Shell-free bullet gun capable of intermittently changing chamber

A caseless bullet and barrel technology, applied in the field of firearms, can solve the problems of easy spontaneous combustion of bullets, high chamber temperature, and fast ablation, and achieve the effects of reducing high temperature and ablation, reducing weapon weight, and saving metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

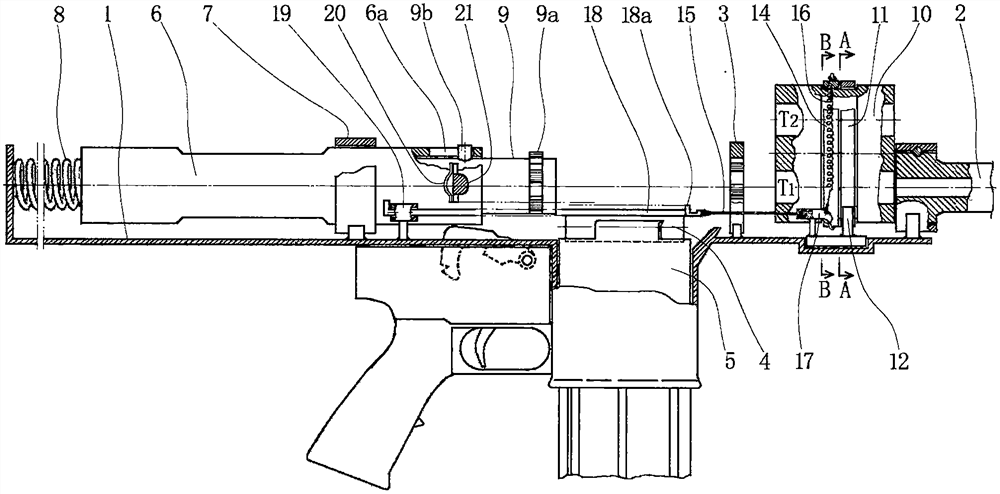

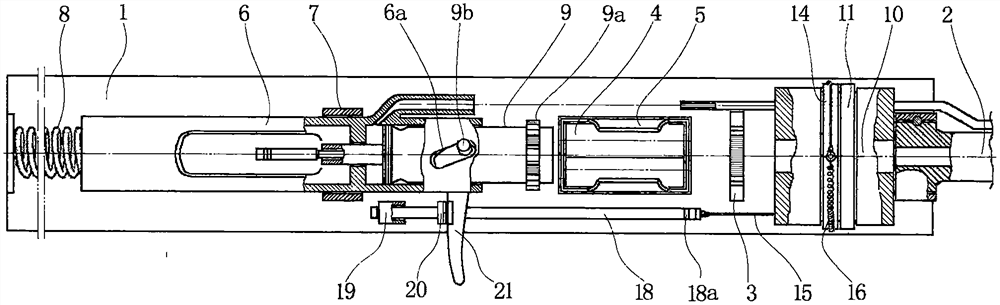

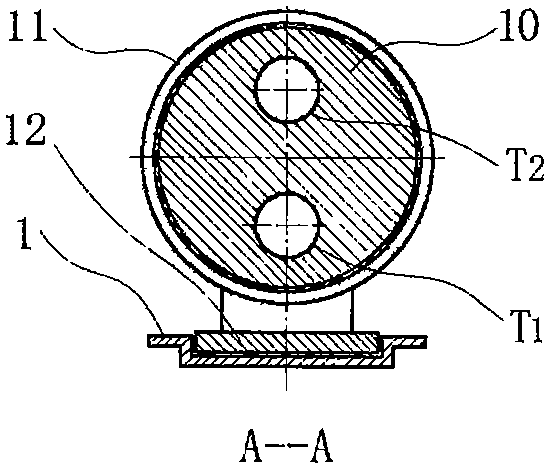

[0018] Such as figure 1 --As shown in 11, a caseless bullet gun with intermittent chamber change, its casing 1 is used to combine various parts, on which the barrel 2, the locking clamp 3 are fixed, and a cylindrical countersunk type non- The magazine 5 of the shell bullet 4 and the machine frame 6 are plugged in a machine frame seat 7 fixed on the casing to move back and forth, and the tail end is touched by a recoil spring 8, and the head end is plugged into a trigger 9 for telescopic sliding , above-mentioned each parts and coordinating relation, working principle all are prior art, and the main feature of this gun is: a cylindrical chamber body 10 is established at the gun barrel tail end, and its axis is positioned at the gun barrel top and is parallel to the gun barrel, It is symmetrically provided with two bullet chambers T1 and T2, which can align the gun barrel alternately with its rotation; Inserted on the socket seat 12 of the casing ( figure 1 , 3 , 6); Establis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com