Hot-rolled weather-resistant angle steel tower

An angle steel tower and weather-resistant technology, which is applied to towers, ladders, building types, etc., can solve the problems of destroying the stability of the angle steel tower, and the angle steel tower is not equipped with anti-climbing devices, so as to facilitate the installation and maintenance of equipment, avoid the risk of falling, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

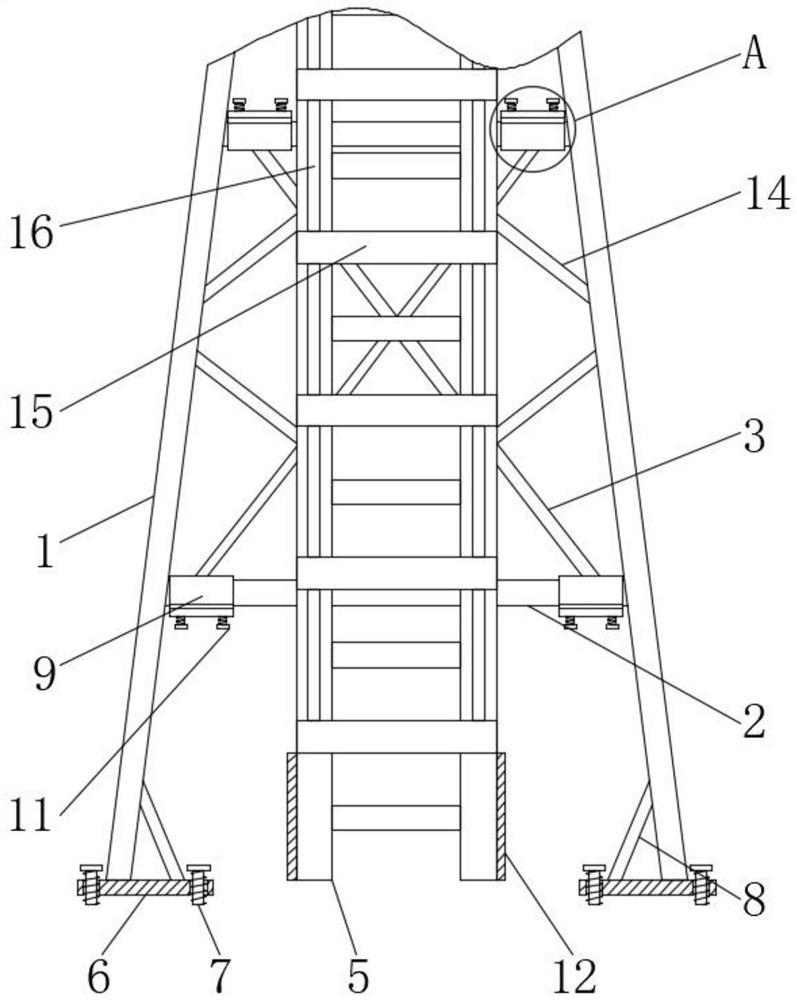

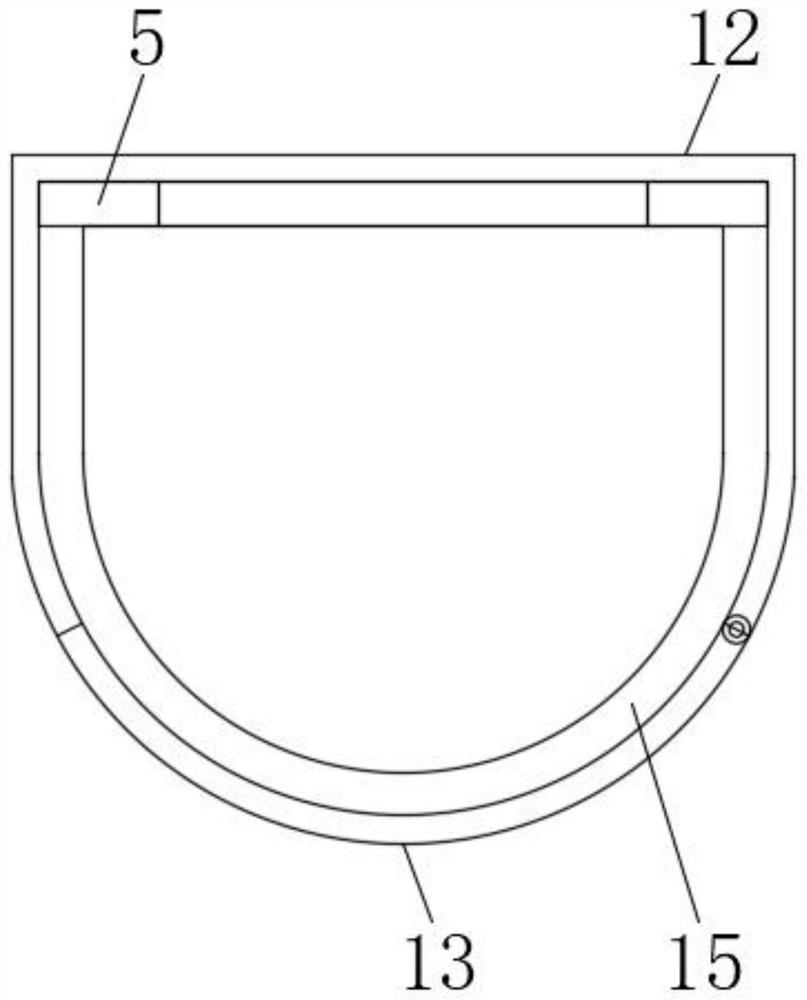

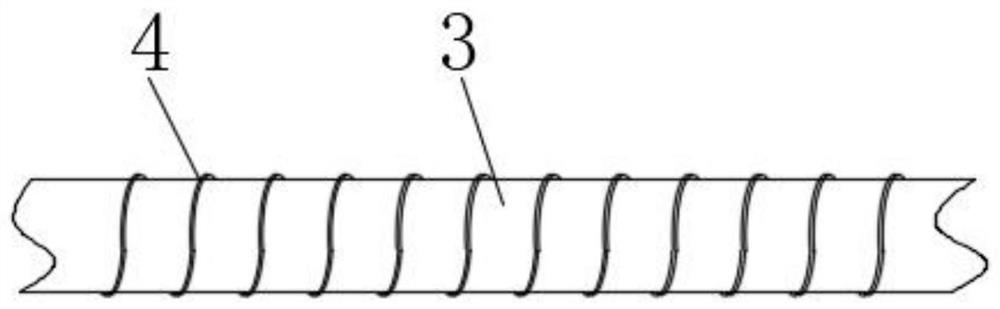

[0026] The present invention provides Figure 1-5 As shown, a hot rolled weather-resistant angle steel tower includes a tower 1, and the bottom fixing of the tower 1 is fixedly mounted, and the mounting assembly includes a fixing plate 6 fixed to the bottom of the tower 1, a surface thread connection of the fixed plate 6. There is a fixed plug 7, the bottom of the fixed plug 7 penetrates the fixing plate 6 and extends below the fixing plate 6, the tower 1 is inclined inwardly, and the surface of the tower 1 is welded with a fixed bar 8, and the fixing rod 8 is inclined. The fixing lever 8 is away from one end of the tower 1 and the surface of the fixing plate 6;

[0027] Through the arrangement of the tower 1, the entire angle steel tower can be used to fix the support, and the role of the angle steel tower can be loaded. By the installation of the assembly, the entire corner steel tower can be fixed to the mounting base, which is described herein. The mounting base has a reinforce...

Embodiment 2

