Anti-pollution beverage packaging bag

A packaging bag and anti-pollution technology, applied in the field of packaging bags, can solve problems such as pollution, inconvenient operation, and difficult moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

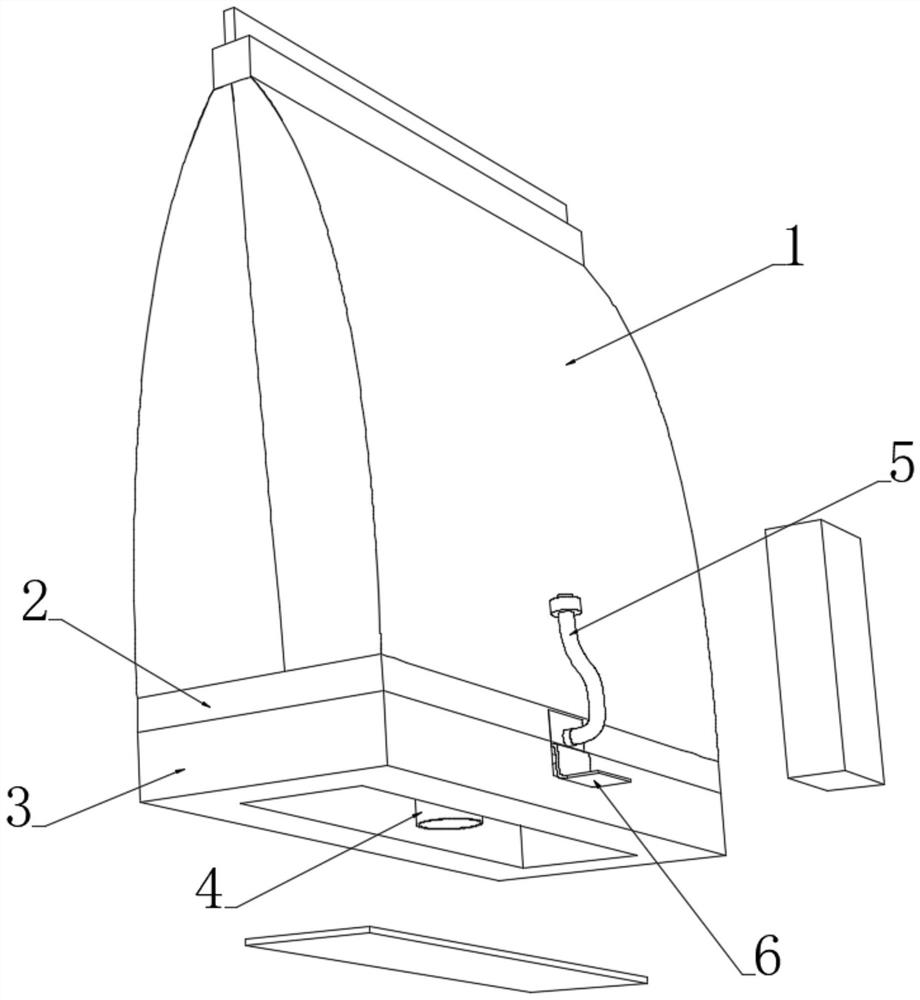

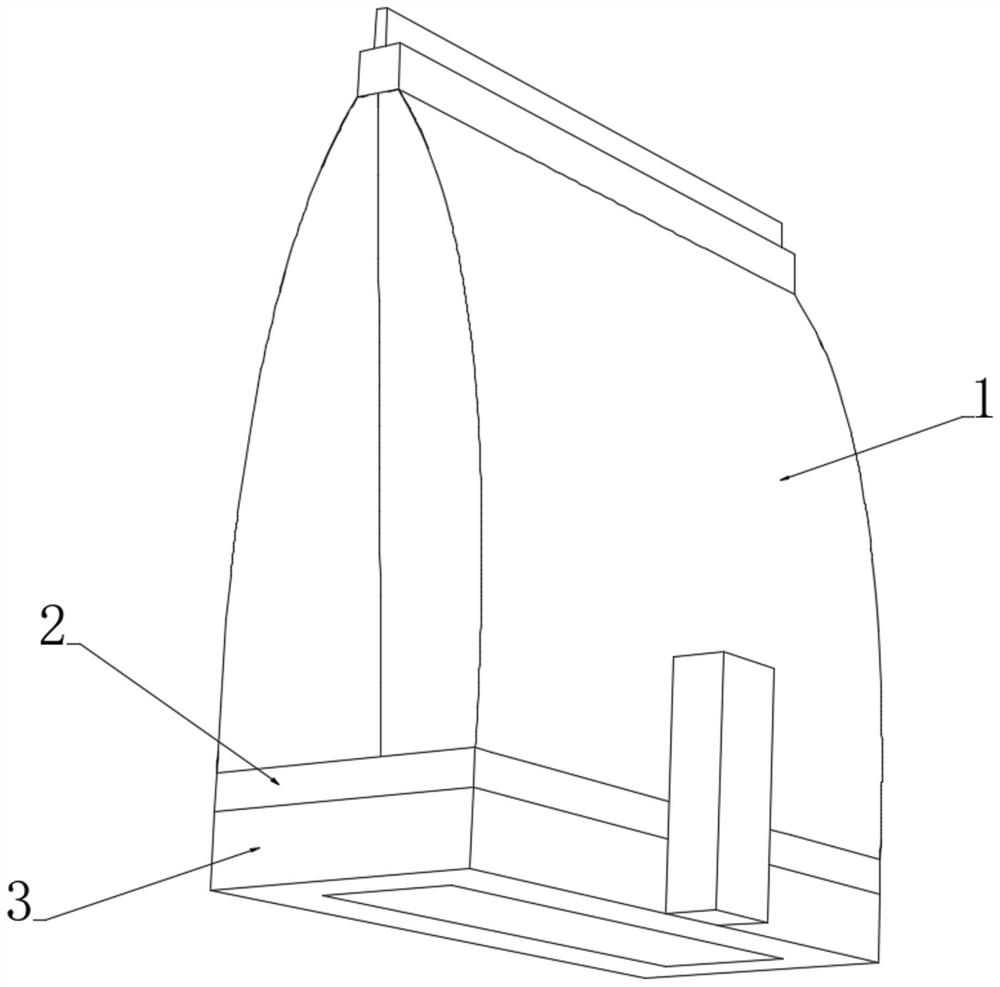

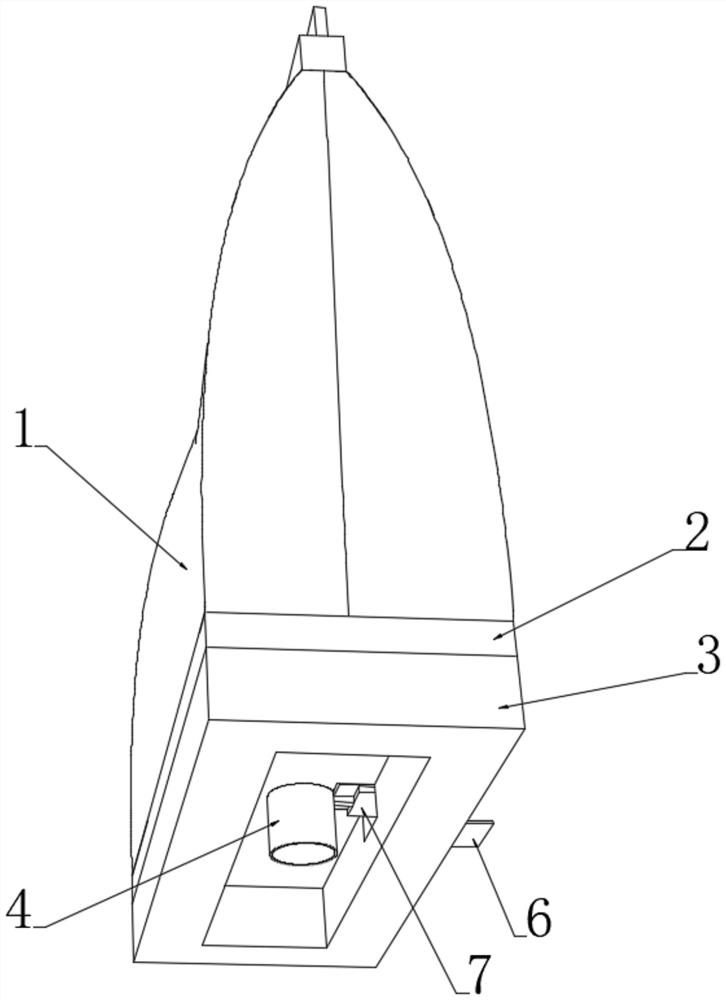

[0044] see Figure 1-3 and Figure 5-6 , an anti-pollution drink packaging bag, comprising a bag body 1, the bottom of the bag body 1 is provided with a base 2 and a retrieving seat 3 in turn, the retrieving seat 3 is provided with a retrieving barrel 4, and the retrieving seat 3 is provided with a The cavity of the barrel 4 is installed, the upper end of the barrel 4 extends to the inside of the bag body 1, the top of the barrel 4 is provided with a suction pipe 8, the lower end wall of the suction pipe 8 is provided with a suction port 801, and the barrel 4 is A partition plate 12 is provided inside, and the partition plate 12 divides the interior of the material-taking cylinder 4 into an upper material-feeding cavity and a lower hollow cavity, and a material guide tube 5 is embedded on the outer wall of the base 2, and the inner end of the material guide tube 5 runs through the base 2 and connected with the upper material extraction chamber, the material guide pipe 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com