Bolt tightness intelligent detection piece

An intelligent detection and bolt technology, applied in the direction of measuring torque/torsional force, measuring device, testing of mechanical parts, etc. during tightening, can solve the problems of not having the ability to monitor the looseness of bolts, so as to ensure effectiveness, safety and reliable detection , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

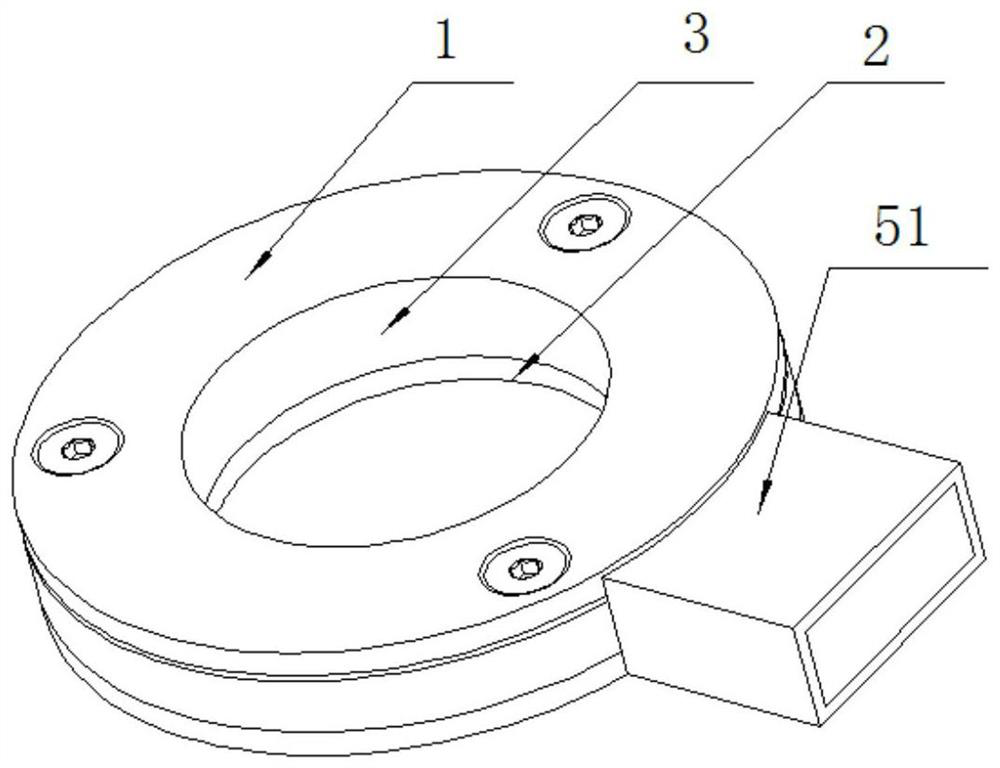

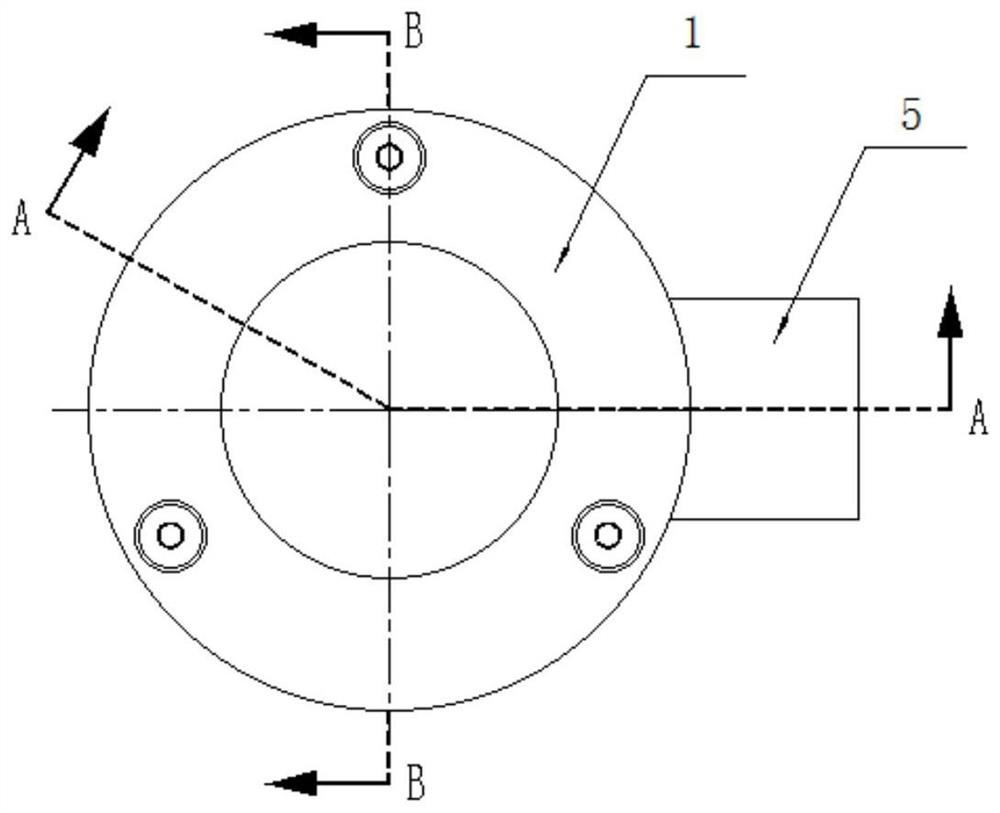

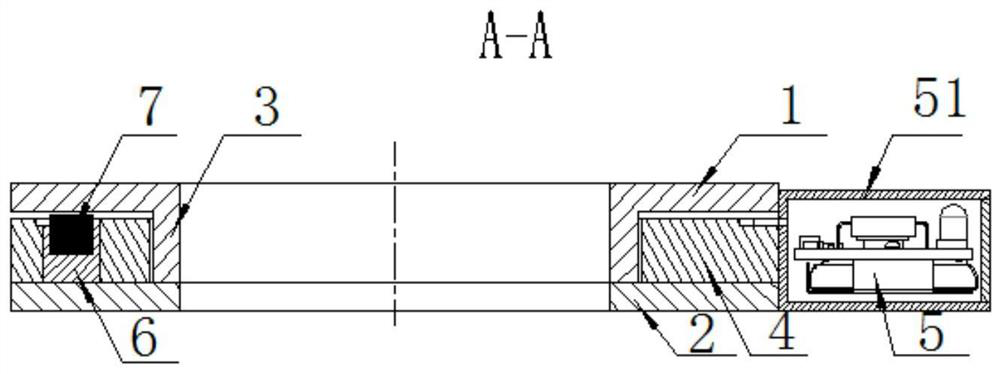

[0031] Such as Figure 1 ~ Figure 4 The bolt tightness intelligent detection part shown is composed of a first pressure-bearing part 1, a second pressure-bearing part 2, a support part 3, a detection base 4, several contact detection switch parts S and an alarm device 5 and other components. Wherein the first pressure-bearing part 1 and the second pressure-bearing part 2 are annular structures with bolt holes of the same size in the center, and the first pressure-bearing part 1 and the support part 3 are integrally structured, the first pressure-bearing part Part 1 and the second pressure-bearing part 2 are arranged facing each other, especially the bolt holes on the first pressure-bearing part 1 and the second pressure-bearing part 2 are facing each other, the first pressure-bearing part 1 and the second pressure-bearing part 2 After being installed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com