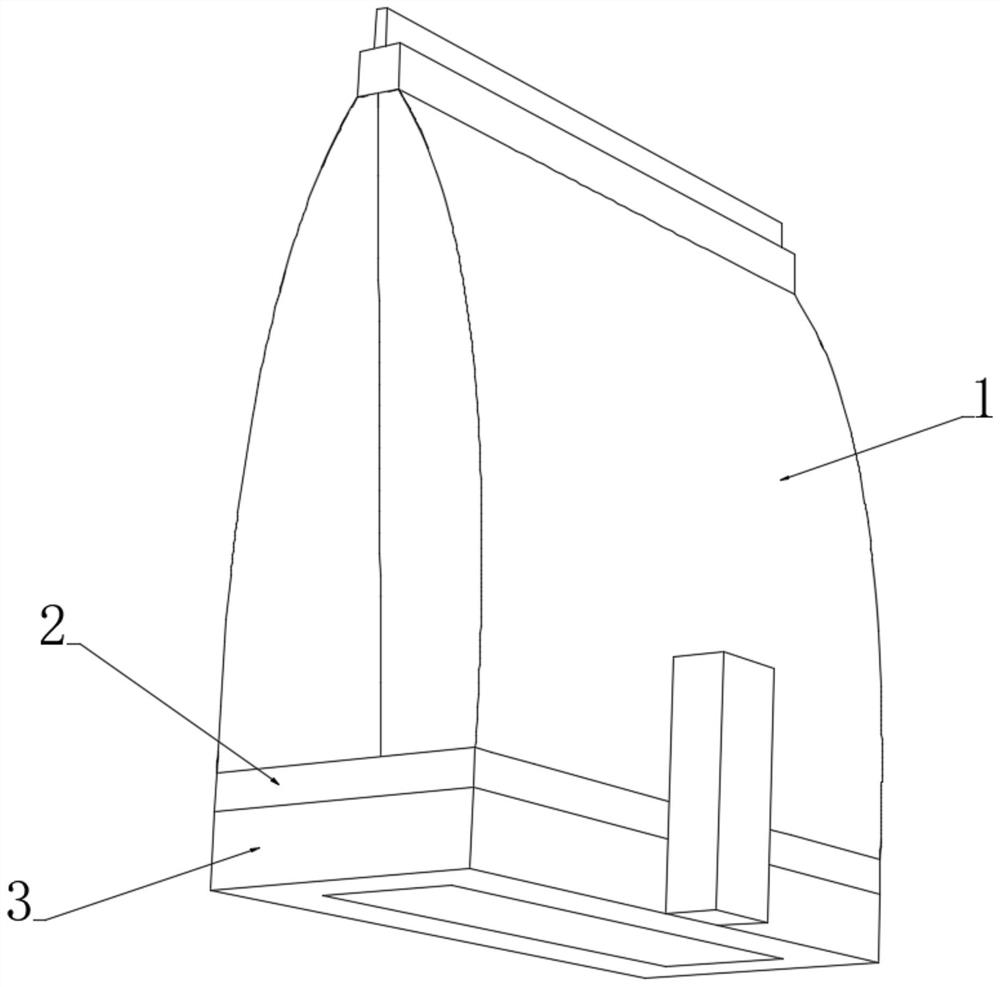

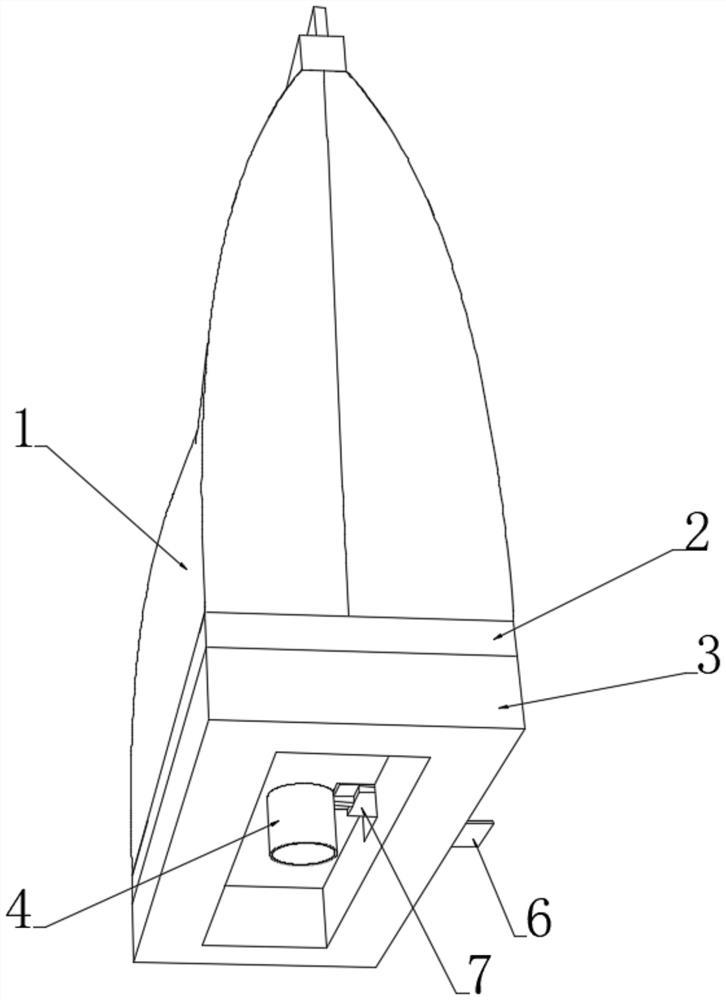

[0044] see Figure 1-3 and Figure 5-6 , an anti-pollution beverage packaging bag, comprising a bag body 1, the bottom end of the bag body 1 is sequentially provided with a base 2 and a reclaiming seat 3, the reclaiming seat 3 is provided with a reclaiming cylinder 4, and the reclaiming seat 3 is provided with a In the cavity where the material cylinder 4 is installed, the upper end of the reclaiming cylinder 4 extends to the inside of the bag body 1, the top of the reclaiming cylinder 4 is provided with a suction pipe 8, and the lower end wall of the suction pipe 8 is provided with a suction port 801. There is a dividing plate 12 inside, and the dividing plate 12 divides the inside of the reclaiming cylinder 4 into an upper reclaiming cavity and a lower hollow cavity, and a material guide pipe 5 is embedded on the outer side wall of the base 2, and the inner end of the material guide pipe 5 penetrates through the base. 2 and communicate with the upper reclaiming cavity, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com