Integrated black equipment based on bidirectional reflection function layer compensation

A bidirectional reflection, functional layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of incomplete black screen, poor effect, poor effect of one black screen, etc., and achieve the effect of solving the problem of black screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

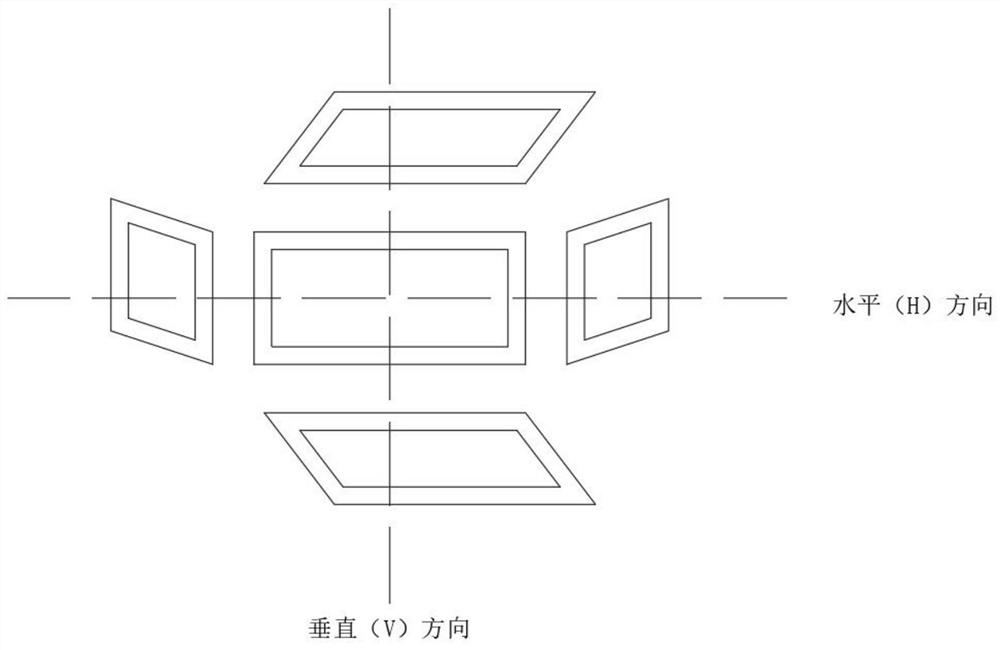

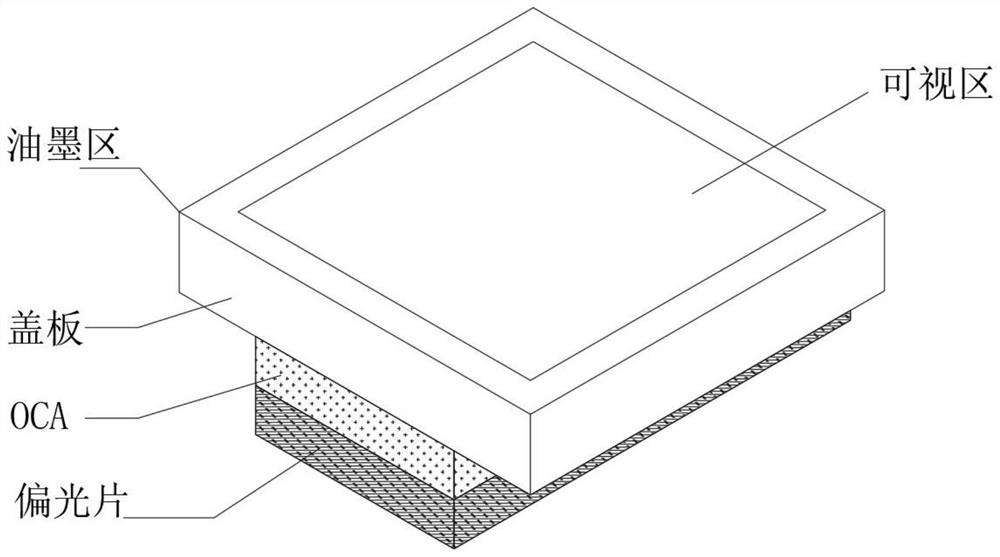

[0025] see Figure 1-Figure 8 As shown, this embodiment provides an integrated black device based on bidirectional reflection functional layer compensation, including a cover plate, ink, OCA, upper polarizer, liquid crystal color filter glass, glass substrate and functional film;

