Vortex groove measuring platform and its measuring unit

A measuring unit and scroll technology, applied in the field of measurement, can solve the problems of difficult measurement of workpieces, high investment costs, etc., and achieve the effect of high flexibility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

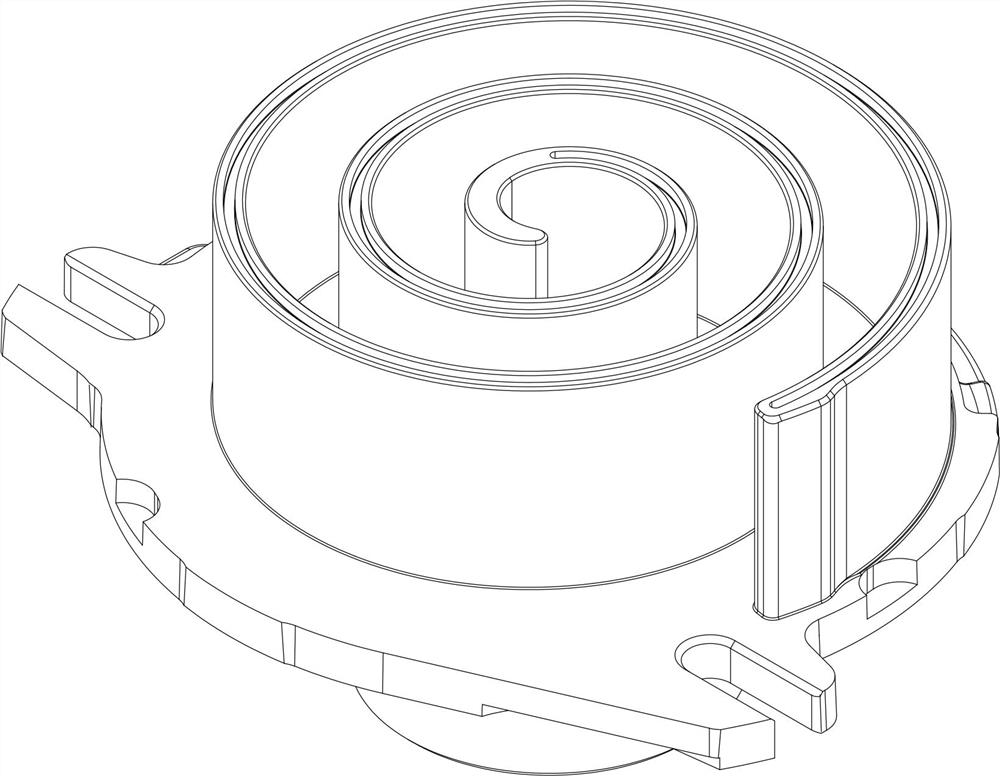

[0025] Workpieces with scroll grooves (e.g. figure 1 According to different models, the size of the workpiece and the structural distribution of the scroll grooves are different. Therefore, in order to adapt to product update iterations, in the environment of automatic measurement, the measuring device is required to meet the measurement of workpieces of various models and sizes. need. In view of this, the present application provides a vortex groove measuring platform with high flexibility and applicability and a measuring unit thereof.

[0026] The technical solutions of the present application will be described in detail below with reference to the accompanying drawings and in combination with implementation manners.

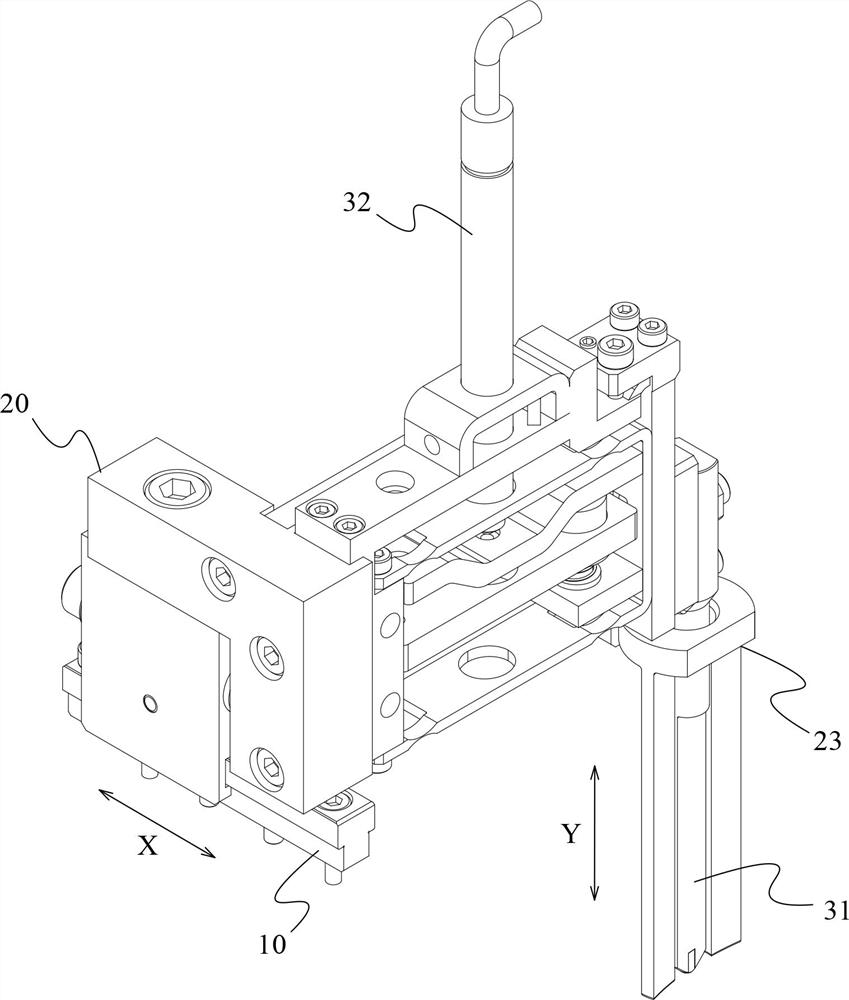

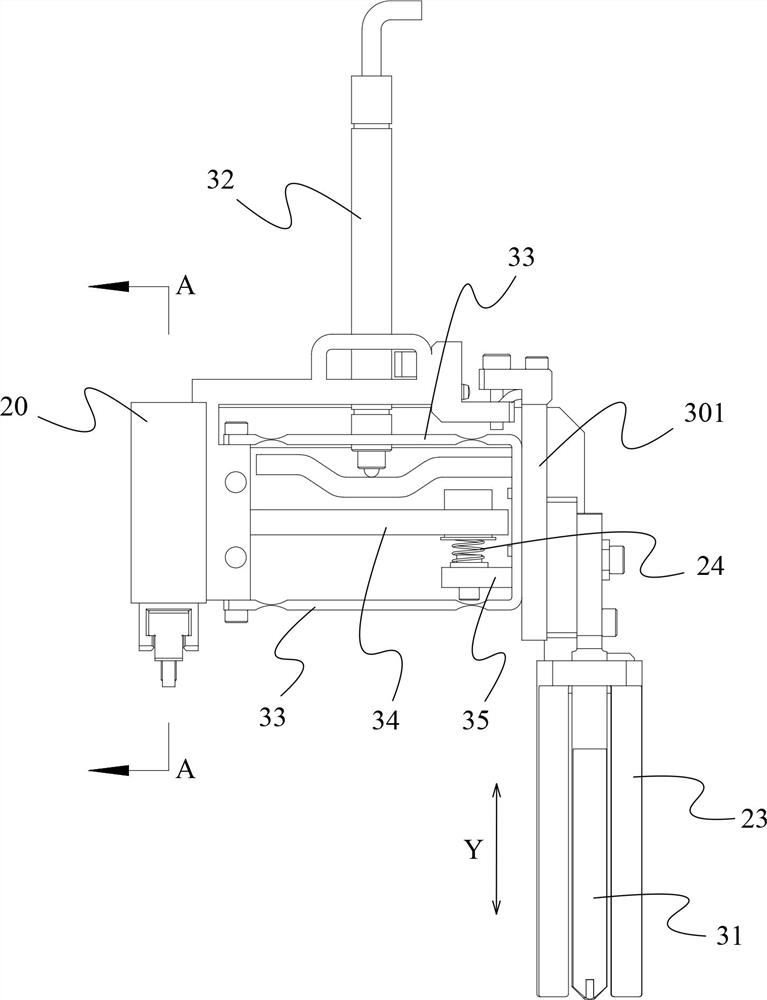

[0027] like figure 2 As shown, the present application provides a measuring unit for a vortex groove measuring platform, and the measuring unit includes a base 10 , a movable seat 20 and an elastic measuring mechanism 30 . Wherein, the base 10 can be fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com