Regenerated plastic twin equipment

A technology of recycled plastics and twins, applied in the field of plastic recycling, can solve the problems of unsightly output particles, poor output quality, flat particles, etc., and achieve the effects of small footprint, convenient use and operation, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

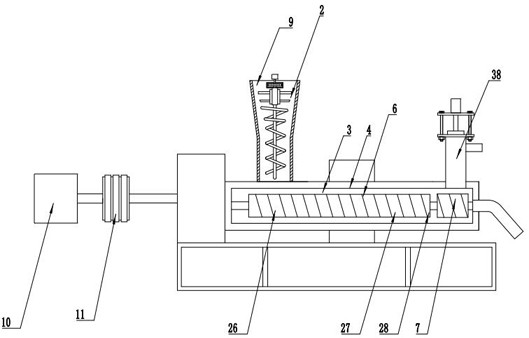

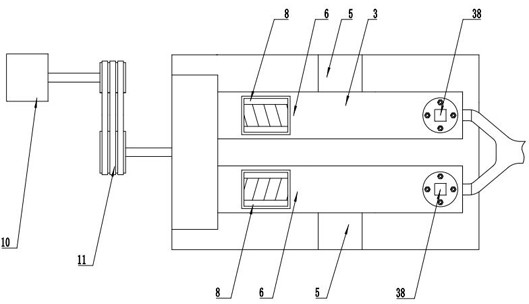

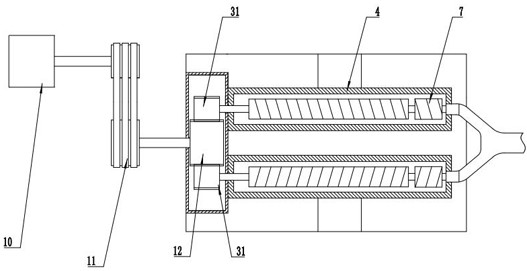

[0030] The present invention relates to a kind of recycled plastic twin equipment. The recycled plastic twin equipment includes a conveyor, a feeder 2 and a forming machine 3. The conveyor continuously transports raw materials to the feeder through a conveyor belt, and the feeder 2 rotates in a circumferential direction. The raw materials are continuously conveyed to the molding machine 3, and the molding machine 3 heats the raw materials and shapes them and discharges them.

[0031] Figure 1 to Figure 8An embodiment of the recycled plastic twin plant of the present invention is shown. A kind of recycled plastic twin equipment, comprising a conveyor, a feeder 2 and a molding machine 3, characterized in that the molding machine 3 includes two left and right adjacent screw barrels 4, and the screw barrels 4 are used for It is connected to the heater for heating the raw material in the screw barrel 4, the screw barrel 4 is provided with a rotating screw 6, and a power device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com