Continuous firing mechanism of paintball gun

A technology of paintball guns and continuous firing, applied in the field of paintball guns, which can solve the problems of low gas utilization rate, poor precision, low initial velocity, etc., and achieve good shooting reliability, applicable range of use, and good timeliness of ammunition supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

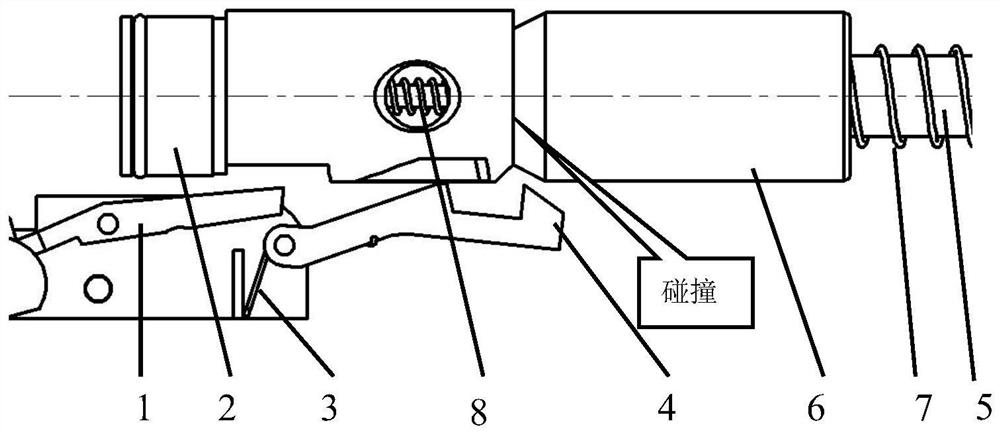

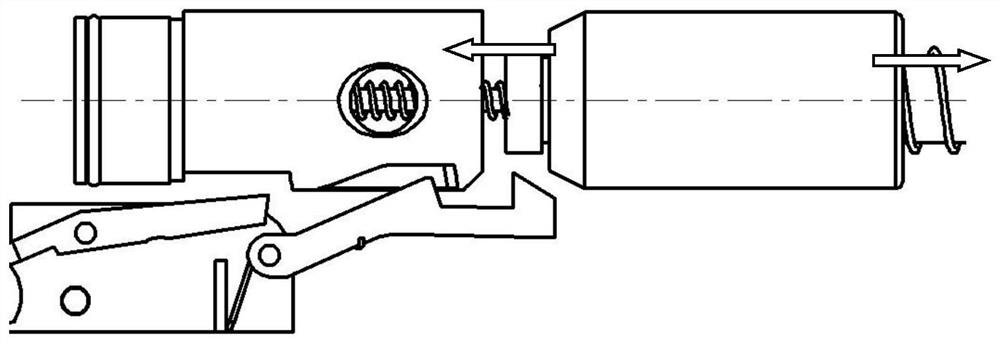

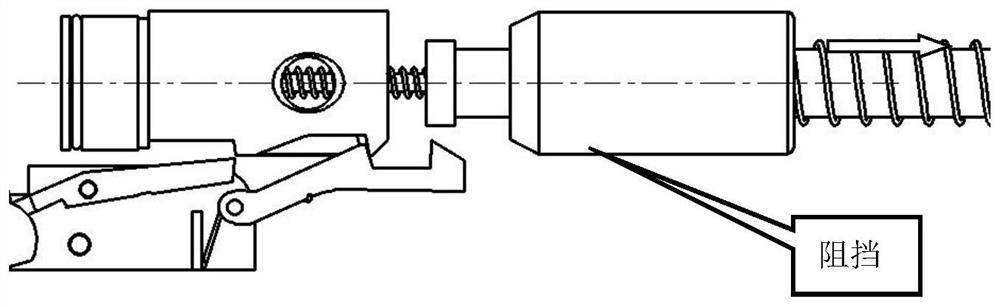

[0023] see Figure 1-Figure 4 , which is a paintball gun burst mechanism, including a stub 1, a hammer 2, and the hammer 2 is driven by a hammer spring 8 to return, and also includes a delay body 6, and the delay body 6 is slidably fitted on the On the recoil spring guide rod 5, and through the time delay body recoil spring 7 set on the recoil spring guide rod 5, the recoil is driven. The iron 4 is driven back and forth by the continuous firing stubbing spring 3, the lower end of the hammer 2 is provided with a bar-shaped groove, and the free end of the continuous firing stubbing iron 4 is provided with an upwardly protruding blocking part and a pressing part. A space is formed between the blocking part and the pressing part, which is used to make way for the lower part of the rear end of the hammer 2. The front end of the blocking part is provided with an inclined surface, which is used to cooperate with the rear end of the hammer 2 to press down and fire continuously. The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com