Method for setting operating force range of engineering machinery and evaluating operation fatigue of driver

A technology for construction machinery and setting methods, which is applied in diagnostic recording/measurement, medical science, sensors, etc., to make up for untruth and inaccuracy, solve quantitative evaluation problems, and make experimental results more authentic and credible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

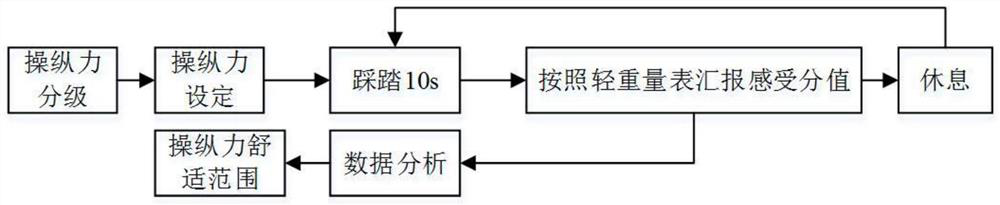

[0038] A method for setting the operating force range of construction machinery components, in which a subject manipulates the components under the set operating force, including: collecting the subject's subjective fatigue data according to the set time interval; collecting the subject's fatigue data; The myoelectric signal of muscle feedback; data processing is performed on the collected myoelectric signal to obtain the degree of muscle activation of the subject under the set operating force; based on the subjective fatigue data and muscle activation degree values of all subjects, determine the operating force range.

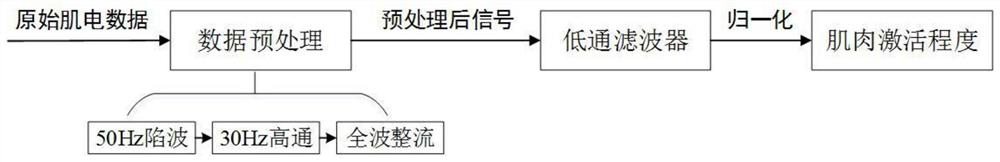

[0039] The data preprocessing of the collected electromyographic signals to obtain the degree of muscle activation of the subject under the set operating force includes: performing data preprocessing on the collected electromyographic signals; The low-pass filter performs data filtering and obtains the root mean square value of the electromyographic signal; ...

Embodiment 2

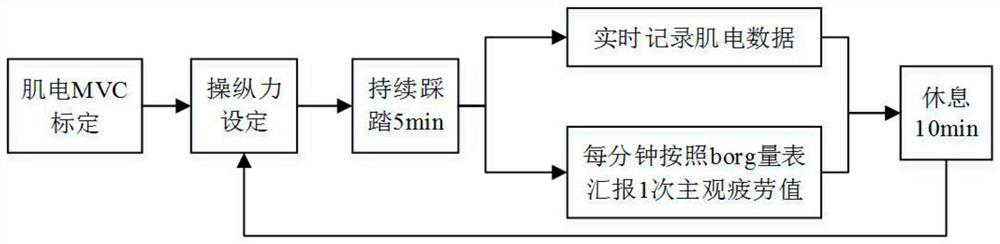

[0070] Such as Figure 4 , Figure 5 As shown, based on the setting method of the operating force range of construction machinery components shown in Embodiment 1, this embodiment provides a method for evaluating the driver’s fatigue degree, select typical products and make a new prototype, that is, change the main operating components in the cab The set value of the operating force, adopt the method similar to the laboratory experiment in the embodiment one to carry out the original vehicle and the prototype test, collect the subjective evaluation data and the myoelectric data; Include: Based on the operating force of the engineering machinery parts described in the embodiment one The range setting method determines the operating force range of the component; based on the determined operating force range, sets the operating force of the component; collects the subject’s subjective fatigue when manipulating the component under the set operating force according to the set time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com