Automatic curling machine

A crimping machine, automatic technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of inaccurate sewing stitches, poor processing effect, large error in the length of the legs, etc., and achieve smooth process and solution. Effects of low levels of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

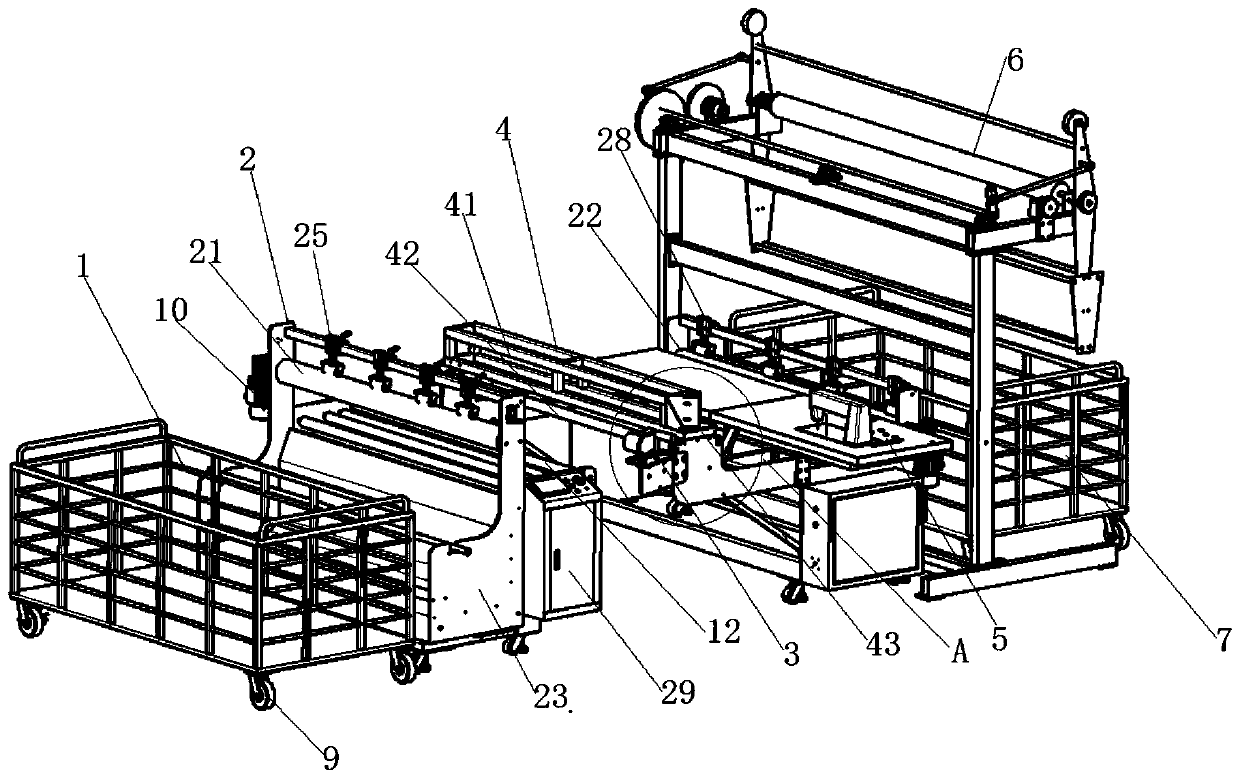

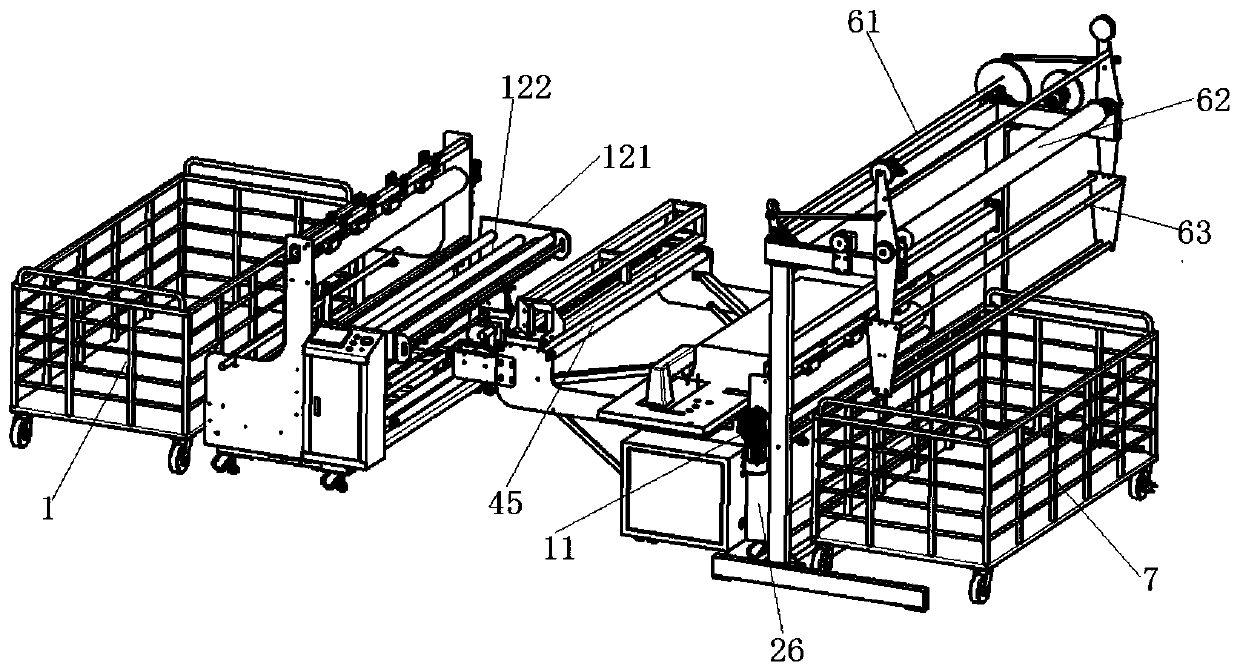

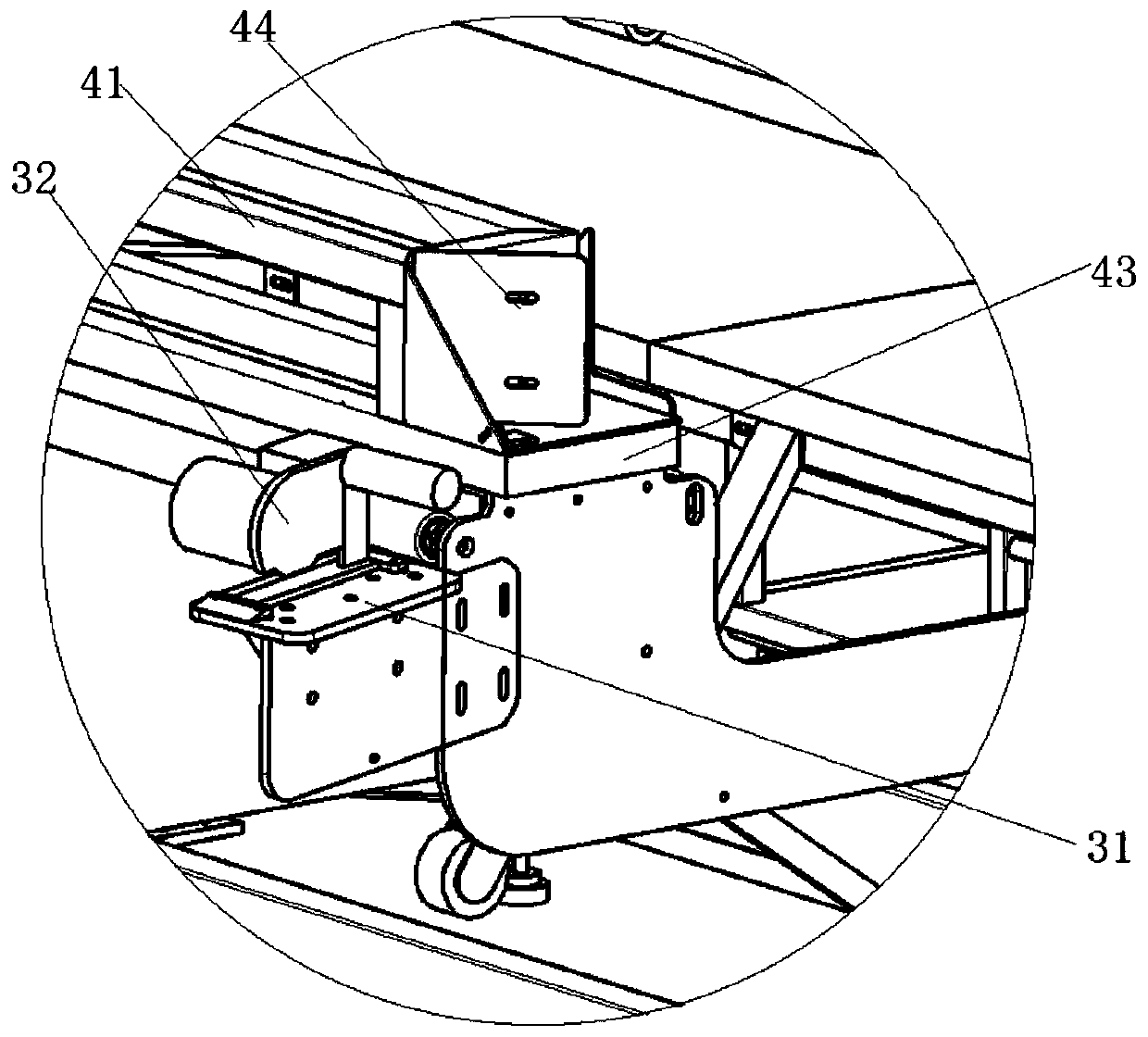

[0022] Such as Figure 1-4 As shown, the automatic crimping machine provided by the present invention includes a front material car 1, a feeding mechanism 2, an automatic trimming mechanism 3, an automatic hemming mechanism 4, a sewing mechanism 5, a material receiving mechanism 6 and a rear material car 7, the The cloth 8 in the front material cart 1 is transported to the automatic edge folding mechanism 4 arranged on the rear side of the feeding mechanism 2 through the front traction roller 21 arranged on the feeding mechanism 2, and the automatic edge trimming mechanism 3 is arranged in front of the automatic edge folding mechanism 4 Side, used to cut off the excess cloth 8 transported to the automatic hemming mechanism 4, the automatic hemming mechanism 4 is connected with the sewing mechanism 5, and the rear traction roller 22 of the feeding mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com