Submersible full-through-flow gate pump with front guiding vane with adjustable placing angle

An adjustable technology with front guide vanes, which is applied in the direction of cross-flow pumps, circulation pumps, pumping devices for elastic fluids, etc., and can solve the problem of difficult to achieve accurate flow adjustment and single working conditions of full-through-flow gate pumps, etc. problems, to achieve the effect of reducing water evaporation loss, reducing water pollution from multiple sources, and achieving significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

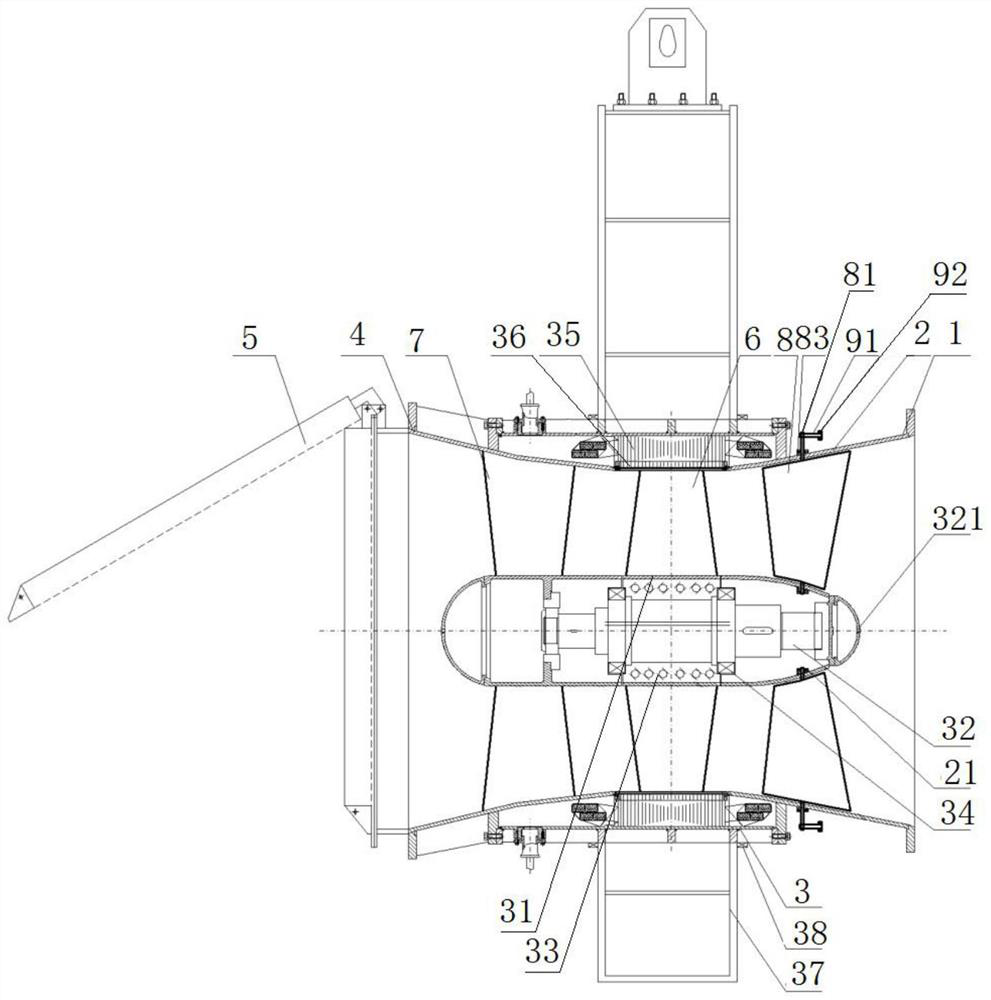

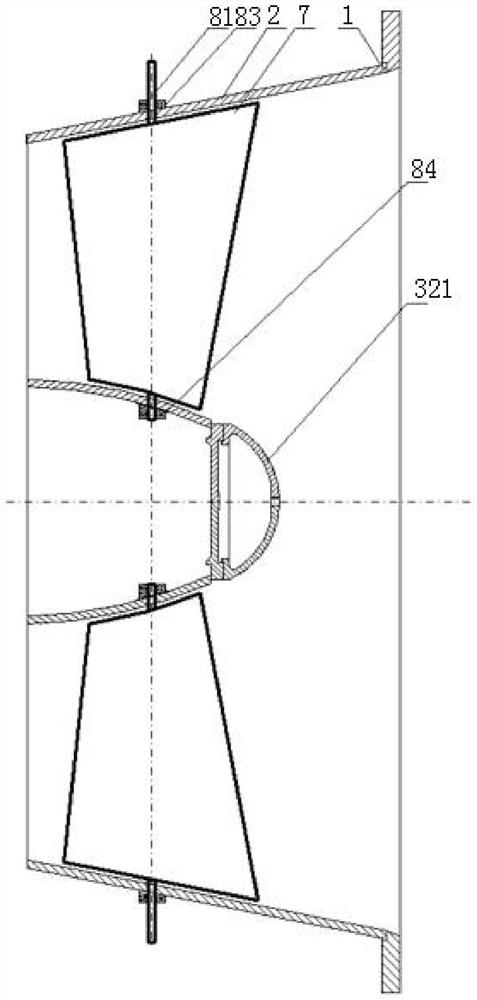

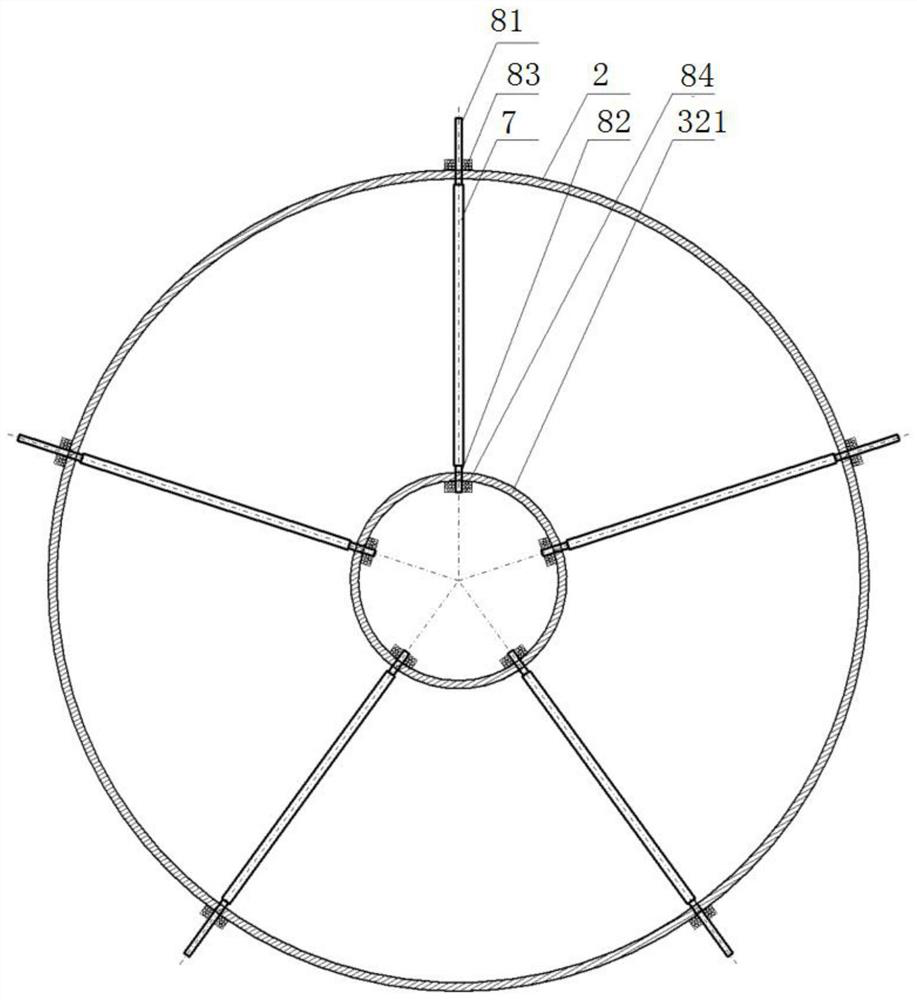

[0029] Referring to the accompanying drawings, we can see that: figure 1 As shown, the submersible full-through flow gate pump with adjustable front guide vanes, from the water inlet to the outlet, includes water inlet bell mouth 1, front guide vane body 2, pump casing 3, and rear guide vane body 4 And flap door 5; There is an impeller hub 31 in the front guide vane body 2, the pump casing 3 and the rear guide vane body 4; a stator 36 is arranged in the pump casing 3, and a rotor 35 is arranged in the stator 36;

[0030] One end of the impeller 6 is welded to the inner cavity of the rotor 35, and the other end is connected to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com