Printed matter online detection and waste rejecting device

A technology for printed matter and receiving device, which is applied to the field of online detection and rejection of printed matter, can solve the problems of reduced production efficiency, easy separation from conveying equipment, less structure of detection equipment, etc., and achieves the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

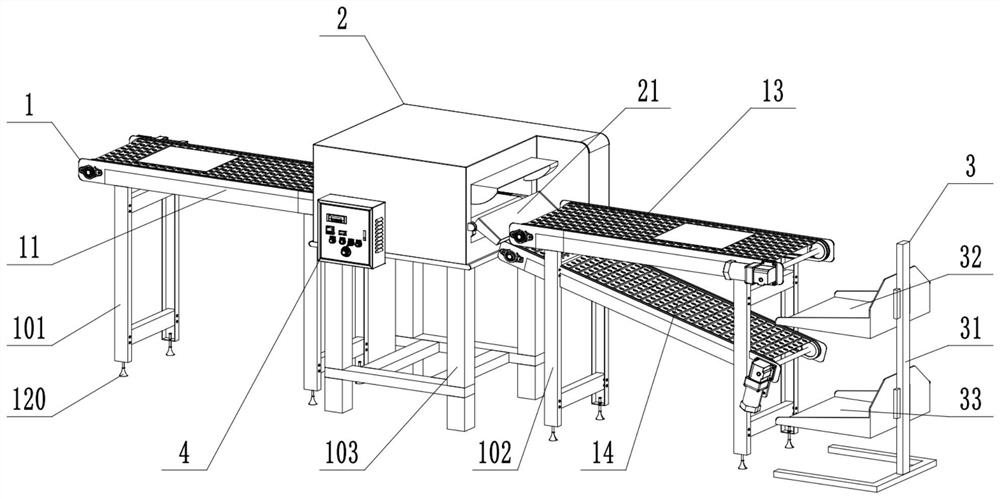

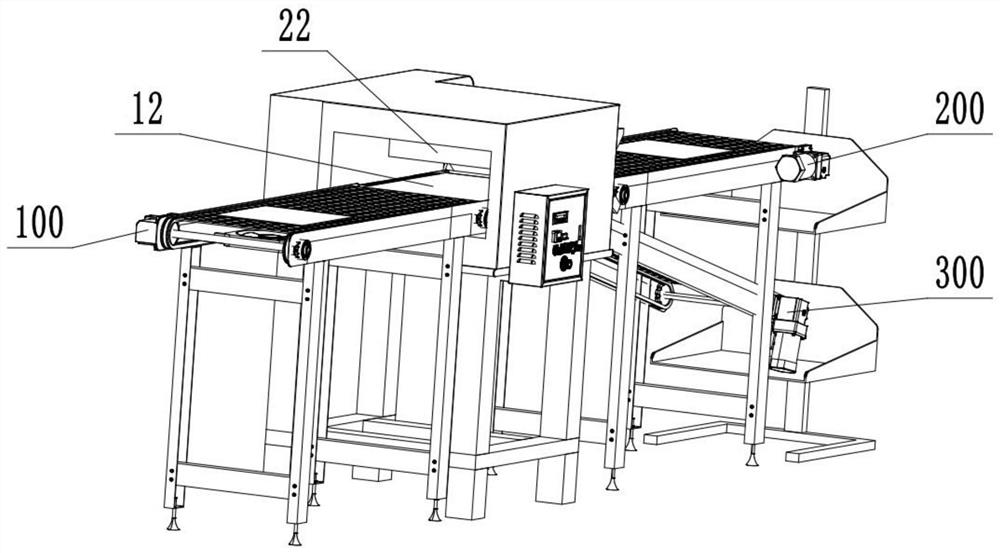

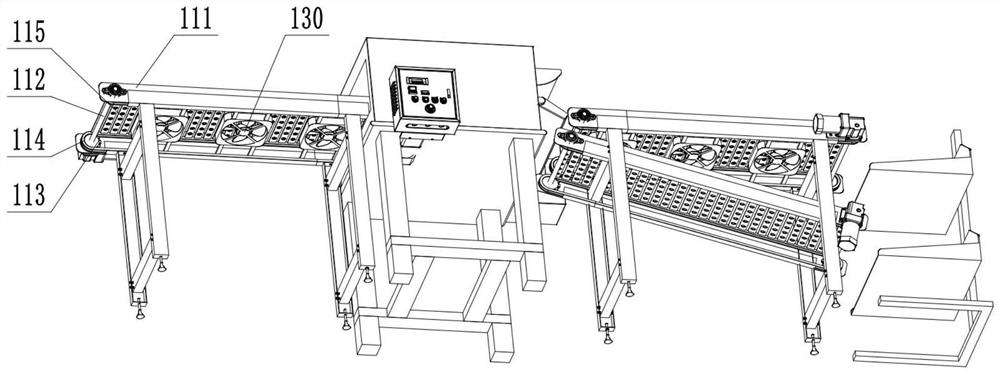

[0023] combined with Figure 1-6 , an online detection and rejecting device for printed matter, including a transmission device 1, a detection and rejection device 2, a receiving device 3, and a control device 4, the transmission device 1 includes an input transmission device 11, a detection transmission device 12, an output transmission device 13, Output transmission device 2 14, one end of the input transmission device 11 is fixedly connected to the detection and rejection device 2, the detection and transmission device 12 is fixedly installed in the detection and rejection device 2, and the detection and rejection device 2 is rotatably installed with a guide plate device 21 , the image recognition device 22 is set in the detection and rejection device 2, the output transmission device one 13 and the output transmission device two 14 are set on the back side of the detection and rejection device 2, and the output transmission device one 13 and the output transmission device t...

Embodiment 2

[0029] The device is installed at the back of the printing equipment. The printed matter that has completed the printing work is transmitted to the detection and rejection equipment through the input transmission equipment. The detection and transmission equipment in the detection and rejection equipment continues to transmit the printed matter and stops at the preset position for detection. The body is equipped with a calculation control circuit board. After the image recognition equipment obtains the graphic information printed on the printed matter, the detection and rejection equipment compares it with the electronic template of the printed matter online to confirm the printing effect, and controls the direction of the guide plate device according to the detection results. Turn over to remove unqualified printed matter; when the test result is qualified, turn over the drive motor to drive the guide plate device to rotate upwards and connect with the output conveying equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com