Glass heat insulation and sound insulation performance test box and test method thereof

A heat and sound insulation and test box technology, which is applied in the thermal development of materials and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of glass display devices such as single display function, unintuitive contrast effect, and increased detection cost, and achieve improvement. Test efficiency, ease of popularization and application, and the effect of reducing testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

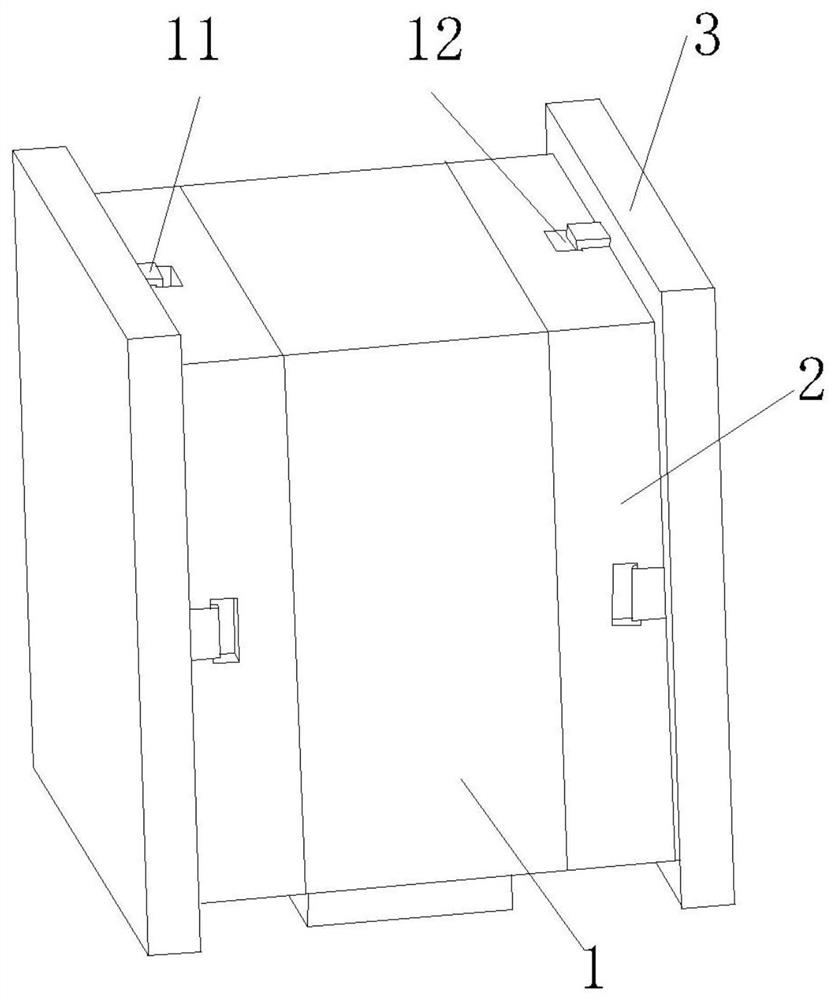

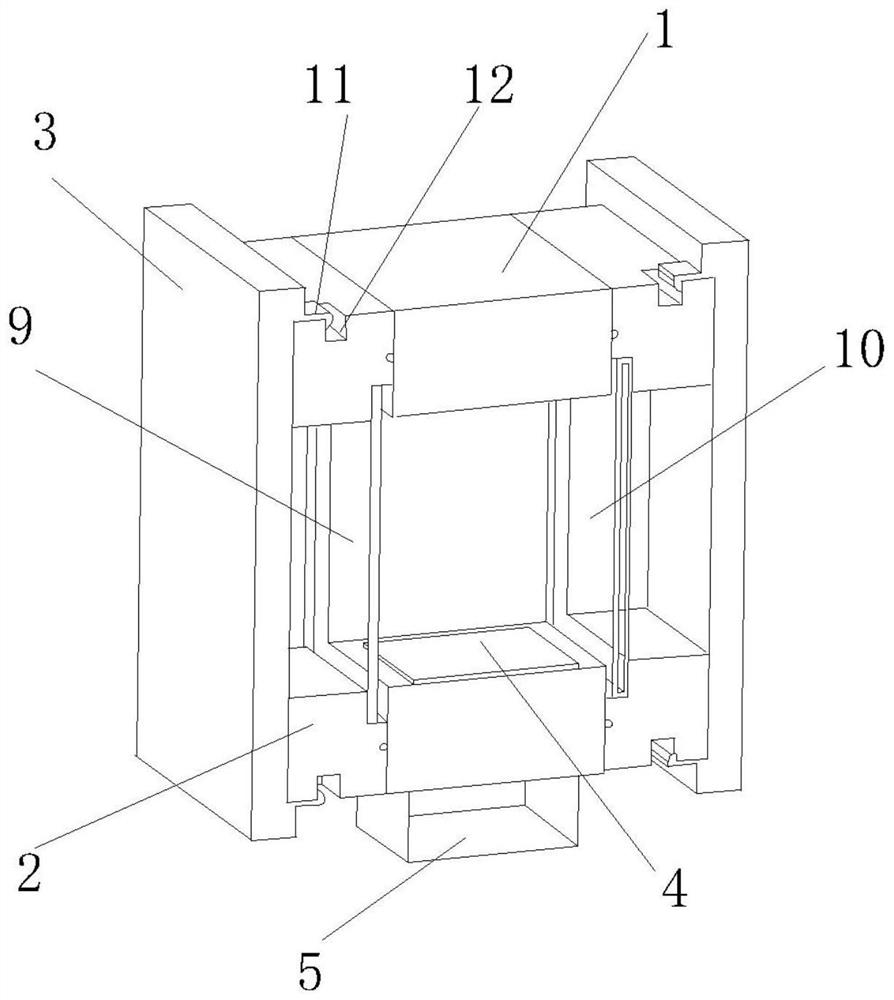

[0036] Such as Figure 1-Figure 2 As shown, a glass heat and sound insulation performance test box includes a box body 1 , a glass frame 2 and a cover plate 3 .

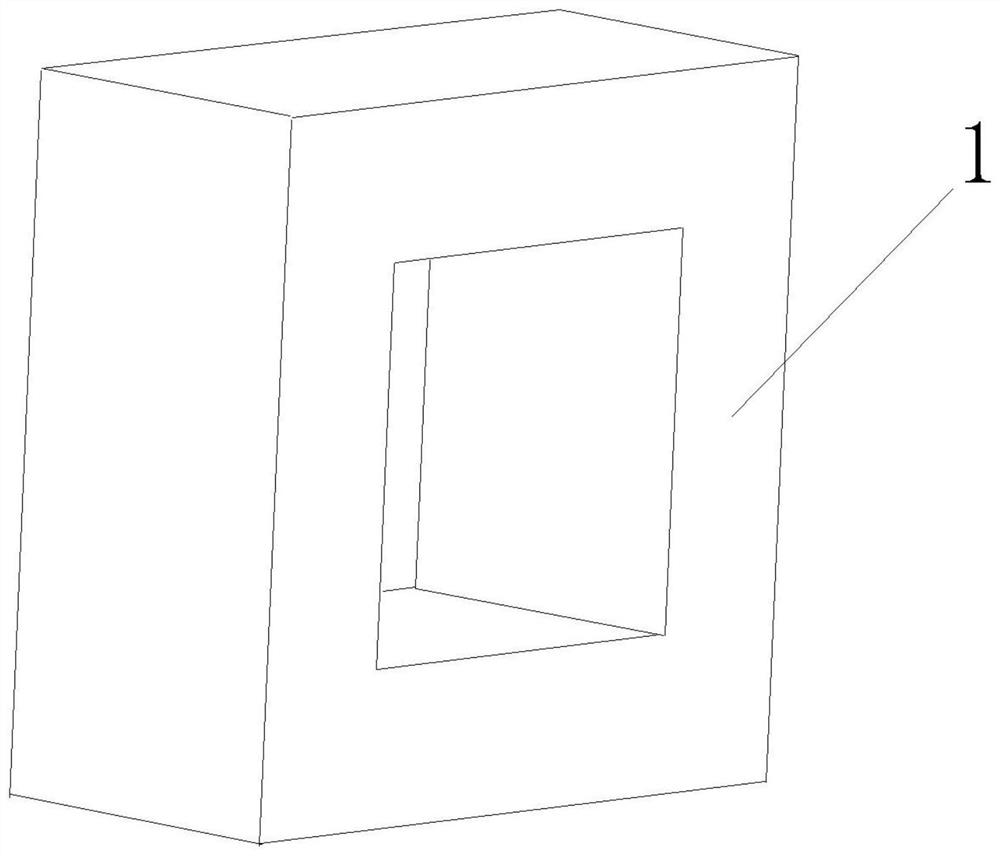

[0037] Box 1, such as Figure 1-Figure 6 As shown, it is made of superstructure material. There is a through inner cavity between the two sides of the box body 1. The bottom of the inner cavity is provided with a heating plate 4. A noise source is suspended in the inner cavity. The noise source is suspended on the top of the inner cavity or The middle position; the outer side of the bottom of the box body 1 is provided with a cover plate 5, and the inside of the cover plate 5 is equipped with a relay, a temperature control circuit and an external noise source interface, wherein the cover plate 5 is only used for enclosure protection. Its size needs to be designed according to the actual electrical requirements.

[0038] In this embodiment, the noise source is a speaker, which can withstand a temperature below 80°C....

Embodiment 2

[0046] Such as Figure 1-Figure 4 As shown, compared with Embodiment 1, the glass frame 2 of this embodiment is provided with a mounting groove 8 on the side of the glass mounting groove 6 corresponding to the side of the box body 1 having an inner cavity, and the mounting groove 8 is used for mounting Hinge or hinge, the two glass frames 2 are respectively installed on the corresponding sides of the box body 1 through hinges or hinges, when replacing the glass to be tested, the glass frame 2 only needs to be rotated around the hinge 2 Unfold (refer to the structure of the door), which is convenient for frequent replacement of the glass to be tested.

[0047] Other components and principles of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0049] Such as Figure 1-Figure 5 As shown, compared with Embodiment 1, one side of the cover plate 3 of this embodiment is provided with a cover groove matching the glass frame 2, and the side of the glass frame 2 opposite to the glass installation groove 6 can be completely embedded in the cover. in the slot.

[0050] The notch edge of the cover groove is provided with an L-shaped block 11 in the middle, one side of the block 11 is fixed on the cover plate 3, and the other side of the block 11 is arranged towards the cover groove, and the block 11 is made of elastic material. The side of the glass frame 2 is provided with a locking groove 12 , and when the glass frame 2 is embedded in the cover groove, the locking block 11 can be just locked in the locking groove 12 .

[0051] During installation, remove the block 11, cover the cover plate 3 on the glass frame 2 to be covered, put down the block 11, and the block 11 will be stuck in the slot 12 of the box body 1, and the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap