Gypsum board stack crossing table conveying automatic control method and conveying device

A conveying device and gypsum board technology, which is applied in the directions of automatic packaging control, transportation and packaging, packaging, etc., can solve the problems of waste eyes and low packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

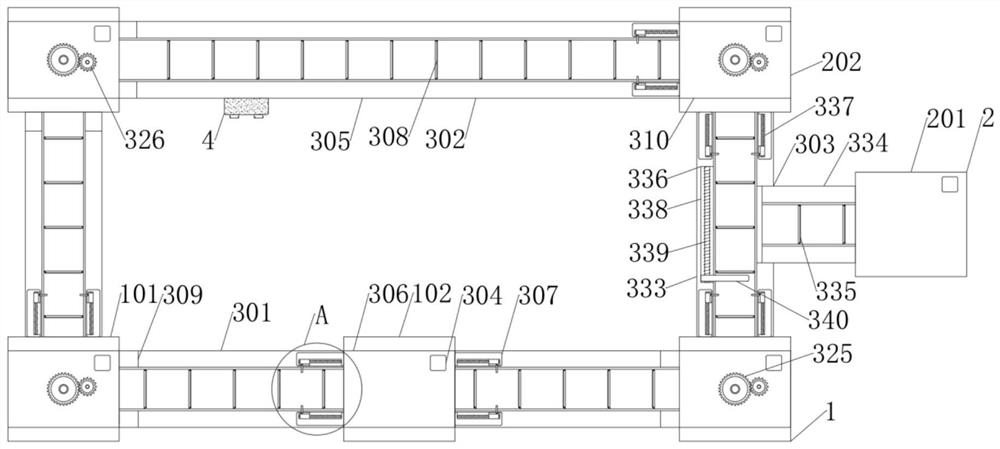

[0042] like Figure 1 to Figure 3 As shown, the present invention provides a gypsum board cross-stack conveying device, including a first storage area 1 and a second storage area 2 for storing gypsum boards, and the first storage area 1 and the second storage area 2 are jointly arranged There is a transfer transport device 3, and the transfer transport device 3 is connected with a control unit 4, and the gypsum board is transferred from the second storage area 2 to the first storage area 1 through the transfer transport device 3 for automatic packaging;

[0043] The first storage area 1 includes a first stacking platform 101 and two first finished product areas 102;

[0044] The second storage area 2 includes a second stacking platform 201 and two second finished product areas 202;

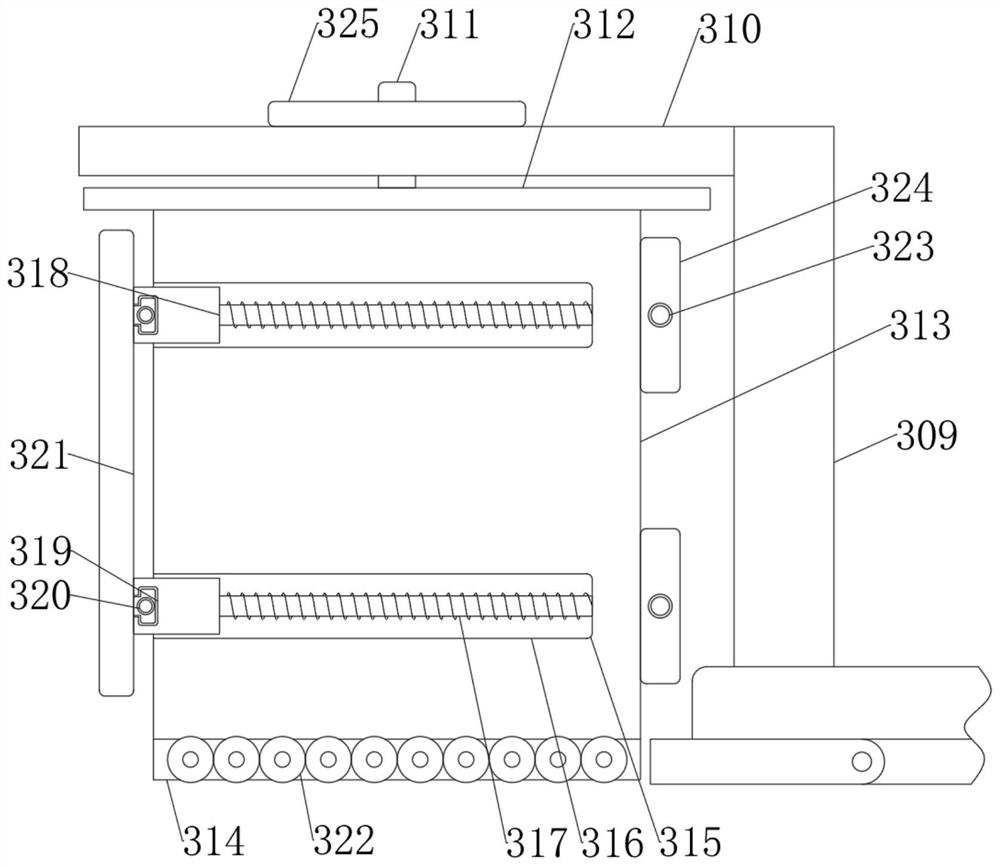

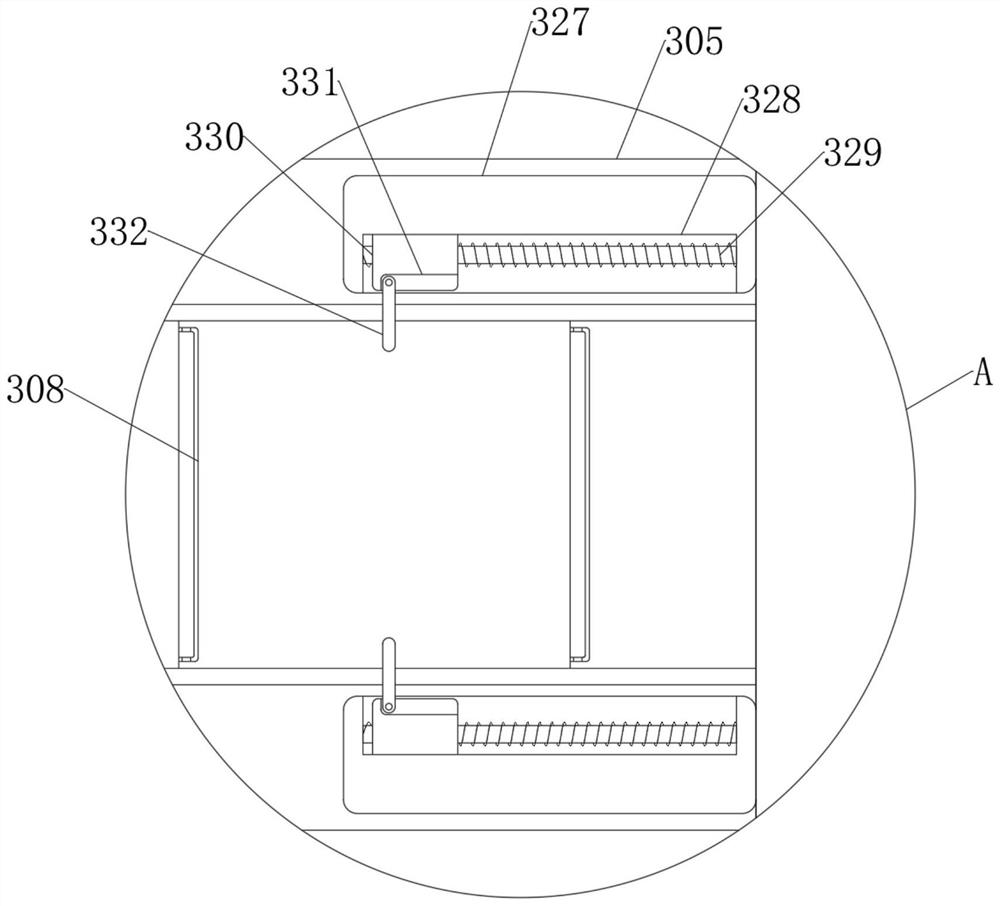

[0045] The transfer transport device 3 includes a plurality of first single-region conveying devices 301 and a plurality of second single-region conveying devices 302 with the same structure as t...

Embodiment 2

[0097] The present invention also provides an automatic control method for conveying a cross-stack conveying device, comprising steps;

[0098] S100, the gypsum boards are stacked on the first stacking platform and the second stacking platform, and the storage status of the gypsum boards in each area in the first storage area and the second storage area is monitored through the sensing element;

[0099] S200, when the transfer-out areas of the gypsum boards in the first stacking platform, the first finished product area, the second stacking platform, and the second finished product area meet the full stack, and when the gypsum board receiving area meets the condition of empty boards, pass The control unit activates the corresponding first single-zone conveying device and the second single-zone conveying device or partition conveying device to transport the gypsum board to the corresponding zone along the transport direction;

[0100] S300, the gypsum board is transported to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com