Full-automatic tray cleaning device

A cleaning device and fully automatic technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as affecting production work, single structure, time-consuming and laborious, etc., to ensure production work and good cleaning effect. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

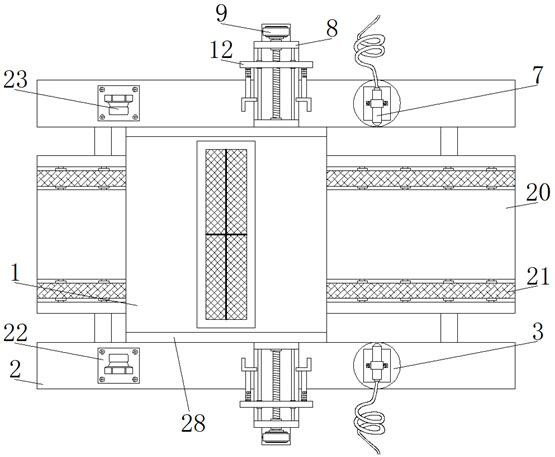

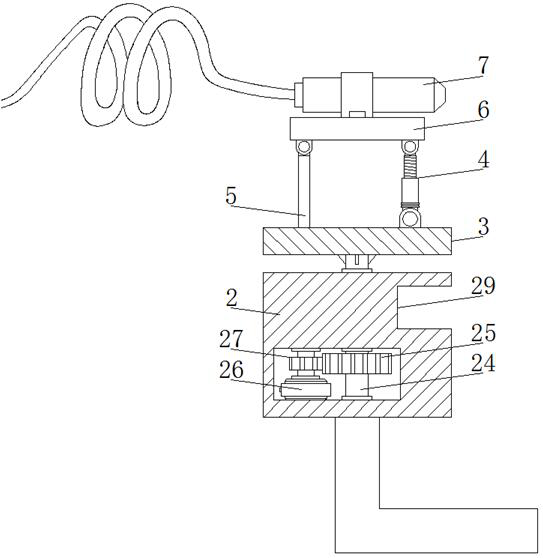

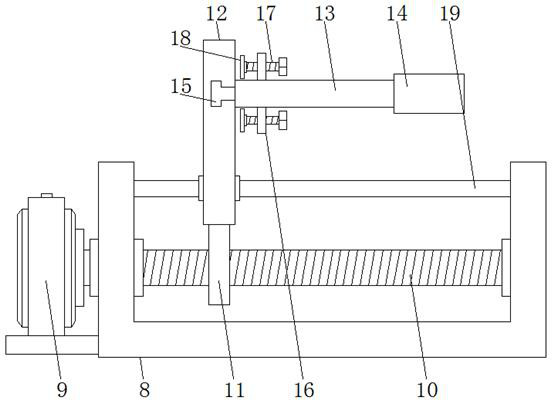

[0020] according to figure 1 , 2 As shown in . Both sides of the transmission assembly are connected with a mounting plate 2, the top of the mounting plate 2 is rotatably connected with a disc 3, and the top of the disc 3 is hinged with a telescopic mechanism 4 on the side close to the transmission plate 1, and the disc 3 A hinged rod 5 is fixed on the side away from the transmission plate 1 at the top, an adjusting plate 6 is arranged above the disc 3, and the telescoping mechanism 4 and the top of the hinged rod 5 are hinged to the bottom end of the adjusting plate 6, and the adjusting plate 6 The top is equipped with an air blowing nozzle 7, and by adjusting the length of the telescopic mechanism 4, the adjustment plate 6 can be adjusted around the top of the hinge rod 5 to adjust the angle of inclination, so as to facilitate the adjustment of the spraying angle of the spraying nozzle 7 according to the cleaning needs, thereby making the cleaning effect better , the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com