Machining equipment for intelligent edging and trimming after mold pressing of shoe soles

A processing equipment and edge grinding technology, applied in metal processing equipment, machine tools suitable for grinding workpiece edges, grinding/polishing equipment, etc. The effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

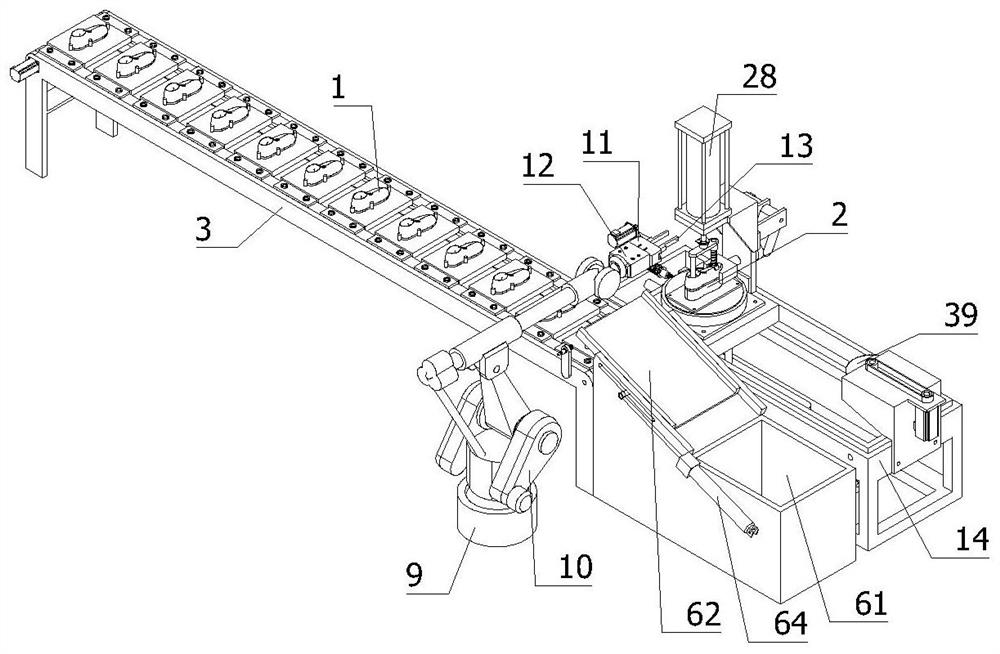

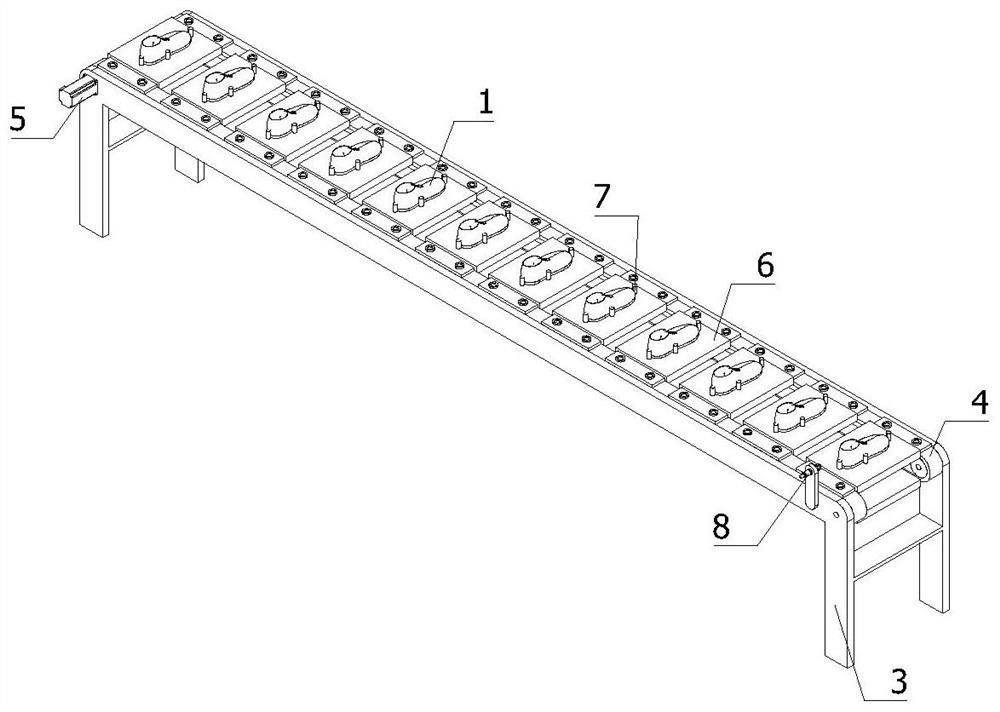

[0083] refer to Figure 1 to Figure 10 As shown, a kind of intelligent edging and trimming processing equipment for shoe sole after molding, including:

[0084] Feeding component for conveying batches of unfinished shoes 1;

