Linear motor primary and traction linear motor

A linear motor, primary technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor heat dissipation, small heat dissipation, poor heat dissipation, etc., to increase residence time, improve heat dissipation capacity, reduce The effect of the component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

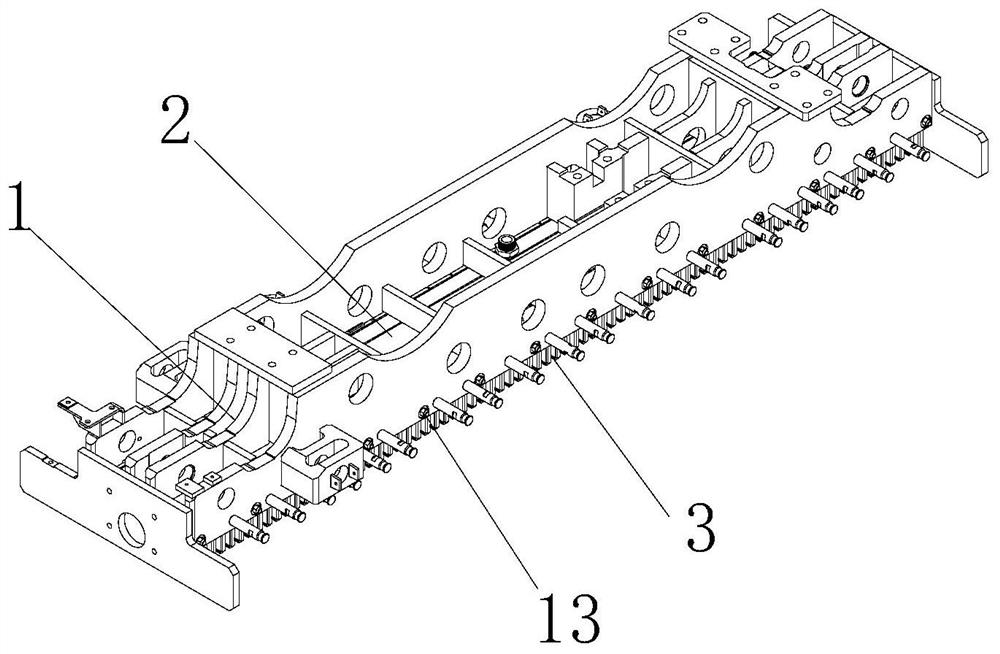

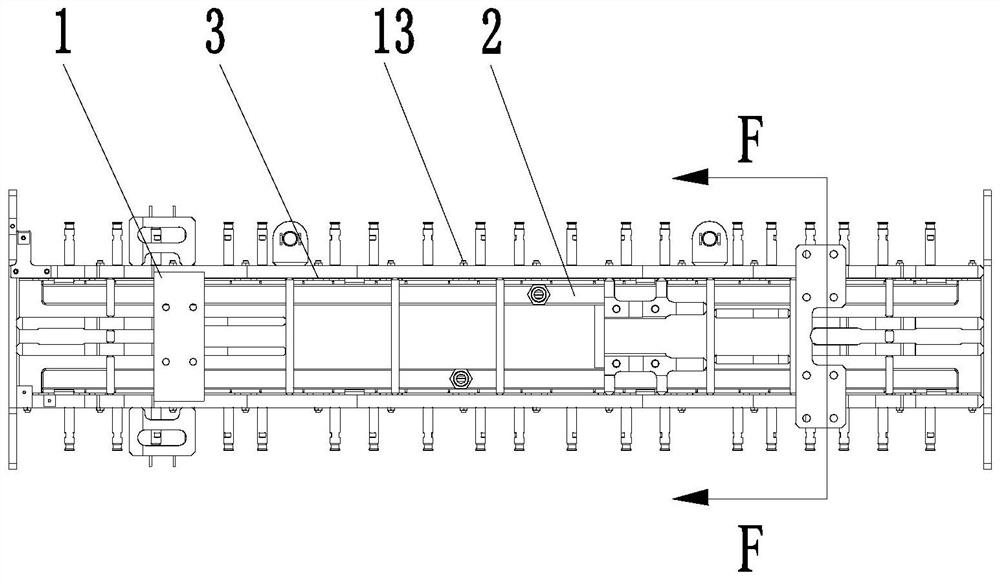

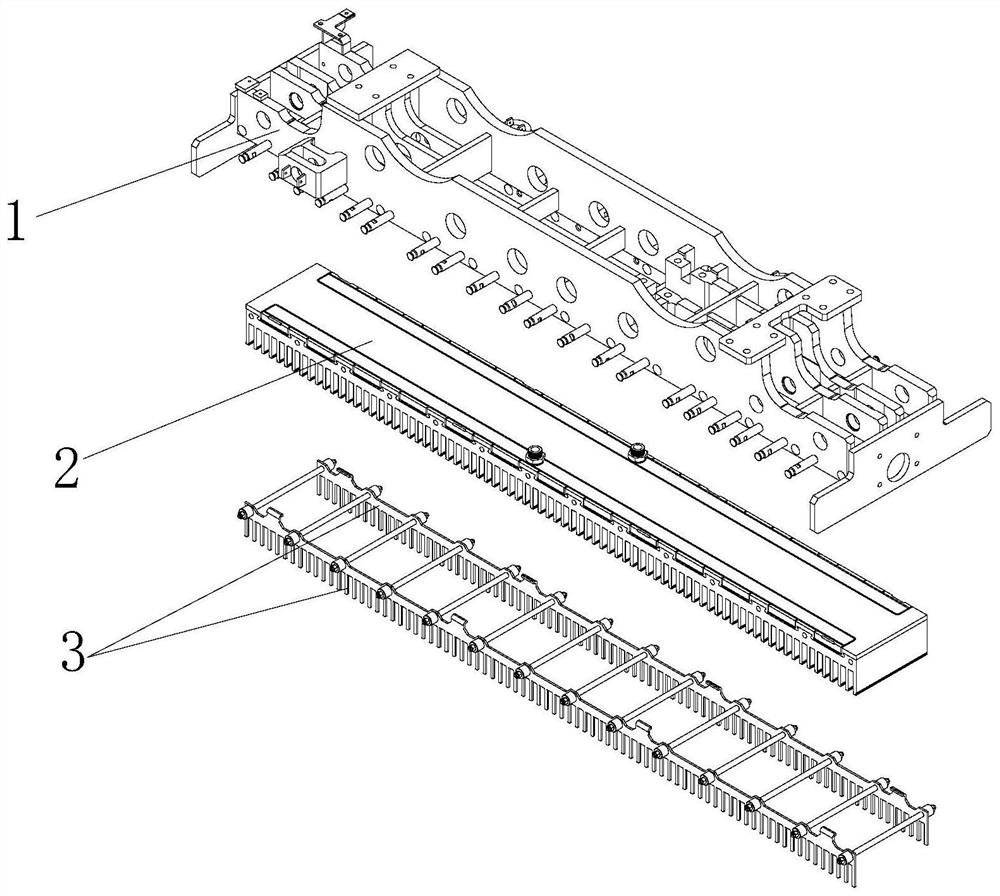

[0053] Figure 1 to Figure 3 An embodiment of the primary stage of the linear motor of the present invention is shown, wherein the primary stage of the linear motor includes a base 1, an iron core assembly 2, and a tooth pressure plate 3, and the iron core assembly 2 includes a radiator 4 and an iron core 5, and the radiator 4 is longitudinally along the iron core 5 Set on the upper surface of the iron core 5, the radiator 4 is provided with a fluid inlet 41 and a fluid outlet 42, the fluid inlet 41 is located in the middle of the radiator 4, and the radiator 4 is provided with a plurality of cross-hole groups 43 and used to connect the cross-through The hole group 43 is a longitudinal channel 44 communicating with the fluid inlet 41 and the fluid outlet 42 . The iron core assembly 2 is clamped from both sides by two tooth pressure plates 3 and installed in the machine base 1 .

[0054] When the linear motor is in primary operation, the radiator 4 is started, and the heat diss...

Embodiment 2

[0074] The linear motor primary of this embodiment is basically the same as that of Embodiment 1, the only difference is that, as Figure 19 As shown, the cross-sections of the block and the slot in this embodiment are not dovetail-shaped, but trapezoidal, and the angle between the two hypotenuses of the trapezoid is α, so that the formed block and slot are regular in shape and easy to process.

[0075] Of course, in other embodiments, it may also be in other shapes, such as a rectangle.

[0076] This embodiment also provides a traction linear motor, which includes the linear motor primary of this embodiment. Since the traction linear motor includes the primary linear motor of this embodiment, it also has the advantages of the primary linear motor described above.

Embodiment 3

[0078] The linear motor primary of this embodiment is basically the same as that of Embodiment 1, the only difference is that, as Figure 20 As shown, the lengths of the chamfer 10 on the radiator 4 and the folded edge 11 on the tooth pressure plate 3 of this embodiment are consistent with the length of the tooth pressure plate 3, and this setting can better prevent the core assembly 2 from vertically The above displacement enhances the overall strength of the core assembly 2.

[0079] This embodiment also provides a traction linear motor, which includes the linear motor primary of this embodiment. Since the traction linear motor includes the primary linear motor of this embodiment, it also has the advantages of the primary linear motor described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com