Bilateral automatic refueling robot and control method

A technology of robot and refueling mechanism, which is applied in special dispensing devices, packaging, dispensing devices, etc., can solve the problems of poor matching precision between the refill port and the fuel tank port, low degree of automation, and low refill efficiency, so as to improve flexibility and Applicability, improving the degree of automation and safety and reliability, and improving the effect of success rate and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

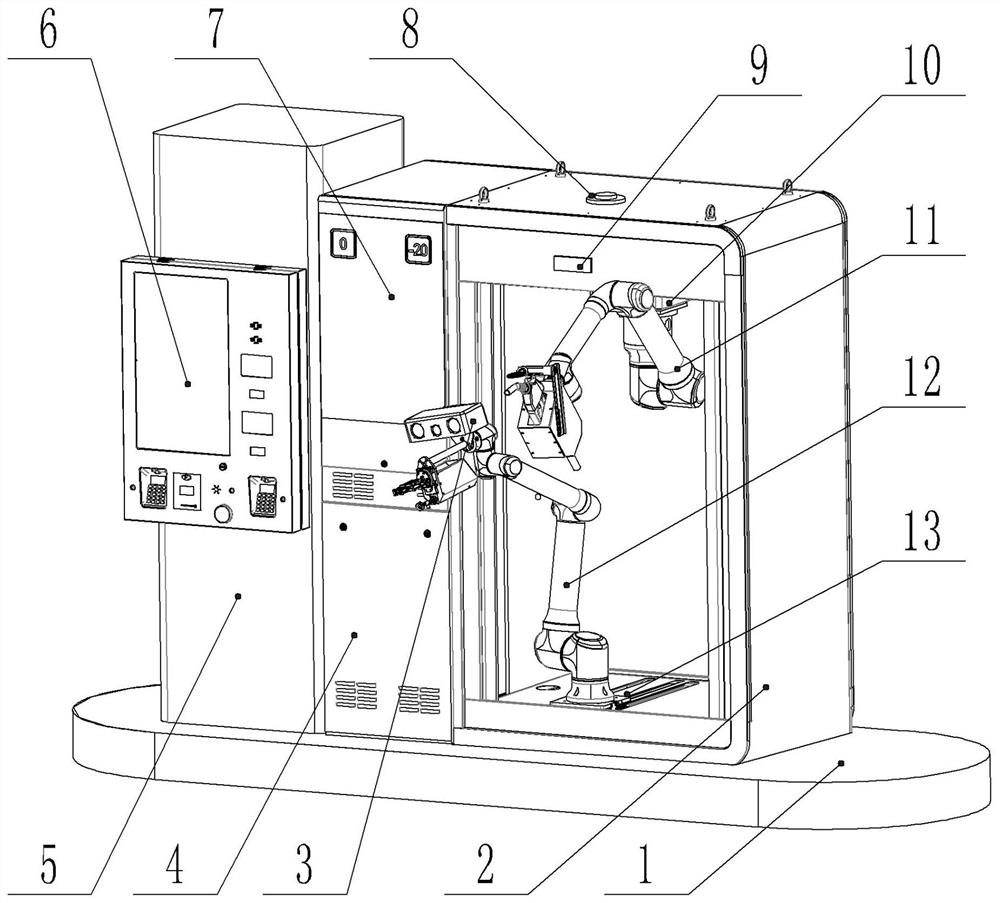

[0047] Embodiment 1: a kind of bilateral refueling robot, see Figure 2 to Figure 5 , including a refueling cabin 2, a guide mechanism, a visual identification mechanism, a fuel tank cap opening and closing mechanism 12 and a refueling mechanism 11.

[0048] The guide mechanism includes a second guide assembly with the same structure, and the positions are respectively corresponding to the first guide assembly arranged at the bottom and the top of the fuel tank 2; The bracket for the motor to move laterally and the mounting column for connecting the opening and closing mechanism 12 of the fuel tank cap or the fueling mechanism 11 are arranged on the bracket.

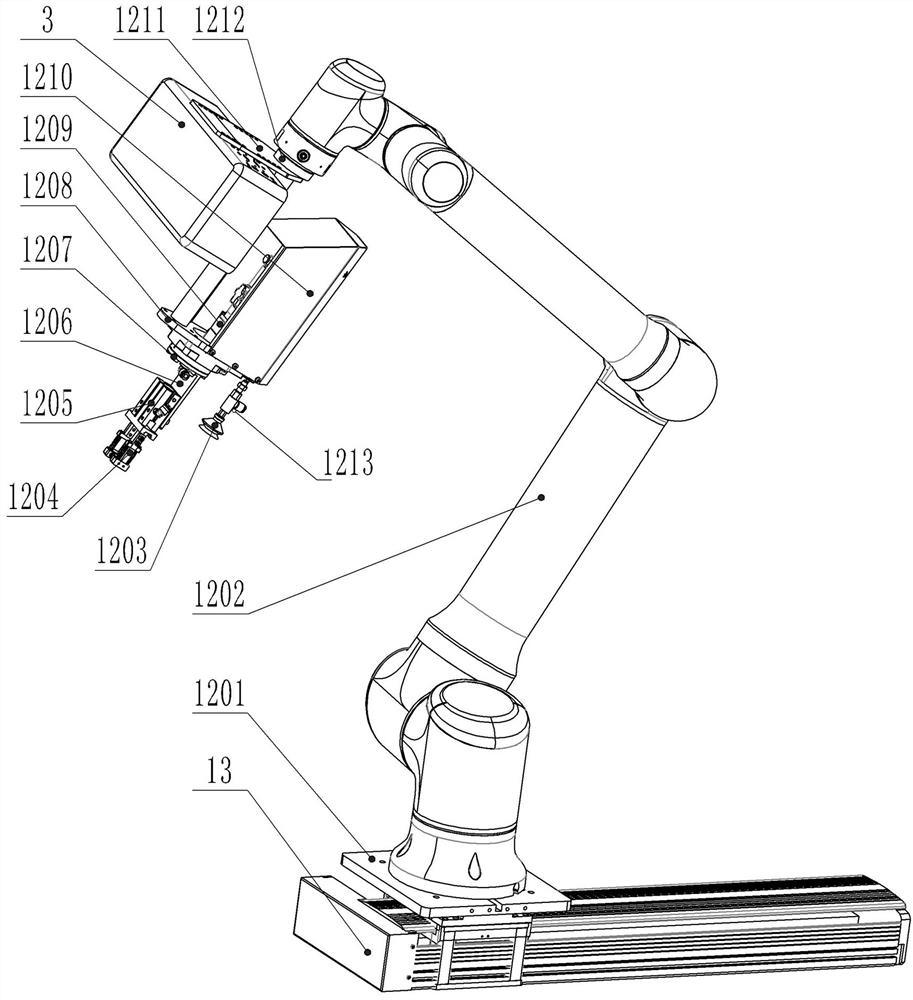

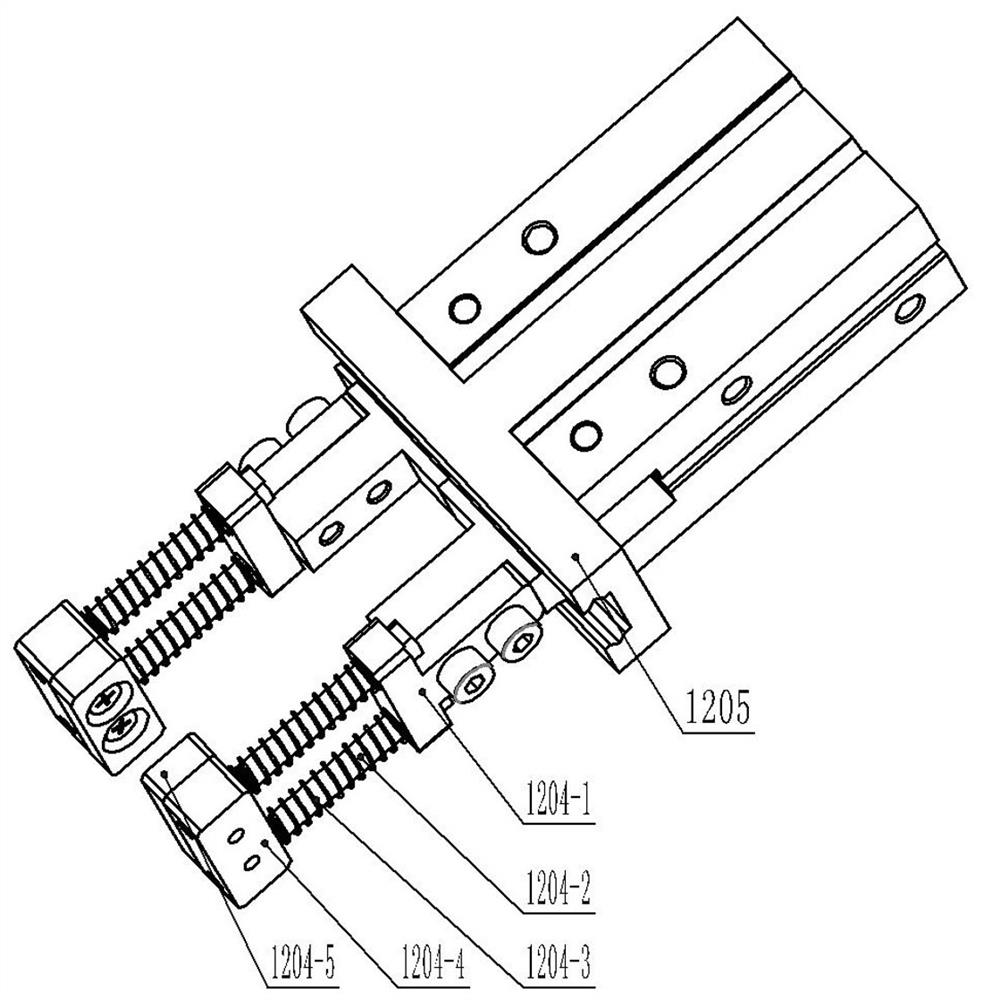

[0049] The fuel tank cap opening and closing mechanism 12 includes a first six-axis mechanical arm 1202 installed on the mounting column of the first guide assembly, and a fuel tank cap opening and closing assembly connected to the top of the first six-axis mechanical arm 1202; The sixth joint shaft connected to the top...

Embodiment 2

[0056] Embodiment 2, a kind of automatic refueling device, see Figure 1 to Figure 5 , including the refueling island 1, the column 5 set on the refueling island 1, the above-mentioned bilateral refueling robot, the electric box control cabinet 7, the refueling metering box 4, the human-computer interaction / payment module 6, the automatic fire extinguishing module 8, and the filling safety module 9 and refueling operation control system; the refueling robot, visual monitoring components, electric box control cabinet 7, refueling metering box 4, human-computer interaction / payment module 6, temperature sensor (TR50), smoke detector (JK / SS168) All are electrically connected with the control system.

[0057] The filling safety protection module 9 includes a visual monitoring device and a visual monitoring control module. The visual monitoring device is installed on the shells on both sides of the refueling cabin 2. The visual monitoring control module is installed in the electric ...

Embodiment 3

[0061] Embodiment 3, a kind of automatic refueling method: comprises the following steps:

[0062]S1, after the man-machine exchange module receives the order from the customer, the control system controls the opening and closing mechanism 12 of the fuel tank cap and the refueling mechanism 11 to drive them to the side where the order is generated through the traverse motor provided on the slide rail.

[0063] S2, the 3D vision 3 scanning mechanism starts to scan the fuel tank cover of the vehicle, and the electric push rod 1213 on the first six-axis mechanical arm 1202 extends until the vacuum suction cup 1203 touches the fuel tank cover, and the air machine moves into the vacuum suction cup 1203 Inject compressed air to form a negative air pressure to suck the outer cover tightly, and the electric push rod 1213 shrinks to drive the outer cover to open; 3D vision 3 scans the inner cover of the fuel tank, and the first six-axis mechanical arm 1202 drives the gripper assembly 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com