Carrier tape conveying membrane compounding equipment and compounding method

A technology for composite equipment and conveying film, which is applied in chemical instruments and methods, cleaning methods and appliances, cleaning methods using gas flow, etc., can solve problems such as high cost, unfavorable production and sales, and affecting the yield of heat sealing process, etc. Achieve the effect of ensuring safety and reliability, improving efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

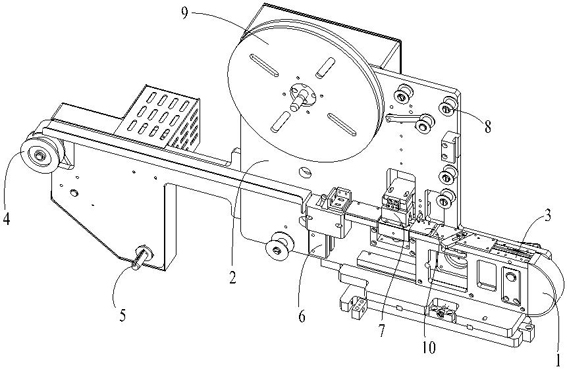

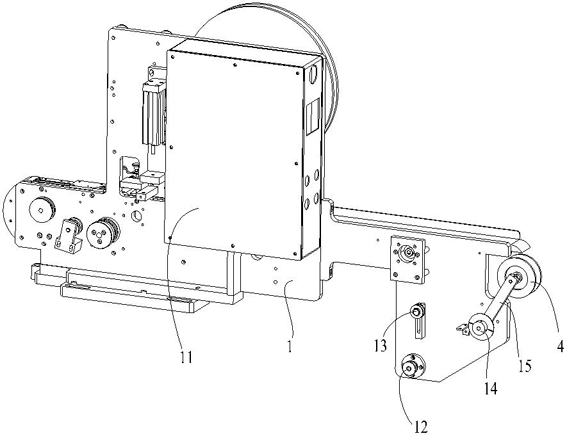

[0030] Such as figure 1 with figure 2 Shown: in order to realize the dedusting and compacting of the diaphragm, and improve the efficiency and yield of the compounding of the film material, the present invention includes a film material loading and unloading mechanism for loading the film material, a loading and unloading mechanism for transporting the matrix film Belt conveying mechanism 3, heat-sealing mechanism 7 for heat-sealing and compounding, and membrane composite storage mechanism for storing composite membranes;

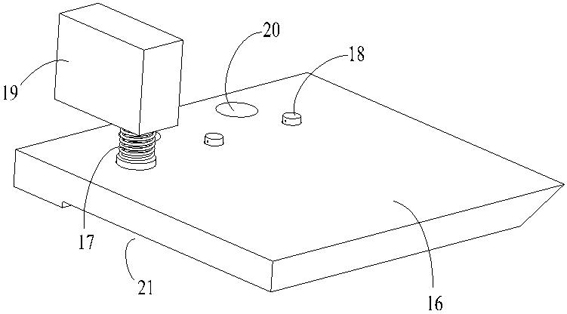

[0031] It also includes a diaphragm pressing and dust removal mechanism 10, which compresses and fits the loaded film released from the film material loading and unloading mechanism on the base film conveyed by the carrier belt conveying mechanism 3. In the process of compressing the material-carrying film and the matrix film, the film-pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap