Self-adaptive angle accurate positioning and clamping device for adjustable blade

A technology with precise angle and clamping device, which is applied in the direction of positioning device, clamping, supporting, etc., can solve the problems of easy deformation of parts, complex blade shape, difficulty in clamping of blade surface, and difficulty in positioning other parts, and achieve reliable pressure. The effect of tight force, fast and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In order to realize the positioning and clamping of the fan blades of the aero-engine, the following embodiments are proposed:

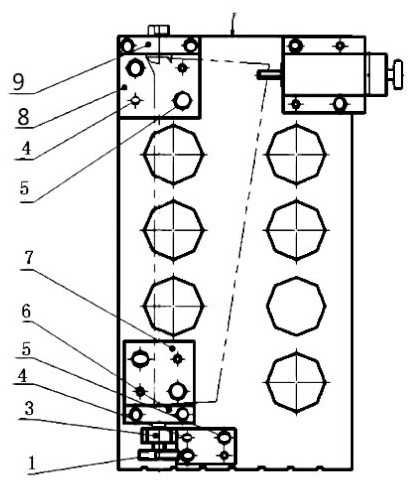

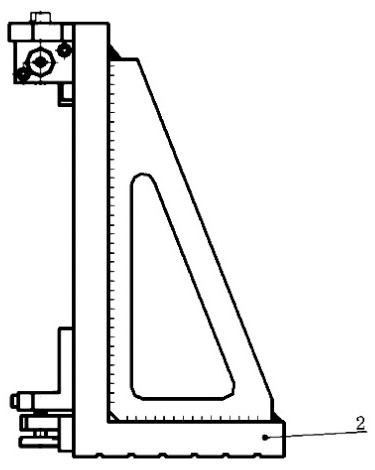

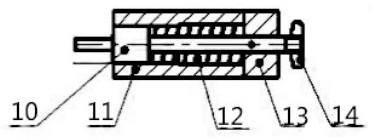

[0034] Such as figure 1 , figure 2 , image 3 with Figure 8 As shown, in this embodiment, an adjustable fan blade self-adaptive angle precise positioning and clamping device is proposed, including a tightening bolt 1, a clamp body 2, a bracket 3, a small end positioning block 7, a large end positioning block 8 and Orienter 11; the clamping bolt 1 is fixed on the lower left side of the clamp body 2 through the interference fit of the positioning pin and the compression screw; the upper end of the clamping bolt 1 is connected to the bracket 3, and the bracket 3 is fixedly arranged on the clamp body 2 Above; the small end positioning block 7 is set on the upper end of the bracket 3 for connecting and fixing one end of the fan blade; the big end positioning block 8 is set on the upper left of the clamp body 2 for connecting and fixing the top...

Embodiment 2

[0055] In order to realize the positioning and clamping of the turboprop blade of the aero-engine, the following embodiments are proposed:

[0056] Such as figure 1 , figure 2 , image 3 with Figure 8 As shown, in this embodiment, an adjustable turboprop blade self-adaptive angle precise positioning clamping device is proposed, including a tightening bolt 1, a clamp body 2, a bracket 3, a small end positioning block 7, and a large end positioning block 8 and an orienter 11; the jacking bolt 1 is fixed on the lower left side of the clamp body 2 through an interference fit of a positioning pin and a compression screw; the upper end of the jacking bolt 1 is connected to a bracket 3, and the bracket 3 is fixedly arranged on the clamp body 2; the small end positioning block 7 is arranged on the upper end of the bracket 3 for connecting and fixing one end of the blade; the large end positioning block 8 is arranged on the upper left of the clamp body 2 for connecting and fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com