Protective cover of machine tool guide rail sliding block

A technology of guide rail slider and protective cover, which is applied to maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc. Disassembly, easy operation, to achieve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

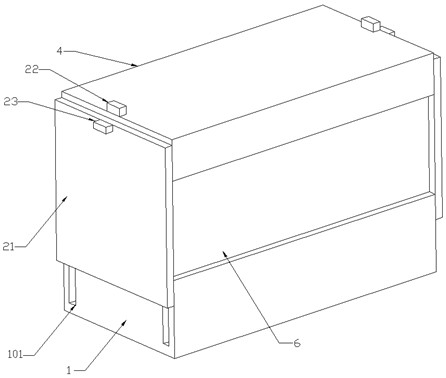

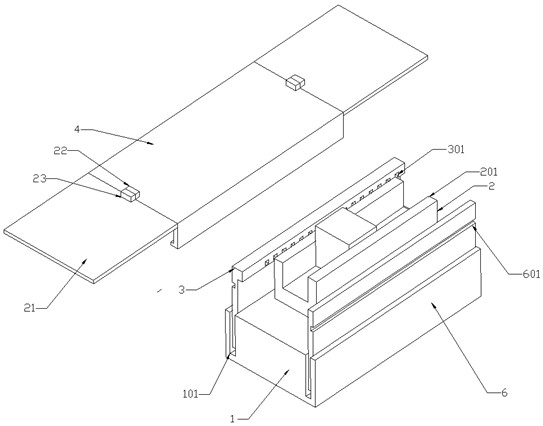

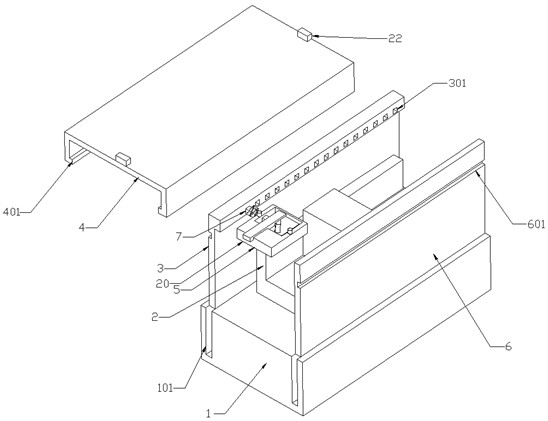

[0021] to combine Figure 1 to Figure 5 As shown, a protective cover of a machine tool guide rail slider includes a machine tool guide rail slider body 2 and a protective cover, and also includes a heat dissipation assembly 13 and a drive mechanism 19; the protective cover includes side plates I3, side plates II6 and U-shaped covers 4; Side plate Ⅰ3 and side plate Ⅱ6 can be moved up and down on both sides of the machine tool guide rail slider body 2, and can protect the machine tool guide rail slider body 2 together with the U-shaped cover 4 in the protective state. Move until the upper end surface is lower than the upper end surface of the guide rail 201, without causing interference when the machine tool is working normally (such as figure 2 As shown); the U-shaped cover 4 opening faces downward, and the two sides of the U-shaped cover 4 are symmetrically provided with limit protrusions 401, and the corresponding positions on the side plate I3 and side plate II6 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com