All-plastic emulsion pump head

A lotion pump and plastic technology, applied in packaging, individual handheld devices, closures, etc., can solve the problems of metal spring and metal ball corrosion, content contamination, etc., to avoid vibration loosening, easy recycling, self-locking structure Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

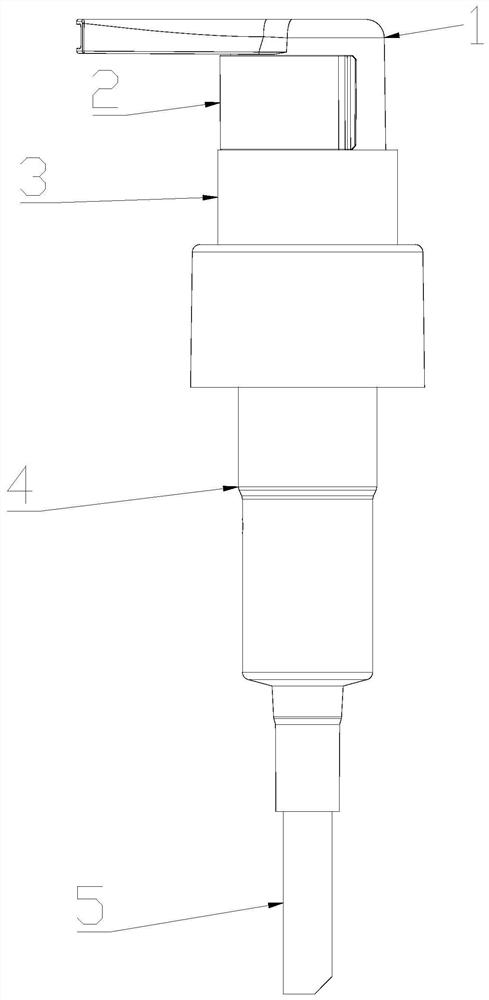

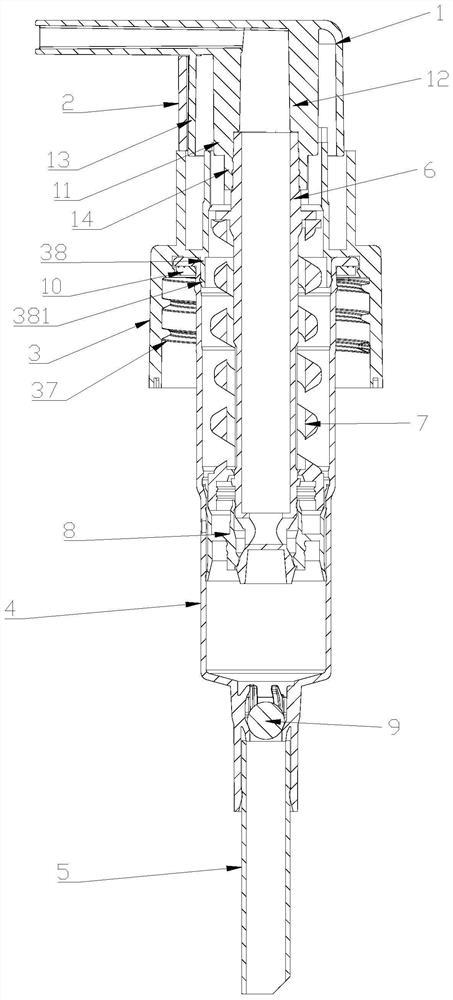

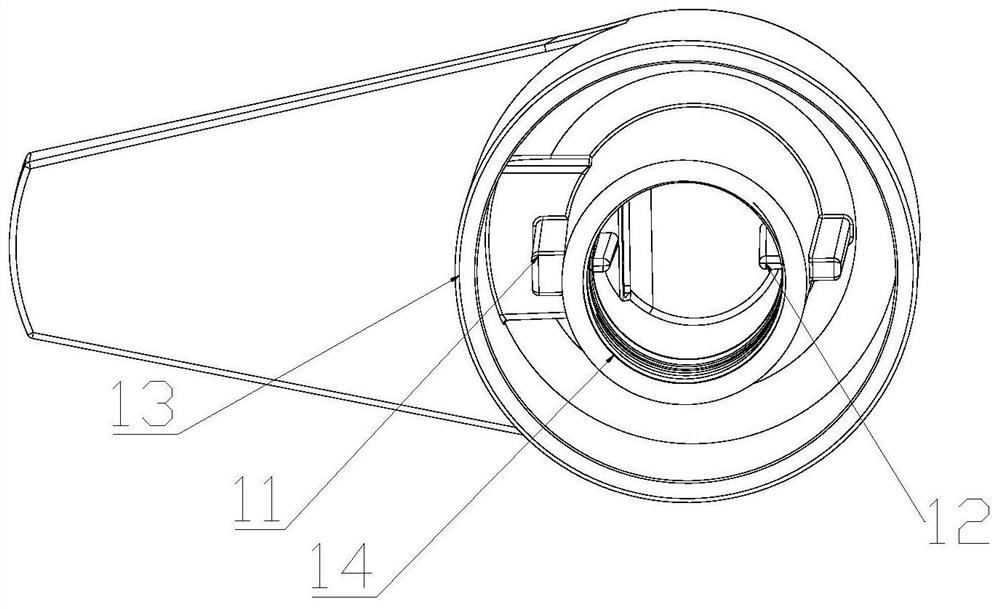

[0028] see Figure 1-8 As shown, the present invention relates to an all-plastic lotion pump head, including a press head 1, a main column 6, a pump body 4, a bottle cap 3, a plastic spring 7, and a movable pump plug 8, wherein the press head 1, the main column 6, the pump Body 4, bottle cap 3, plastic spring 7, and movable pump plug 8 are all made of plastic; the upper end of the bottle cap 3 is sleeved on the top of the pump body 4; The lower end of the main column 6 extends into the pump body 4 through the lock cover, and the main column 6 can move along the axial direction of the lock cover; the movable pump plug 8 is sleeved on the outer surface of the lower end of the main column 6, And the outer surface of the movable pump plug 8 is movably connected with the inner surface of the pump body 4; wherein the outer wall of the upper end of the main column 6 is provided with a circle of annular flange 61 positioned at the lower end of the press head 1, and the outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com