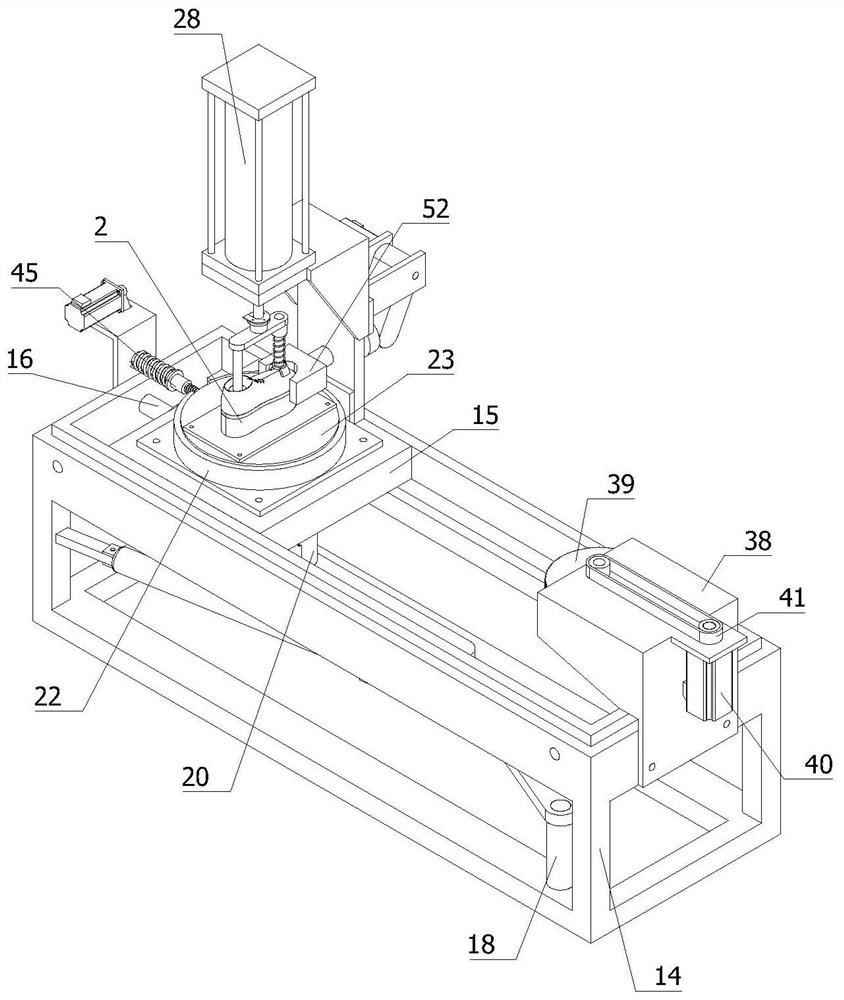

[0085] The material-moving component is used to move the shoe 1, the material-moving component is arranged at the end of the feeding component, and the moving direction of the material-moving component is parallel to the feeding direction of the feeding component;

[0086] The rotating component is used to drive the shoe 1 to rotate, and the rotating component is arranged on the material moving component;

[0087] The shoe holder 2 is used to support the shoe 1, the shoe holder 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap