Built-in magnetic buckle type building curtain wall

A magnetic buckle and built-in technology, applied in construction, building components, building structures, etc., can solve problems such as cumbersome operation, inconvenient disassembly, and difficult mechanical installation of fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

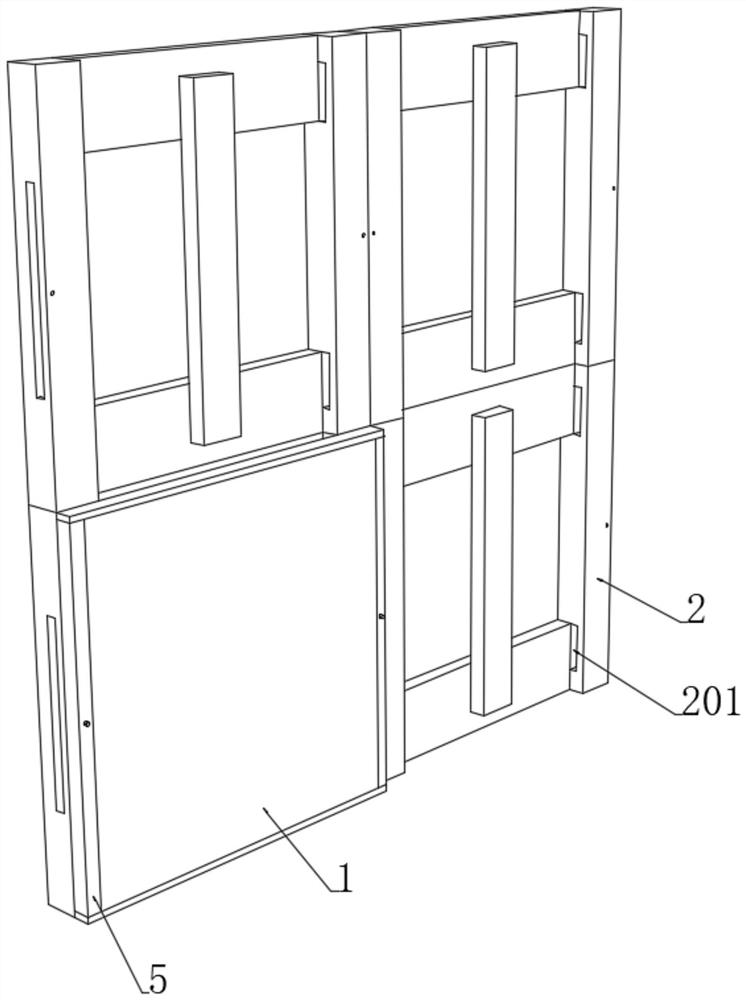

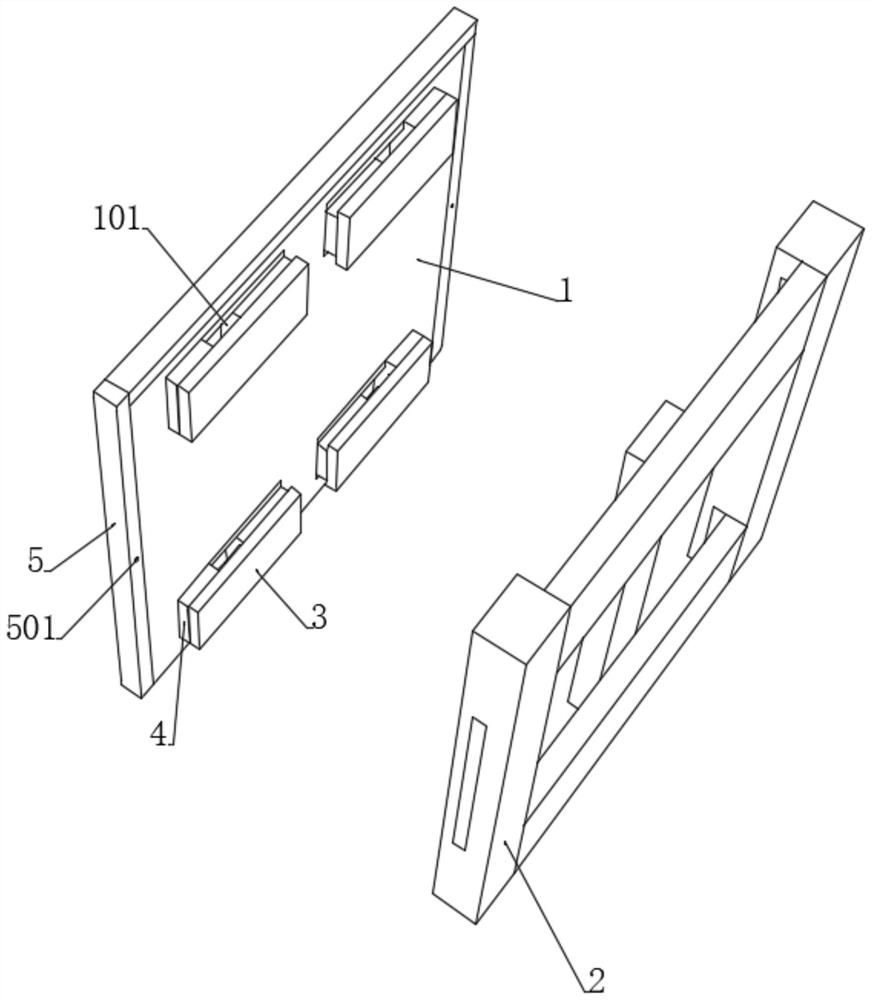

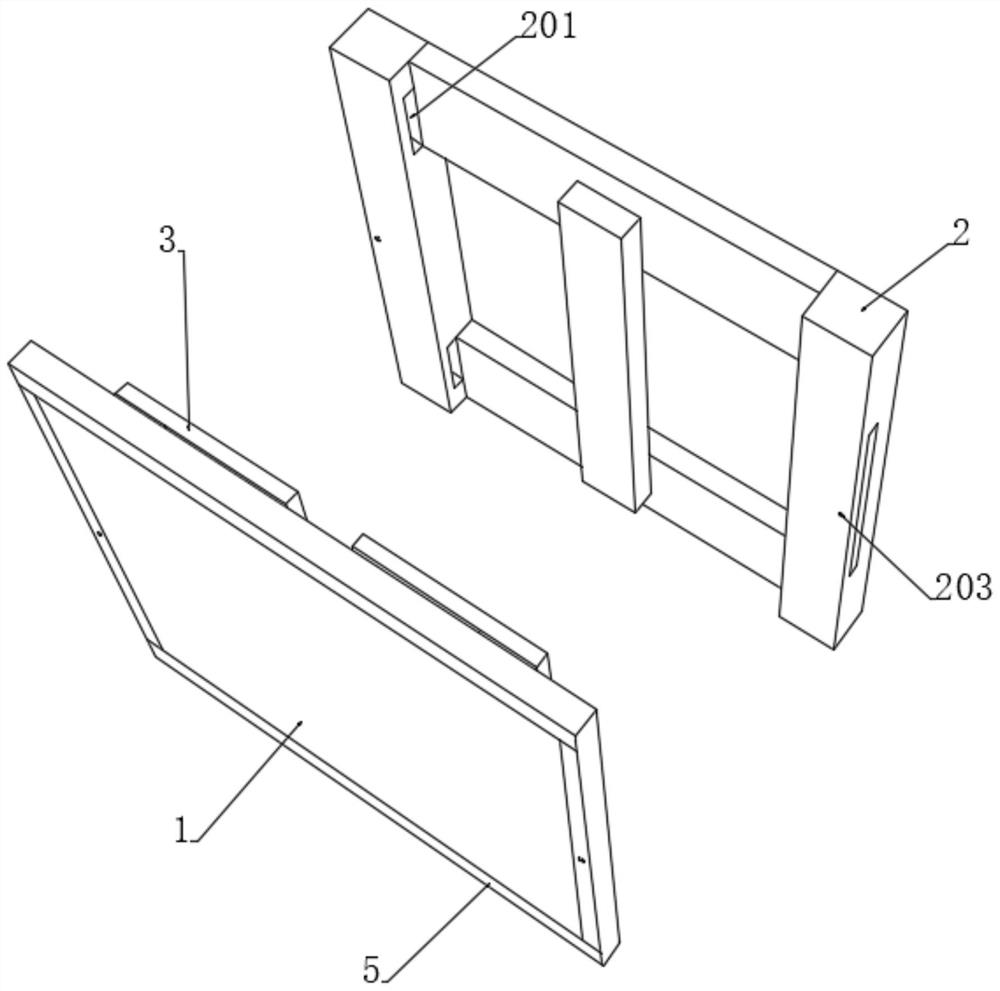

[0042] see Figure 1-3 , a built-in magnetic buckle type building curtain wall, comprising a glass surface layer 1 and a suspension body frame fixedly installed on the wall body, the outer end wall of the glass surface layer 1 is covered with an elastic exterior decoration capsule 5, and the suspension body frame includes The bone brace and the built-in connecting columns 2 located on both sides of the bone brace, the upper and lower sides of the glass surface layer 1 are slidingly connected with an L-shaped magnetic buckle setting plate 3, and the bone brace includes two connecting columns connected between a pair of built-in connecting columns 2. Two beams are connected with uprights. The uprights are located between two pairs of L-shaped magnetic fastening plates 3 that are left and right symmetrical. When installing, the uprights are embedded between the two pairs of L-shaped magnetic buckle plates 3. In between, it is easy to quickly locate the glass surface layer 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com