Turning belt conveyor with chain wheel convenient to replace

A belt conveyor, convenient replacement technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of installation space installation, inconvenient disassembly, etc., to achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

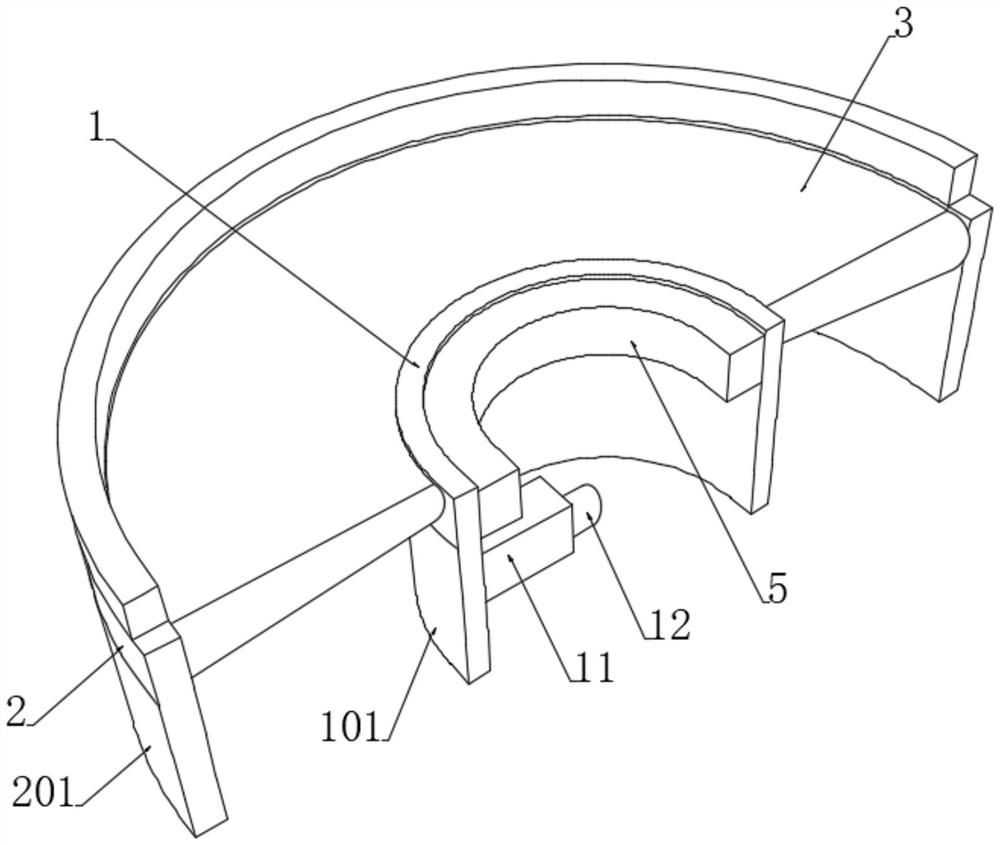

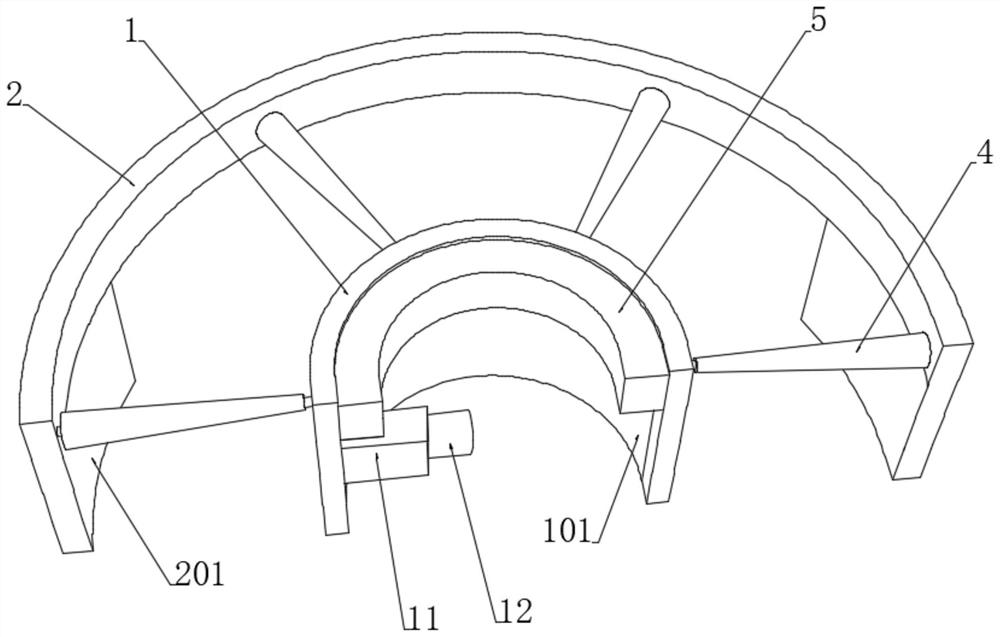

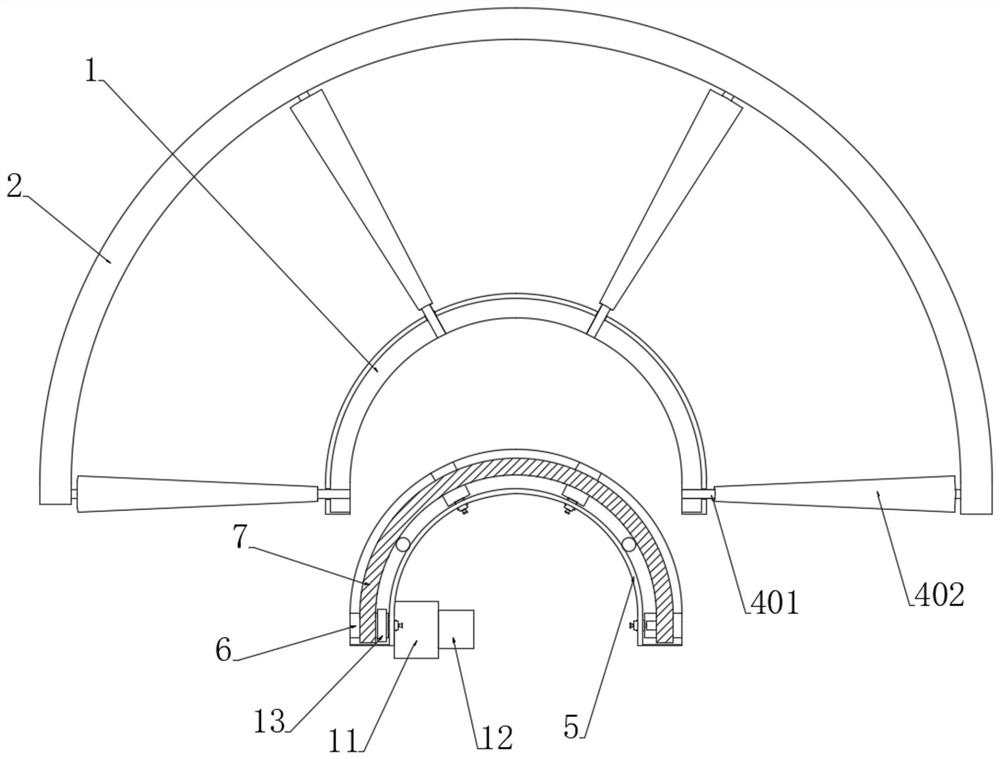

[0042] see Figure 1-3 , a curved belt conveyor that facilitates the replacement of sprockets, including an inner arc frame 1 and an outer arc frame 2 distributed inside and outside, and the bottom ends of the inner arc frame 1 and the outer arc frame 2 are equipped with an inner bearing seat 101 , the outer bearing seat 201, a plurality of tapered rollers 4 are annularly distributed between the inner arc-shaped frame 1 and the outer arc-shaped frame 2, and the transmission belt 3 is connected to the plurality of tapered rollers 4, and the inner arc-shaped frame 1 and the outer arc-shaped frame 2 are both arc-shaped structures to realize the turning transmission of materials. The inner bearing seat 101 and the outer bearing seat 201 play a bottom support role for the inner arc-shaped frame 1 and the outer arc-shaped frame 2 respectively. The rotating shaft 401 between the shaped frame 1 and the outer arc frame 2, the rotating shaft 401 is fixedly sleeved with a conical roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com