Cattle feed manufacturing method for cattle farm and processing and forming device

A production method and processing and molding technology, which are used in the molding or processing of animal feed, feed, food processing, etc., can solve the problems of easy leakage to the ground, unfavorable environmental cleanliness, and inability to prevent cattle diseases, so as to improve quality and improve Immunity, reducing the effect of drug use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

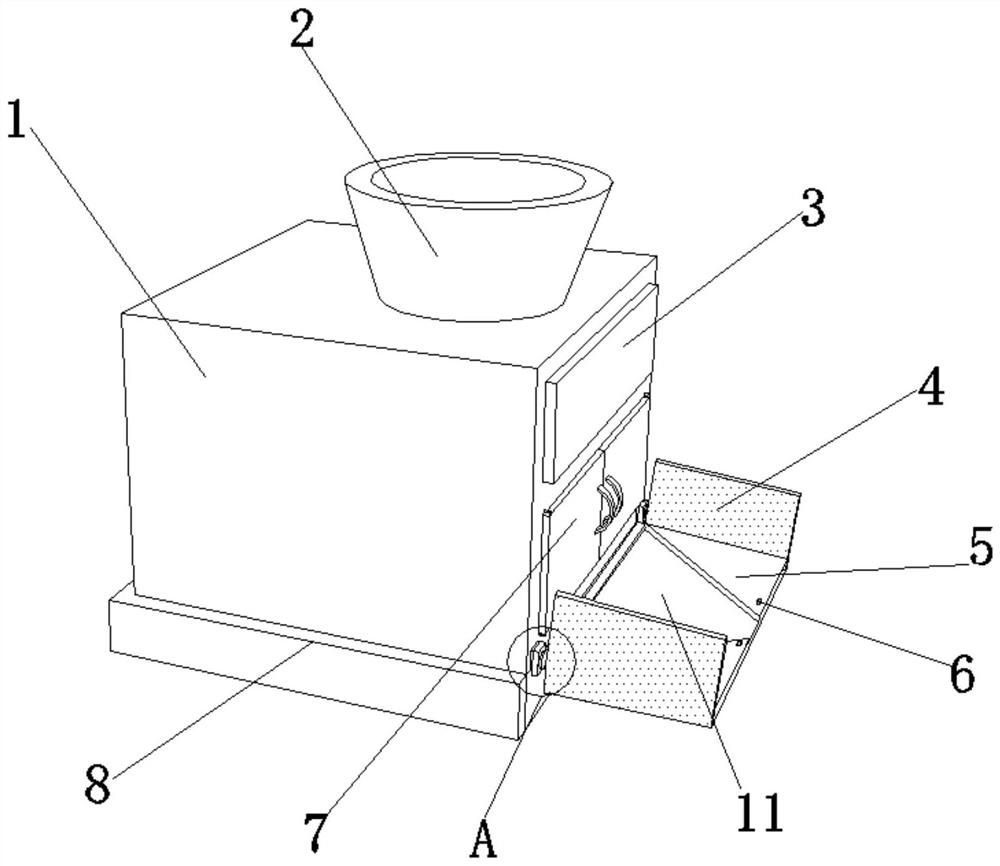

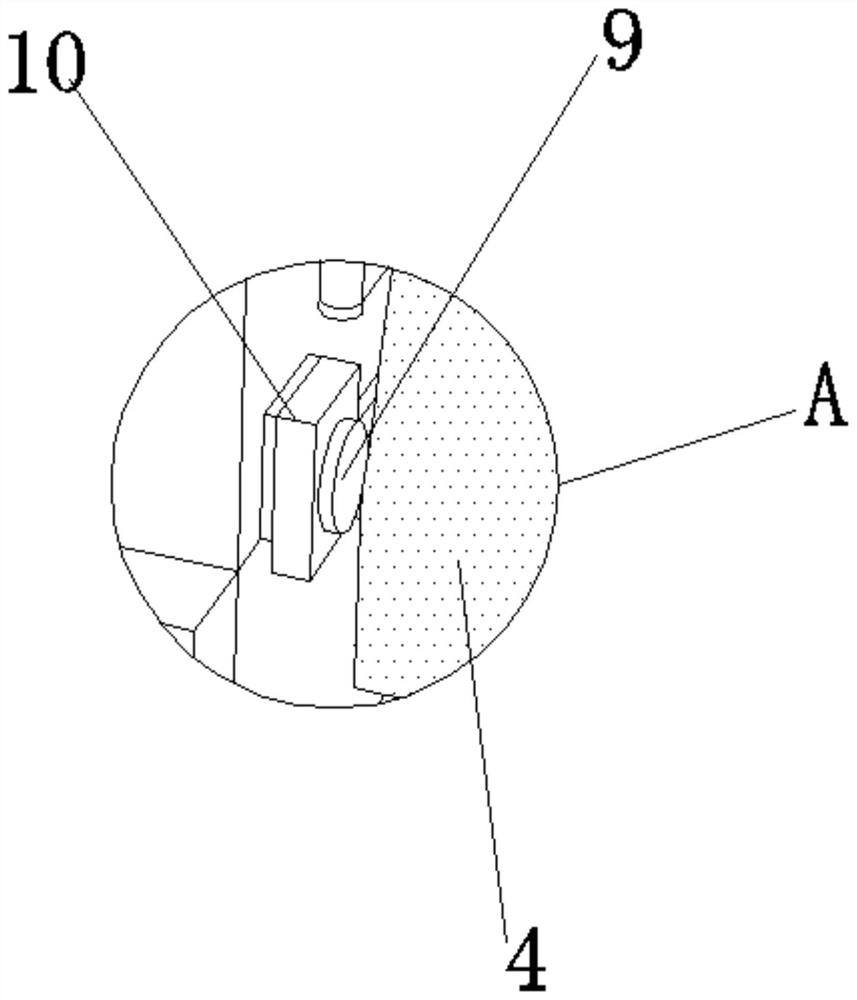

[0030] A cattle feed production method and a processing and forming device for a cattle farm, comprising a device body 1, a base 8 is provided at the bottom of the device body 1, a feeding port 2 is provided at the top of the device body 1, and a side surface of the device body 1 is provided with Observation window 3, the bottom of observation window 3 is provided with discharging door 7, and the bottom of device body 1 is threadedly connected with fixed screw rod 9 and installation steel plate 10 through the threaded hole that offers, and the outer surface of installation steel plate 10 is welded with inclined plate 5, inclined The left and right sides of the plate 5 are welded with two side baffles 4; the surface of the inclined plate 5 is provided with a guide groove 11; , the outside of the material bag hanging needle 6 is articulated with a charging bag, and the discharged feed can directly fall into the inside of the packaging bag at the bottom of the material guide groov...

Embodiment 2

[0041] A cattle feed production method and a processing and forming device for a cattle farm, comprising a device body 1, a base 8 is provided at the bottom of the device body 1, a feeding port 2 is provided at the top of the device body 1, and a side surface of the device body 1 is provided with Observation window 3, the bottom of observation window 3 is provided with discharging door 7, and the bottom of device body 1 is threadedly connected with fixed screw rod 9 and installation steel plate 10 through the threaded hole that offers, and the outer surface of installation steel plate 10 is welded with inclined plate 5, inclined The left and right sides of the plate 5 are welded with two side baffles 4; the surface of the inclined plate 5 is provided with a guide groove 11; , the outside of the material bag hanging needle 6 is articulated with a charging bag, and the discharged feed can directly fall into the inside of the packaging bag at the bottom of the material guide groov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap