Assembling device and method for ball cage coupling hoop

A technology for assembly devices and couplings, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency and high labor intensity, and achieve high labor intensity, low work efficiency, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

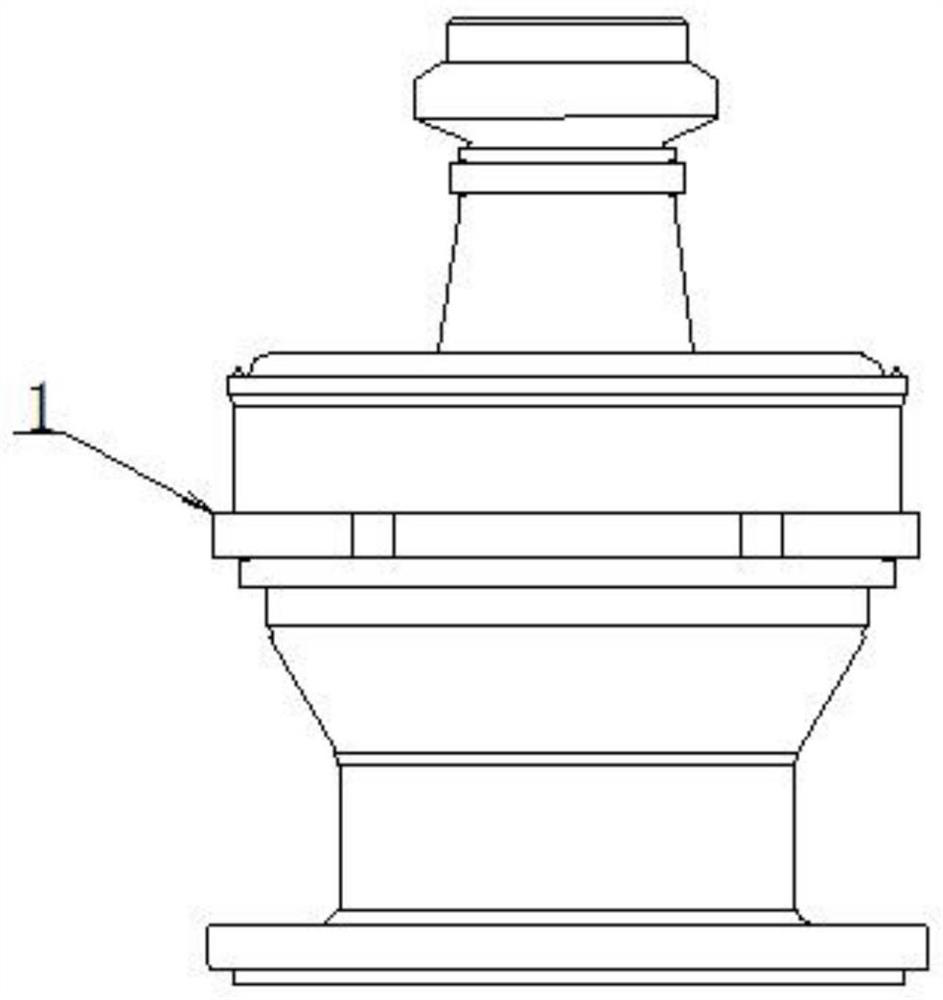

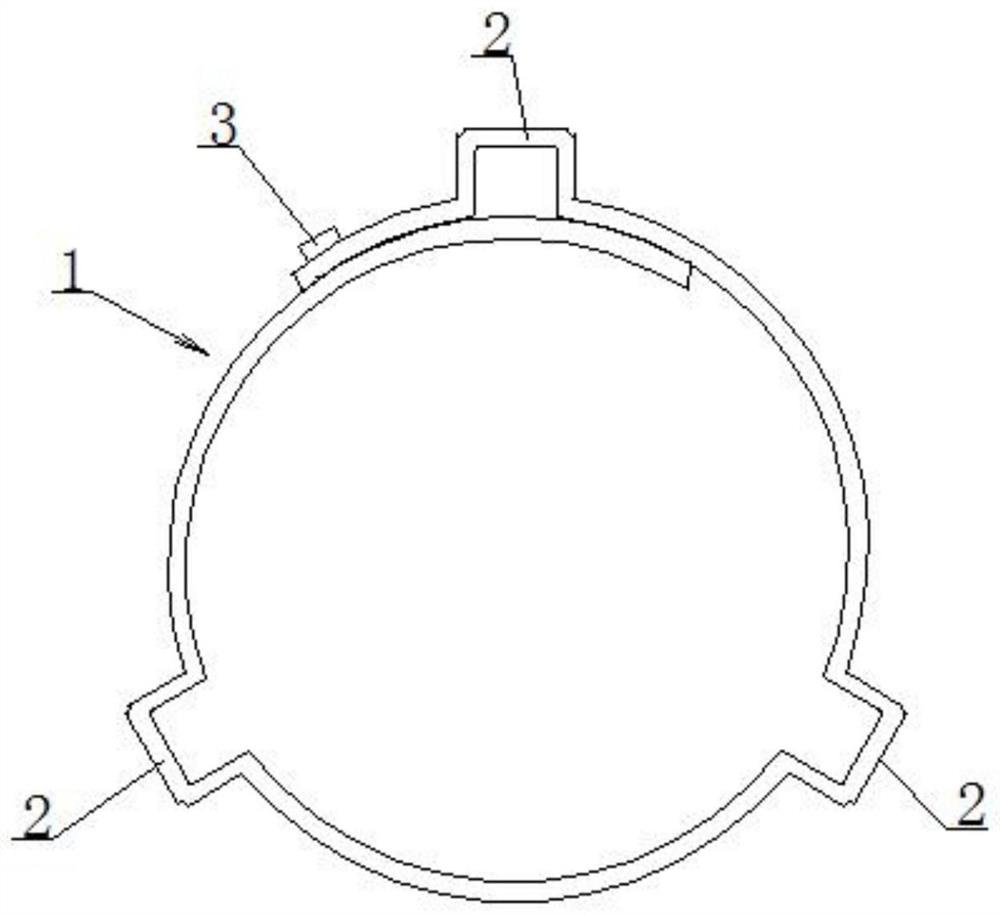

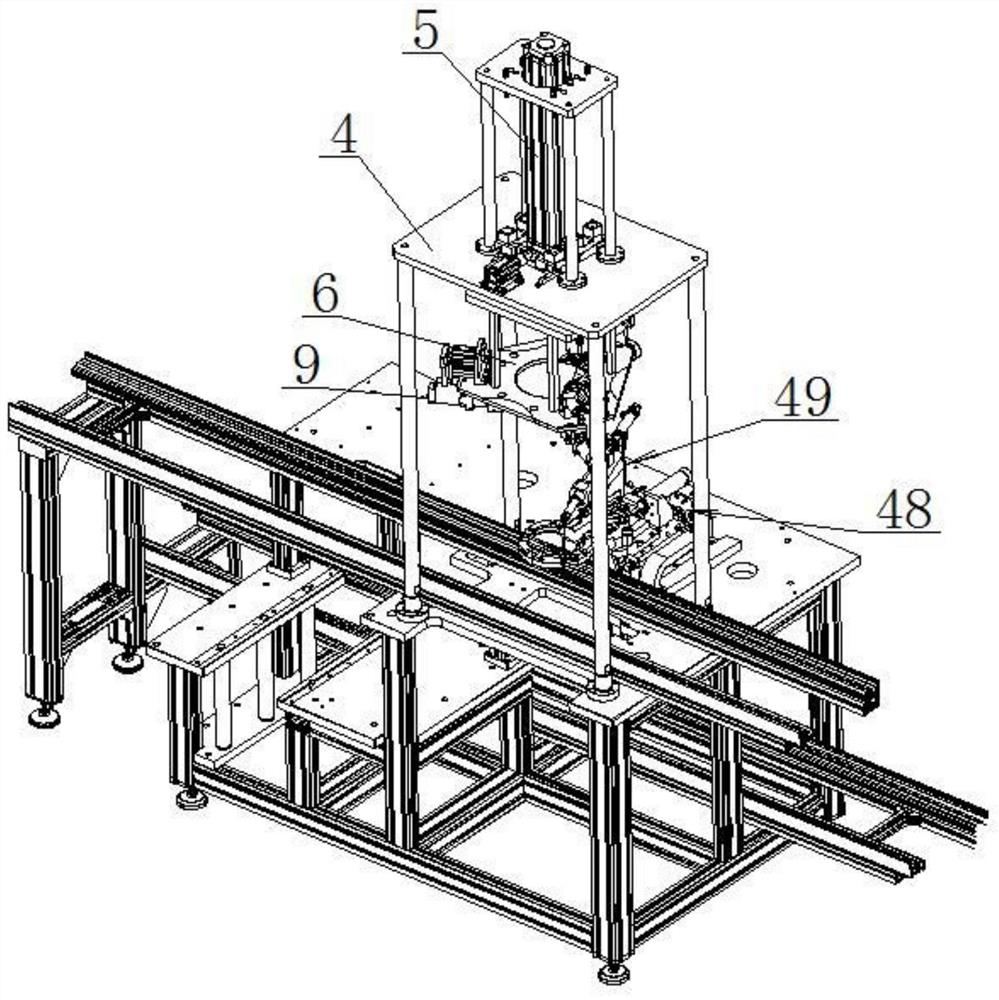

[0041] The assembly device of the ball cage coupling clamp includes a frame 4, a positioner 48, a compactor 49, a pneumatic clamp 9, a lifting cylinder 5 and an assembly plate 6 (see the appendix image 3 with 4 ).

[0042] The top of the frame 4 is equipped with an assembly plate 6 through a lifting cylinder 5 (see the attached image 3 with 4 ); the center of the assembly plate 6 is provided with an avoidance hole 47 (see the attached manual Figure 13 ). The lifting cylinder 5 can drive the mounting plate 6 to move up and down during work.

[0043] The bottom end of the assembly plate 6 is evenly installed with three sets of slide seats 7 through the push cylinder 8 and the guide rail; the three sets of slide seats 7 are radially arranged, and the push cylinder 8 can drive the corresponding slide seat 7 to move back and forth toward the center of the assembly plate 6 when the push cylinder 8 is working .

[0044] Pneumatic clamp 9 is housed on the sliding seat 7 (refe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap