Three-way fatigue test device for steel wire rope vibration isolator

A technology of fatigue test and vibration isolator, which is applied in the direction of measuring device, vibration test, machine/structural component test, etc. It can solve the problems of failure to meet customer product reliability, lack of fatigue test equipment, and failure to meet the needs of manufacturers for fatigue testing and other problems, to achieve the effect of saving maintenance, reducing costs, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

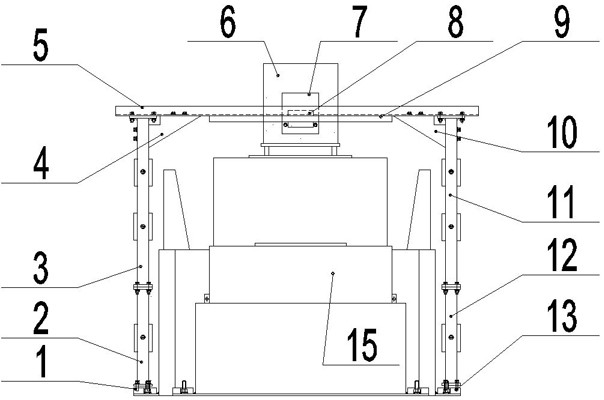

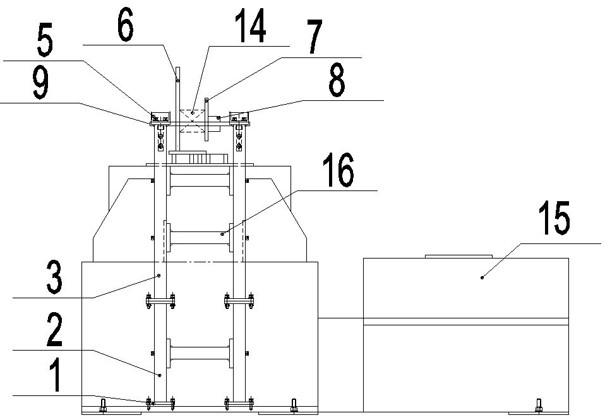

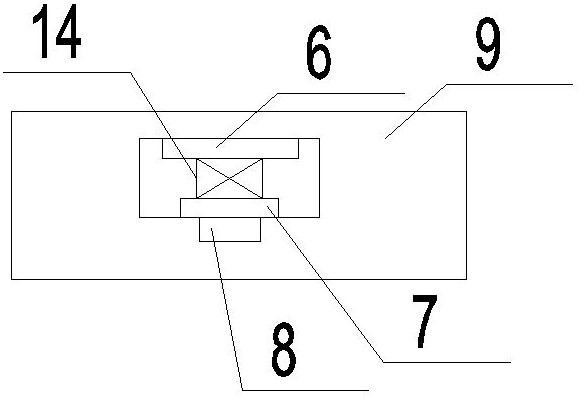

[0019] The present invention provides a technical solution, according to Figure 1-3 As shown, a three-way fatigue test device for a steel wire rope vibration isolator, the device includes a first connecting base plate 1, the upper sides of the front and rear ends of the first connecting base plate 1 are respectively vertically fixed with first support rods 2, and the two The upper ends of the first support rods 2 are vertically fixed with a second support rod 3, and the device also includes a second connection substrate 13, which is arranged in parallel with the first connection substrate 1, and the second connection substrate 13 is arranged in parallel with the first connection substrate 1. The upper sides of the front and rear ends of the connecting base plate 13 are respectively vertically fixed with a fourth support rod 12, and the upper ends of the two fourth support rods 12 are vertically fixed with a third support rod 11, and the second support rod 3 and The upper ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com