Low-abrasion combined four-way valve

A combined, four-way valve technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problem of high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

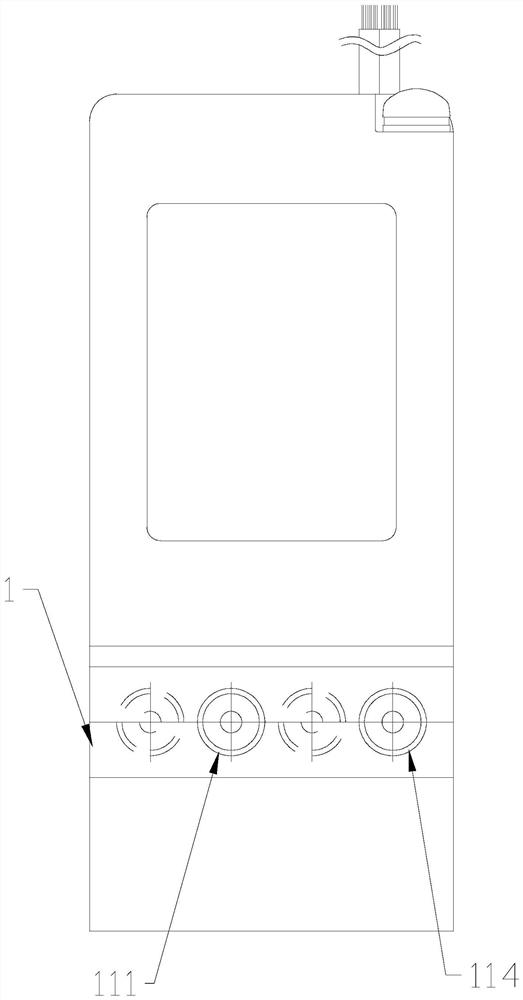

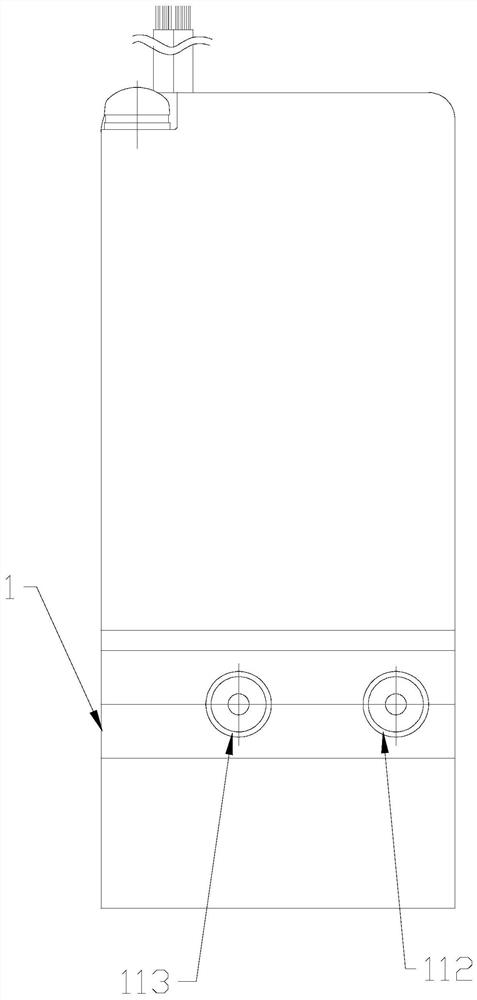

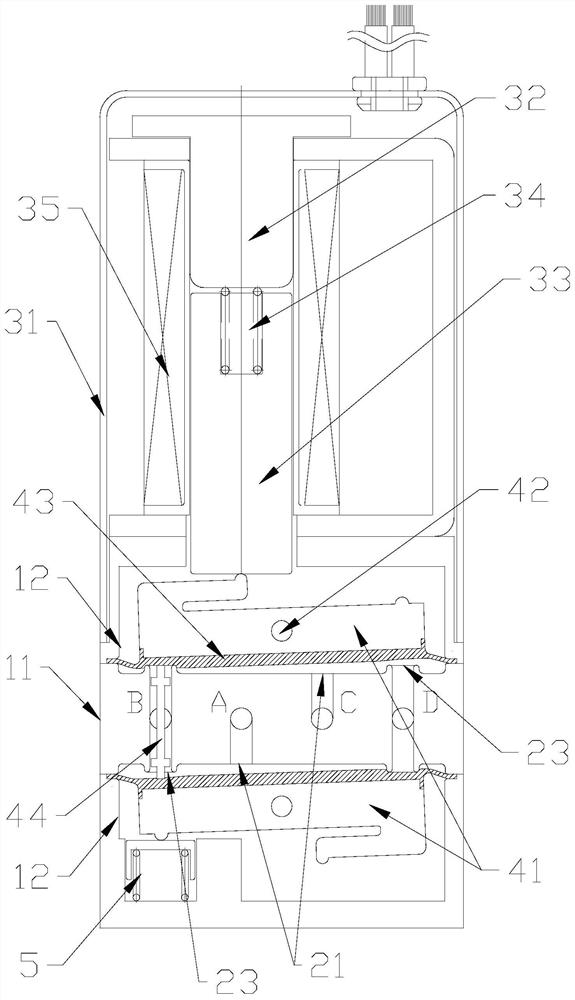

[0027] See attached Figure 1-6 As shown, a low-wear combined four-way valve of the present invention includes a valve body 1, and two valve cavities are arranged oppositely in the valve body 1, and each valve cavity is provided with an internal communication valve. A normal opening 21, a No. 1 opening and closing port 22, and a No. 2 opening and closing port 23. The valve body 1 is also provided with A port 111, B port 112, C port 113, D port 114, the A port 111 communicates with one of the normal openings 21, the C port 113 communicates with the other normal opening 21, and the B port 112 communicates with the No. 1 opening and closing port 22, The No. 2 opening and closing port 23 of the other valve chamber communicates, and the D port 114 communicates with the No. 2 opening and closing port 23 of one valve chamber and the No. 1 opening and closing port 22 of the other valve chamber. The valve body 1 is also provided with a link rocker mechanism driven by the electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com