Quick and batch clamping jig for linear cutting machining

A wire cutting and jig technology, which is used in the field of fast and batch clamping fixtures, can solve the problems of inability to guarantee the centring error, wasting time, and cumbersome processes, so as to reduce the time for calibration and centring, with good effects and lightening The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention proposes a fast and batch clamping jig for wire cutting.

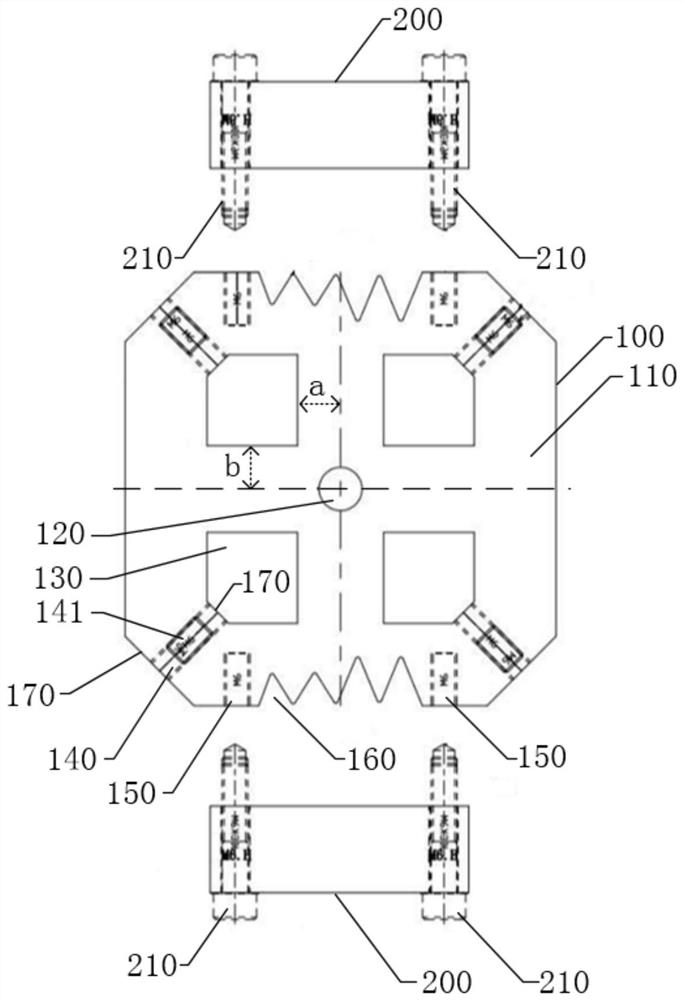

[0018] refer to figure 1 , figure 1 It is a schematic diagram of dismantling the top view structure of an embodiment of the present invention.

[0019] Such as figure 1 As shown, in the embodiment of the present invention, the fast and batch clamping jig for wire cutting includes: a jig body 100 with a square clamping surface 110 and an auxiliary fixture body 100 detachably connected 200 pieces.

[0020] The center of the clamping surface 110 is provided with a center zero hole 120, and the inner sides of the four right-angled sides of the clamping surface 110 are provided with square holes 130 for placing square inserts. The centers of the zero hole 120 coincide, and the surrounding sidewalls of the square hole 130 are parallel to the surrounding sidewalls of the jig body 100 . The side length of the square hole 130 is not less than 20mm, and a square insert with a side length≤20×20mm can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com