[0029] The present invention provides Figure 1-5 As shown, a hot rolled weather-resistant angle steel tower includes a tower 1, and the bottom fixing of the tower 1 is fixedly mounted, and the mounting assembly includes a fixing plate 6 fixed to the bottom of the tower 1, a surface thread connection of the fixed plate 6. There is a fixed lever 8, and the bottom portion of the fixing lever 8 is passed through the fixing plate 6 and extends below the fixing plate 6, the tower 1 is inclined inwardly, and the surface of the tower 1 is welded with a fixed bar 8, and the fixing rod 8 is inclined. The fixing lever 8 is away from one end of the tower 1 and the surface of the fixing plate 6;

[0030] Through the arrangement of the tower 1, the entire angle steel tower can be used to fix the support, and the role of the angle steel tower can be loaded. By the installation of the assembly, the entire corner steel tower can be fixed to the mounting base, which is described herein. The mountin...

Embodiment 3

[0036] The present invention provides Figure 1-5As shown, a hot rolled weather-resistant angle steel tower includes a tower 1, and the bottom fixing of the tower 1 is fixedly mounted, and the mounting assembly includes a fixing plate 6 fixed to the bottom of the tower 1, a surface thread connection of the fixed plate 6. There is a fixed lever 8, and the bottom portion of the fixing lever 8 is passed through the fixing plate 6 and extends below the fixing plate 6, the tower 1 is inclined inwardly, and the surface of the tower 1 is welded with a fixed bar 8, and the fixing rod 8 is inclined. The fixing lever 8 is away from one end of the tower 1 and the surface of the fixing plate 6;

[0037] Through the arrangement of the tower 1, the entire angle steel tower can be used to fix the support, and the role of the angle steel tower can be loaded. By the installation of the assembly, the entire corner steel tower can be fixed to the mounting base, which is described herein. The mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com