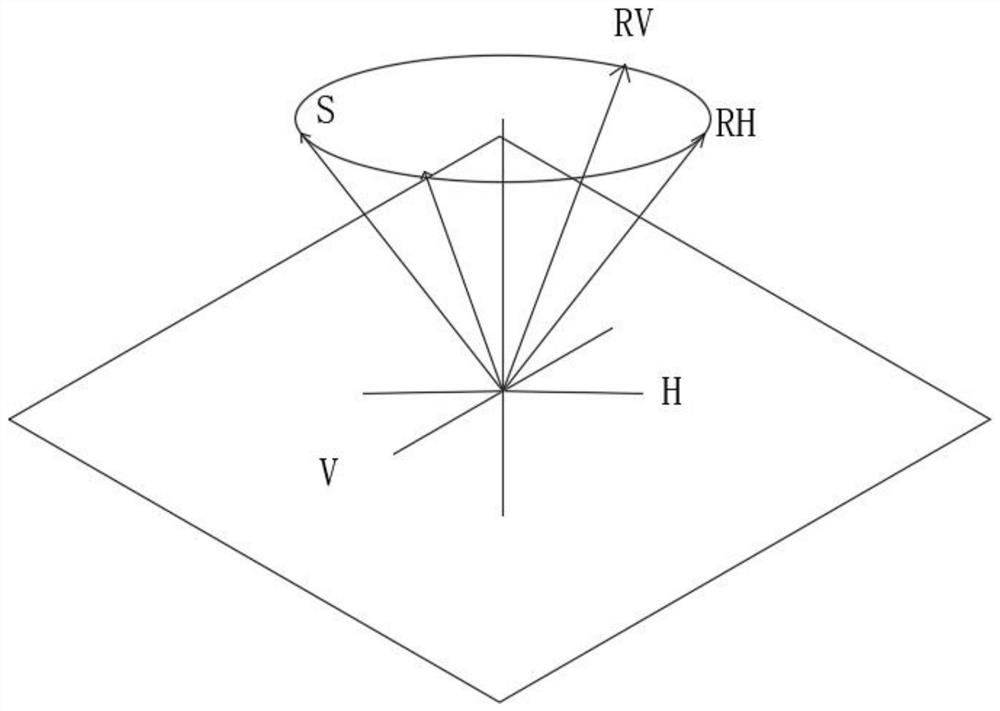

[0026] The functional film includes base material 1, double reflective layer, base material 2 and pressure-sensitive adhesive. Base material 1, double reflective layer, base material 2 and pressure-sensitive adhesive are attached sequentially from top to bottom. The reflectivity of the product in all directions is consistent. At this time, according to the traditional scheme, adjust the reflectivity and chromaticity value of the ink area, and the overall black effect in different directions can be improved;

[0027] There are functional areas and non-functional areas on the top of the cover, and the functional film is attached to the outside of the cover.

[0028] In this embodiment, an AGARAF laye...

Embodiment 2

[0049] To reflect another application structure of functional membranes, please refer to Figure 9 shown, where:

[0050] Attach or coat the functional film or make it on the underside of the cover by other methods. At this time, the size only needs to be larger than the visible area. In this structure, in order to obtain a better "black" effect, it can also be placed on the cover An anti-reflection layer is made on the outside of the board, which can be achieved by attaching a functional film or sputtering a film layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com