Distribution network hot-line work wire lifting device

A live working and lifting device technology, which is applied in the direction of lifting devices, fixing devices, overhead lines/cable equipment, etc., can solve the problems of laborious lifting, high labor intensity, and low level of automation, so as to reduce risks and improve the efficiency of live working Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

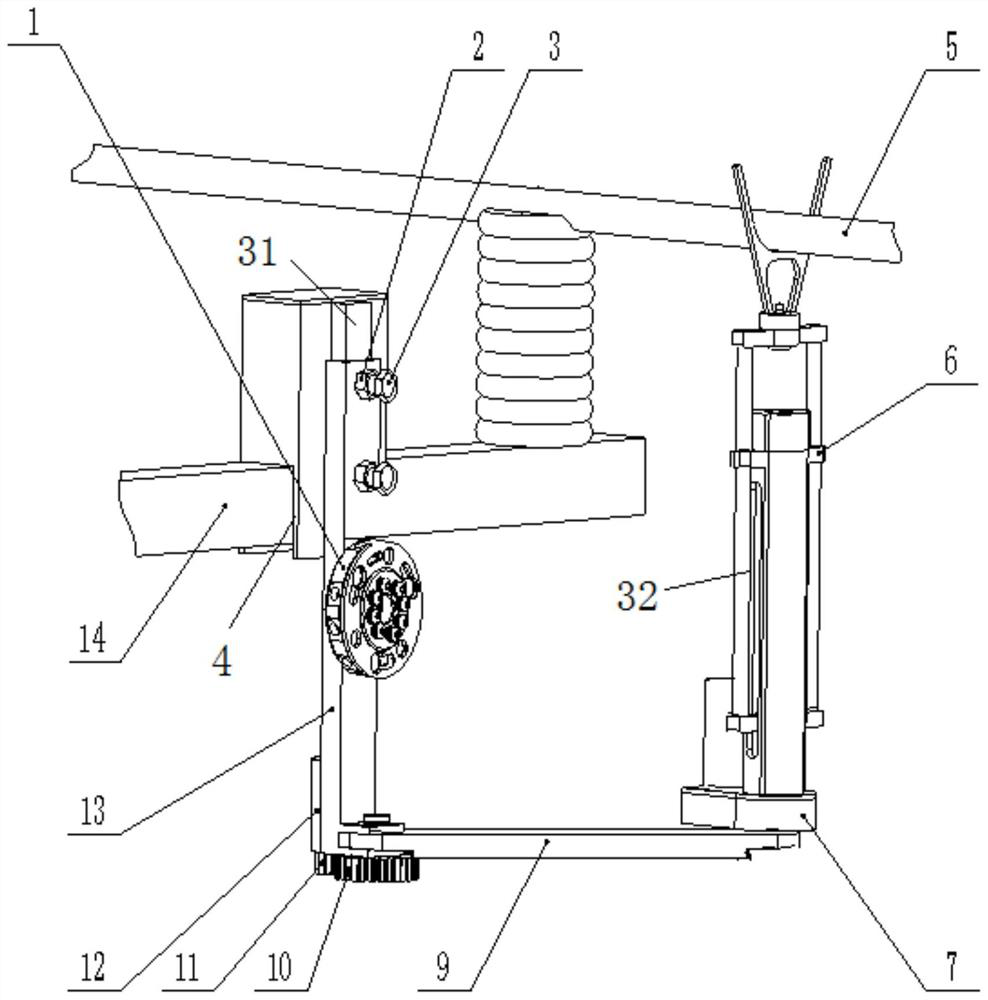

[0034] Such as figure 1 , 2 , 3, and 4, a wire lifting device for live work in distribution networks, including a magnetic adsorption positioning and clamping mechanism, a swing arm adjustment mechanism, and a jacking mechanism; each part is described in detail below:

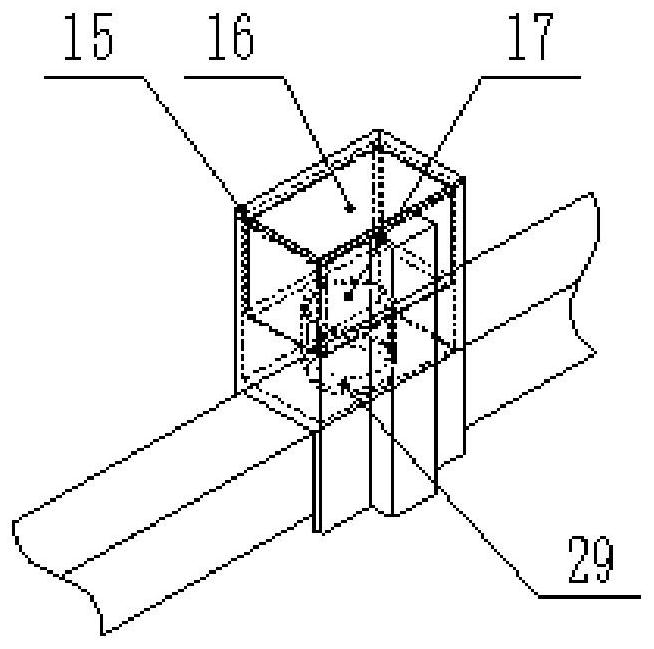

[0035] The magnetic adsorption positioning and clamping mechanism includes a clamping and positioning base 15, an electromagnet 17 and a vertical beam 13. In this embodiment, the bottom of the clamping and positioning base 15 forms a U-shaped groove 4, which can be straddled on the cross arm 14 , convenient for clamping and positioning, and its opening size can be adjusted according to the cross-arm 14 on site;

[0036] The electromagnet 17 is arranged inside the clamping and positioning base 15. It is a strong magnetic force electromagnet, which can be firmly adsorbed on the cross arm 14, and contacts the cross arm 14 through a magnetic conductor 29. One side of the clamping and positioning base 15 is provide...

Embodiment 2

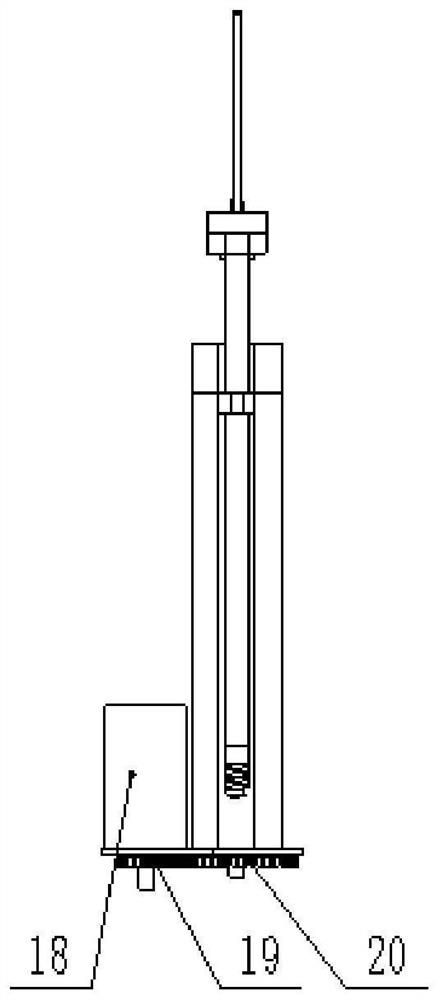

[0046] Such as figure 2 , 3 , 5, and 6, the lifting device for live wires in distribution networks provided by this embodiment is a further improvement on Embodiment 1, and also includes a second drive mechanism that can drive the base compared to Rotate on the beam; Specifically, the second drive mechanism includes a second drive motor 8, the second drive motor is installed below the beam, and its output end is fixedly connected to the base, the lower part of the base The tapered roller bearing 30 is in contact with the beam, and the second drive motor 8 is used to drive the jacking mechanism to rotate relative to the beam 9, and the jacking frame 21 is adjusted to lift the wire 5 at an optimal angle;

[0047] Further, it can be considered that the control module 16 is connected in communication with the second drive motor 8 and controls the operation of the second drive mechanism.

[0048] Other structures of this embodiment are the same as those of Embodiment 1, so detai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com