Emulsifying method for sizing agent

A sizing agent and gelatinization technology, which is applied in the field of papermaking, can solve the problems of large starch consumption, high process cost, and influence on the wide application of sizing agent, and achieve the effect of reducing process cost and improving flexibility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

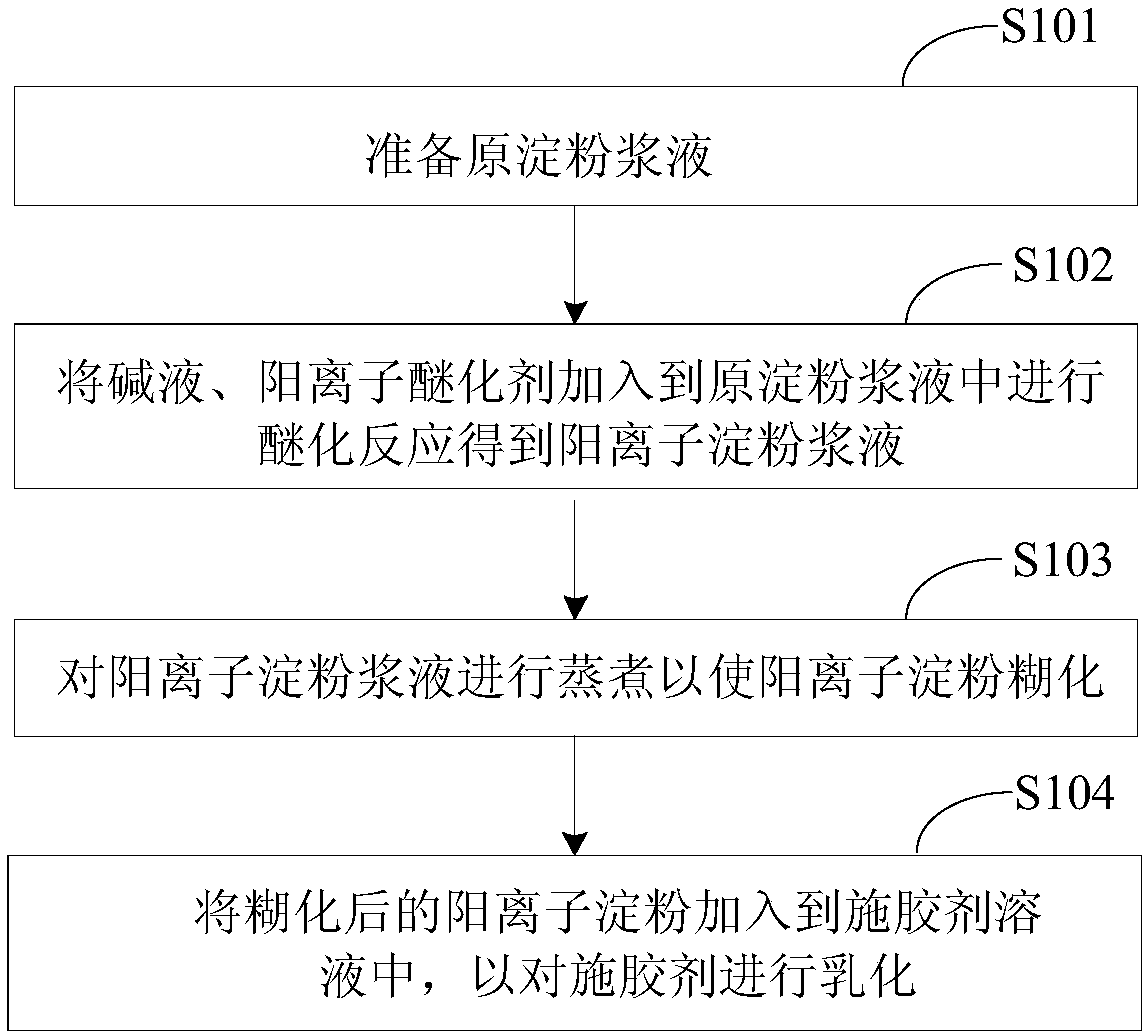

Method used

Image

Examples

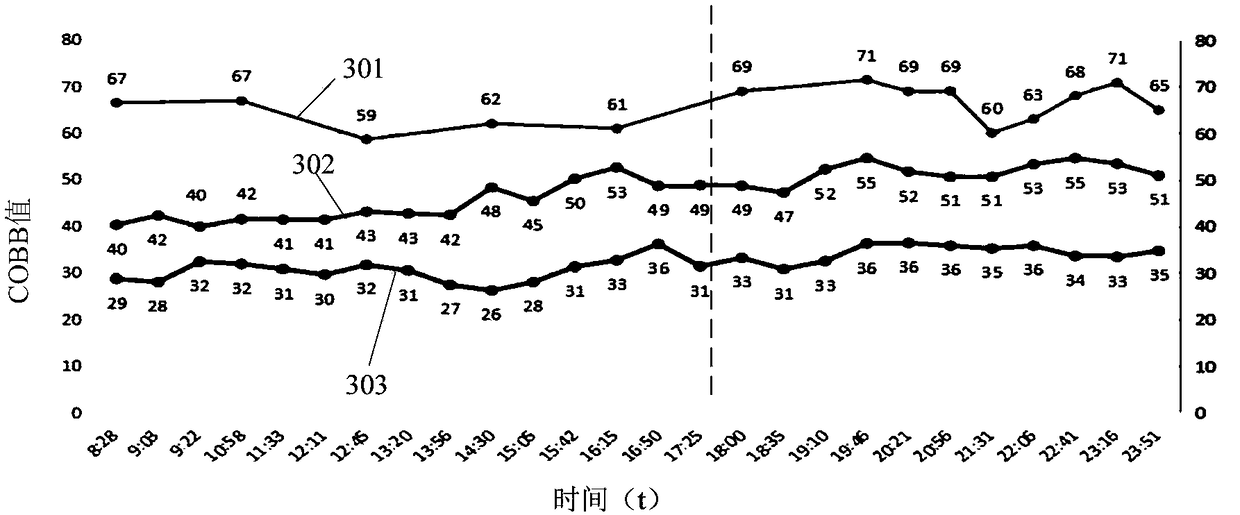

experiment example 1

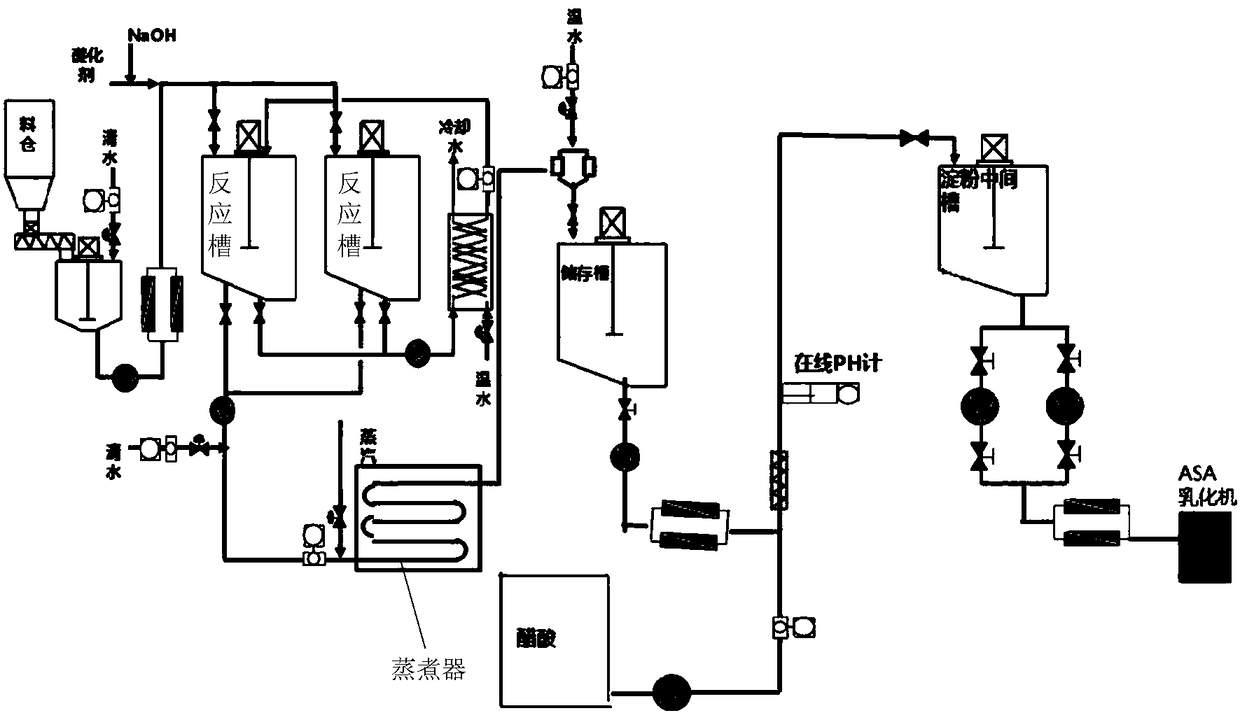

[0056] Weigh 10Kg of cassava raw starch and feed it to the silo by driving, add clear water to dissolve and dilute to 40% concentration, and then transfer it to the reaction tank; put the etherification agent with a ratio of 28% relative to the original starch and NaOH with a ratio of 30% relative to the etherification agent on-line After mixing evenly, put it into the reaction tank; the starch in the reaction tank uses a heat exchanger to exchange heat, so that the starch solution in the reaction tank is heated to 45-50 ° C in a circular manner, and the pH of the starch solution is continuously monitored at about 11-11.5, and the reaction is 8-12 hours; After diluting the reacted starch to a concentration of 8%, the starch is cooked by a cooker, and the cooking temperature is controlled to be 130° C., and the cooking pressure is 2KPa, so that the starch is completely gelatinized. After the cooking is completed, it is transferred to the starch storage tank. Use a filter to filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com