Wheel rim structure and processing method of rear axle main reducer

A main reducer and wheel rim technology, which is applied in the wheel rim structure and processing field of the rear axle main reducer, can solve the problems of increasing the axial size, thread deformation, increasing the axial size of the original mechanism, etc., to ensure installation accuracy, Prevent vibration loosening and avoid the effect of difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

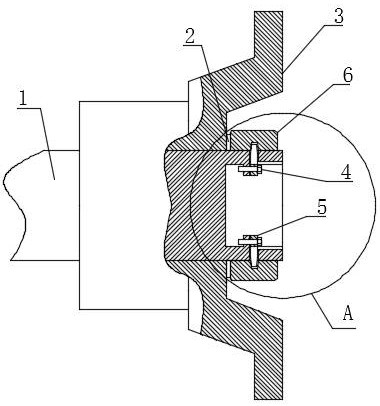

[0021] Example 1: Combining figure 1 As shown, a rear axle main reducer wheel rim structure, the end of the output shaft 1 is installed with a slewing support structure and a connecting flange 3 . The slewing support structure is connected with the vehicle frame to ensure the rotary output of the output shaft 1 .

[0022] The improvements of this embodiment are:

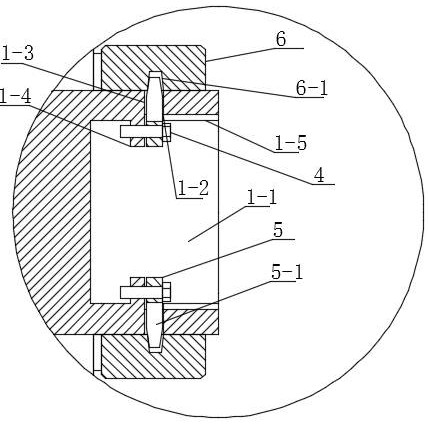

[0023] The end of the output shaft 1 is provided with an external thread, and the fastening nut 6 is threadedly installed on the end of the output shaft 1 to compress the connecting flange 3 on the output shaft 1 . A washer 2 is arranged between the fastening nut 6 and the connecting flange 3 . The inner wall of the fastening nut 6 is provided with an anti-retreat groove 6-1, the cross section is trapezoidal, and the two sides are inclined.

[0024] The shaft center of the end face of the output shaft 1 is provided with a central counterbore 1-1, and the inner wall of the central counterbore 1-1 is provided with a...

Embodiment 2

[0027] Embodiment 2: A method for processing the wheel edge structure of the rear axle final drive, on the basis of the above embodiment 1, combined with figure 2 shown;

[0028] Step 1: Set the connecting flange 3 on the end of the output shaft 1, install the washer 2 and the fastening nut 6, so that the washer 2 and the fastening nut 6 are tightly pressed on the outside of the connecting flange 3.

[0029] Step 2: install the elastic ring 5, place the end of the stop shaft 5-1 on the elastic ring 5 in the guide groove 1-5 and push it inward, and the stop shaft 5-1 slides into the inclined through hole 1-3; When the oblique through hole 1-3 on the output shaft 1 is longer and the anti-retraction shaft 5-1 of the elastic ring 5 is difficult to enter, the elastic ring 5 can be made into two independent parts and installed respectively.

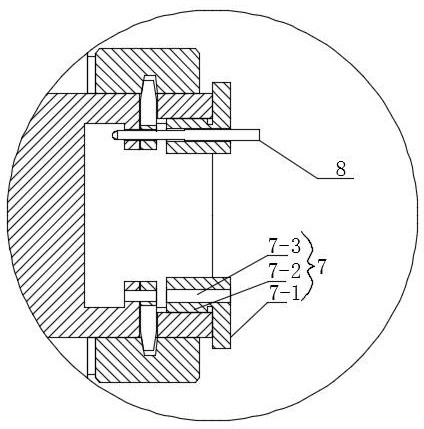

[0030] Step 3: On-site drilling on the elastic ring 5 and the block 1-4; the guide sleeve 7 is annular, the outer end surface of the guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com