Ultralow-height heavy lifting RGV system

A lifting system and heavy-duty technology, applied in the field of RGV, can solve the problems of poor RGV stability, manpower required, cumbersome operation, etc., and achieve the effect of realizing automatic function, reducing stuck situation, and shortening the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

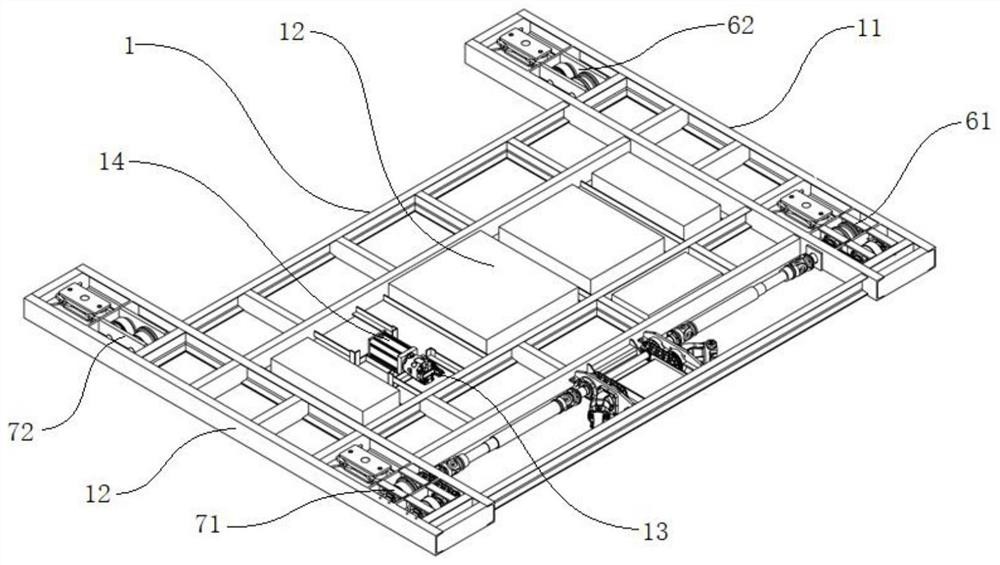

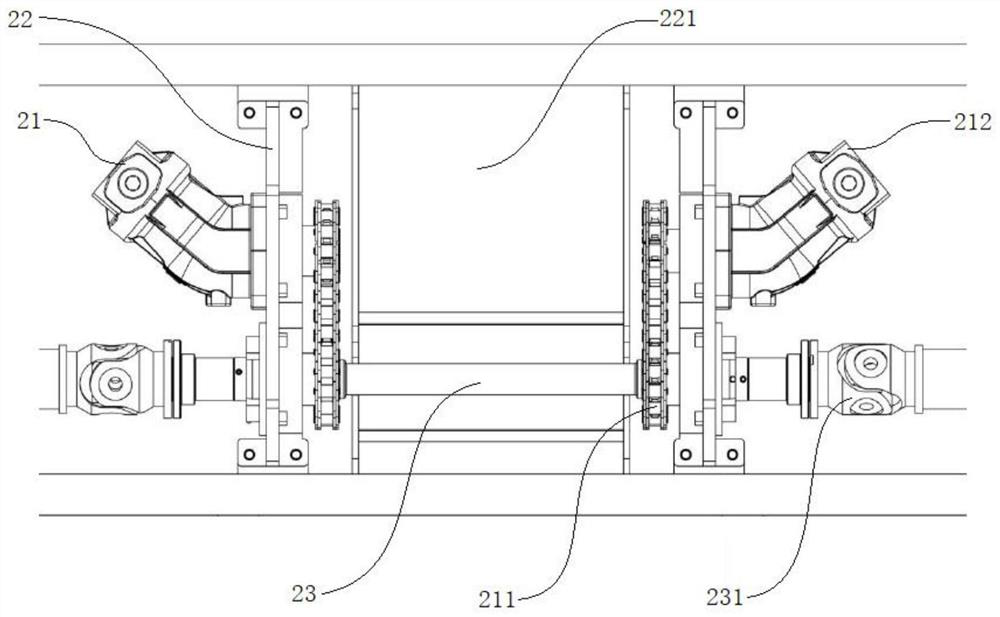

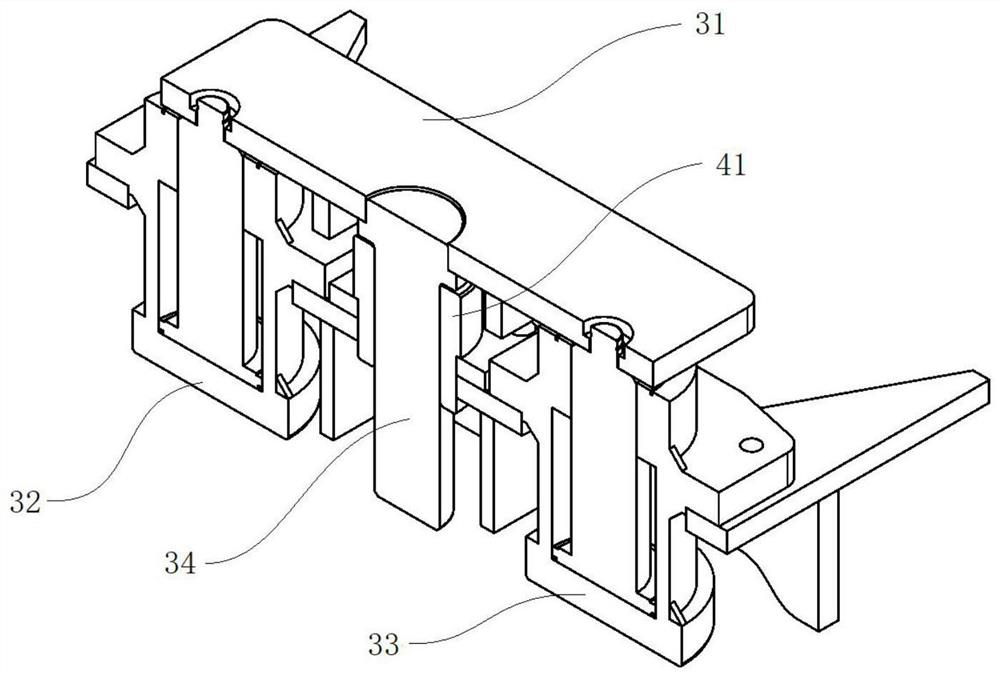

[0028] as attached Figure 1-8 : a kind of ultra-low height heavy-duty lifting RGV system, including chassis 1, traveling system, power system and lifting system; described chassis 1 both sides are provided with traveling frame 11, and described traveling system and lifting system are located at traveling frame 11, so The power system is drivingly connected to the traveling system, the driving pump of the chassis 1 is drivingly connected to the lifting system, and the power system includes a hydraulic motor 21, a mounting frame 22 and a transmission shaft 23; the mounting frame 22 is arranged on the chassis 1, and the The hydraulic motor 21 is installed on the mounting frame 22, the transmission shaft 23 is inserted through the mounting frame 22, the hydraulic motor 21 is driven and connected to the transmission shaft 23 through a chain 211, and the two ends of the tra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap