Server with maintenance prediction function, and system

A server and functional technology, applied in the fields of instruments, measuring devices, special data processing applications, etc., can solve the problems of waste of manpower and material resources, affecting the accuracy of judgment, and obvious differences between equipment status and operation, and achieve the effect of overcoming strong subjectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

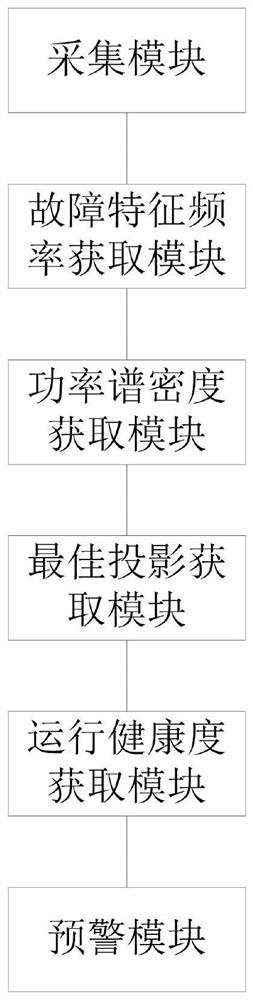

[0084] figure 1 It is a functional block diagram of the server with maintenance prediction function involved in the present invention.

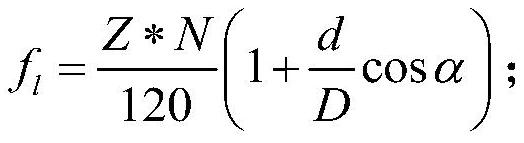

[0085] Such as figure 1 As shown, this embodiment 1 provides a server with a maintenance prediction function, including: an acquisition module to collect parameter data for predictive maintenance of wave generators; a fault characteristic frequency acquisition module to obtain the frequency of wave generator bearings according to the parameter data The fault characteristic frequency; the power spectral density acquisition module, obtains the circular autocorrelation function and power spectral density of the vibration signal in the parameter data according to the fault characteristic frequency; the optimal projection acquisition module, obtains the best one-dimensional space according to the sample data of the power spectral density The projection direction; the operation health degree acquisition module predicts the wave generator operation...

Embodiment 2

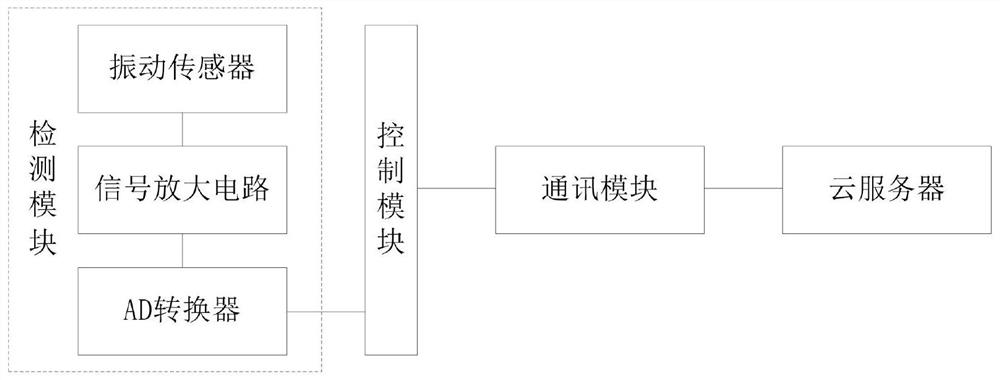

[0136] figure 2 It is a functional block diagram of the wave generator predictive maintenance system involved in the present invention.

[0137] Such as figure 2 As shown, on the basis of embodiment 1, this embodiment 2 also provides a wave generator predictive maintenance system, including: a wave generator and a cloud server; the wave generator is suitable for collecting parameter data of the body, and The parameter data is sent to the cloud server; the cloud server is suitable for predicting the operation health of the wave generator according to the parameter data, and giving an early warning according to the operation health of the wave generator.

[0138] In this embodiment, the cloud server is suitable for adopting the server with the maintenance prediction function in Embodiment 1 to predict the operation health of the wave generator, and give an early warning to the operation of the wave generator according to the health of the wave generator.

[0139] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com