Floating valve control method for vertical evaporative humidifier for preventing water leakage

A control method and anti-leakage technology, applied in control input related to air characteristics, air humidification system, heating and ventilation control system, etc., can solve problems such as abnormal float valve and water leakage, and achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

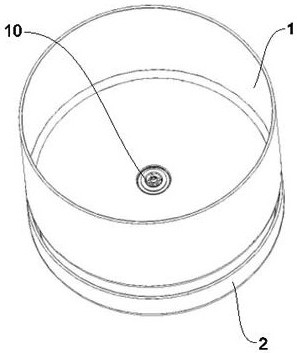

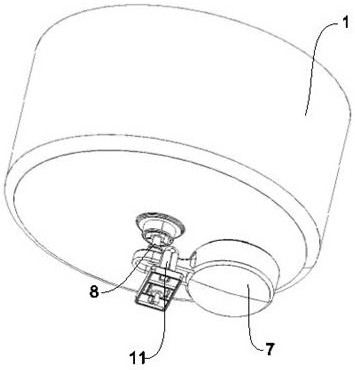

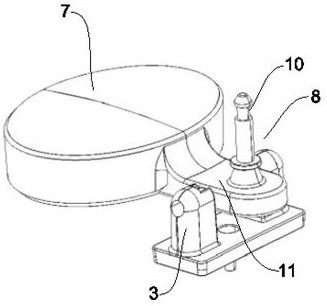

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0023] An embodiment of the present invention is a method for controlling a float valve of a vertical evaporative humidifier for water leakage prevention, the method includes the following steps.

[0024] Step S11, the sensor module collects the water level value in the evaporation water tank, and transmits it to the main control module.

[0025] Step S12 , the main control module compares the current water level with the preset threshold, and judges whether it is greater than the preset threshold.

[0026] Step S121, when the judgment result is yes, the main control module controls the output end of the driving motor to lift the valve stem, and the valve stem forms a limit on the float end of the float valve. At this time, the float end cannot fall down, so that the float valve The sealing plug on the adjustment end of the water storage tank is kept sealed at the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com