Automatic machining equipment for chain saw carburetor body

A technology for processing equipment and carburetors, which is applied in the field of automatic processing equipment for chainsaw carburetor bodies, can solve problems such as reducing workpiece production efficiency, misprocessing workpieces, and position offsets, so as to improve processing efficiency, save power resources, Avoid false trigger effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

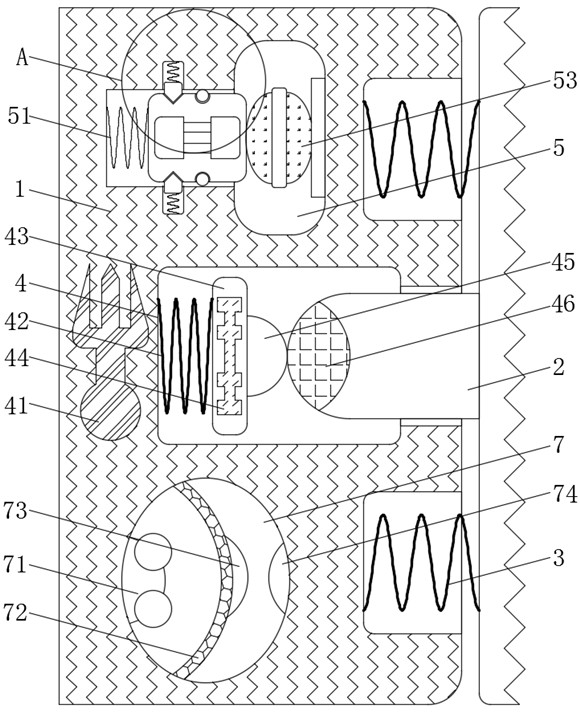

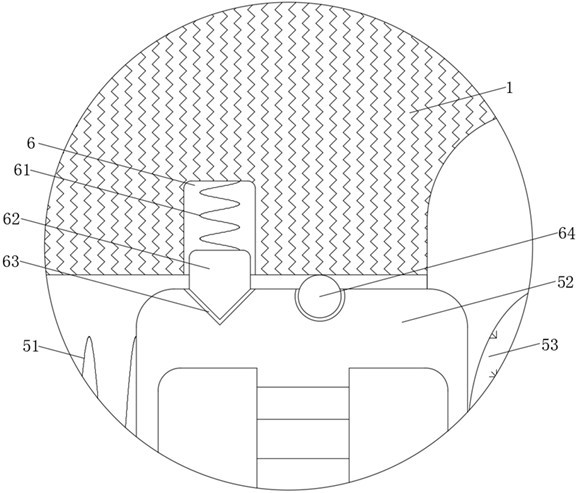

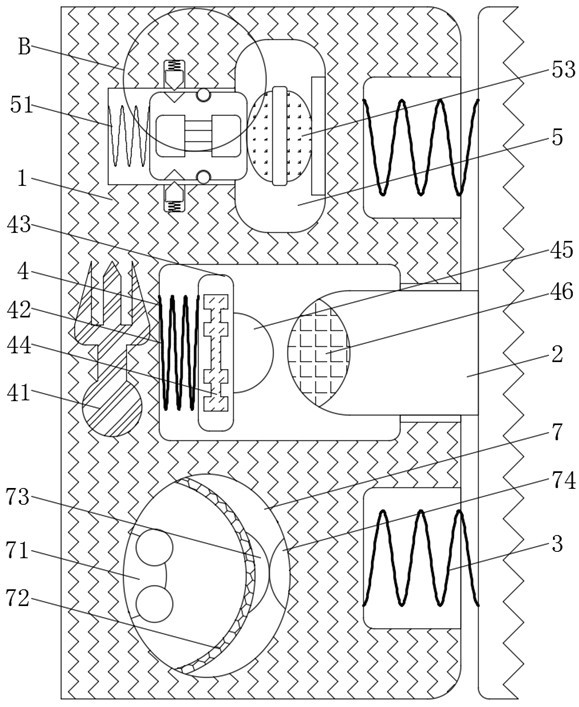

[0023] see Figure 1-4 , a chainsaw carburetor body automatic processing equipment, including a fixed frame 1, the fixed frame 1 plays the role of fixing the parts, the right side of the fixed frame 1 is movably connected with a clamping plate 2, the clamping plate 2 plays a role in contact with The function of contacting and clamping the processing parts, the right side of the fixed frame 1 is fixedly connected with the spring one 3 fixedly connected with the left side of the clamping plate 2, and the spring one 3 plays the role of extending the clamping plate 2 to the right The middle part of the fixed frame 1 is fixedly connected with a disconnecting mechanism 4, and the disconnecting mechanism 4 plays the role of disconnecting the circuit of the processing equipment. Play the role of using its own mechanical energy to generate electric energy, effectively saving electric energy, the top inner wall of the fixed frame 1 is fixedly connected with the stabilizing mechanism 6 p...

Embodiment 2

[0030] see Figure 1-4 , a chainsaw carburetor body automatic processing equipment, including a fixed frame 1, the fixed frame 1 plays the role of fixing the parts, the right side of the fixed frame 1 is movably connected with a clamping plate 2, the clamping plate 2 plays a role in contact with The function of contacting and clamping the processing parts, the right side of the fixed frame 1 is fixedly connected with the spring one 3 fixedly connected with the left side of the clamping plate 2, and the spring one 3 plays the role of extending the clamping plate 2 to the right The middle part of the fixed frame 1 is fixedly connected with a disconnecting mechanism 4, and the disconnecting mechanism 4 plays the role of disconnecting the circuit of the processing equipment. Play the role of using its own mechanical energy to generate electric energy, effectively saving electric energy, the top inner wall of the fixed frame 1 is fixedly connected with the stabilizing mechanism 6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com