Building construction feeding machine based on positioning transmission

A technology for building construction and transmission mechanism, applied in the field of feeding machines, can solve the problems of inability to discharge, waste of materials, spilling, etc., and achieve the effects of improving utilization, improving convenience, and improving functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

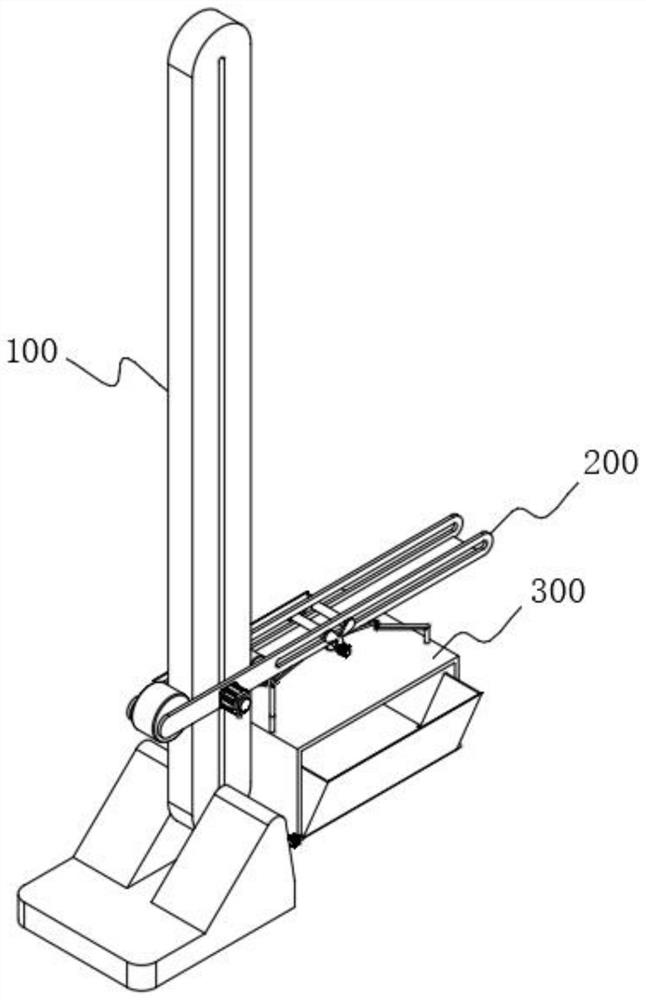

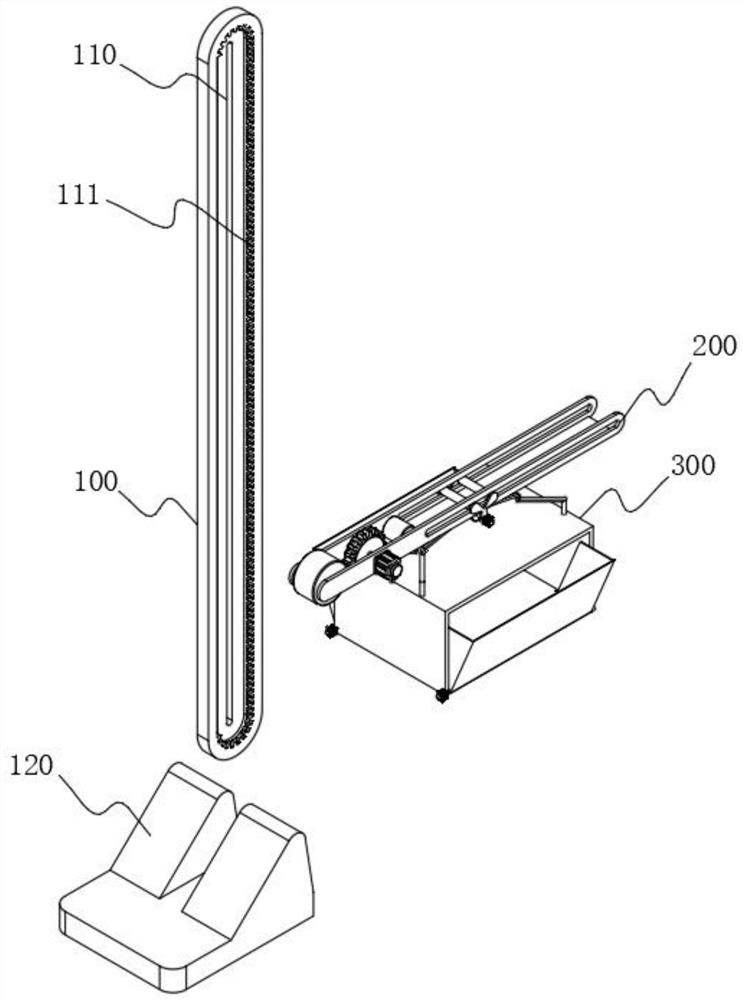

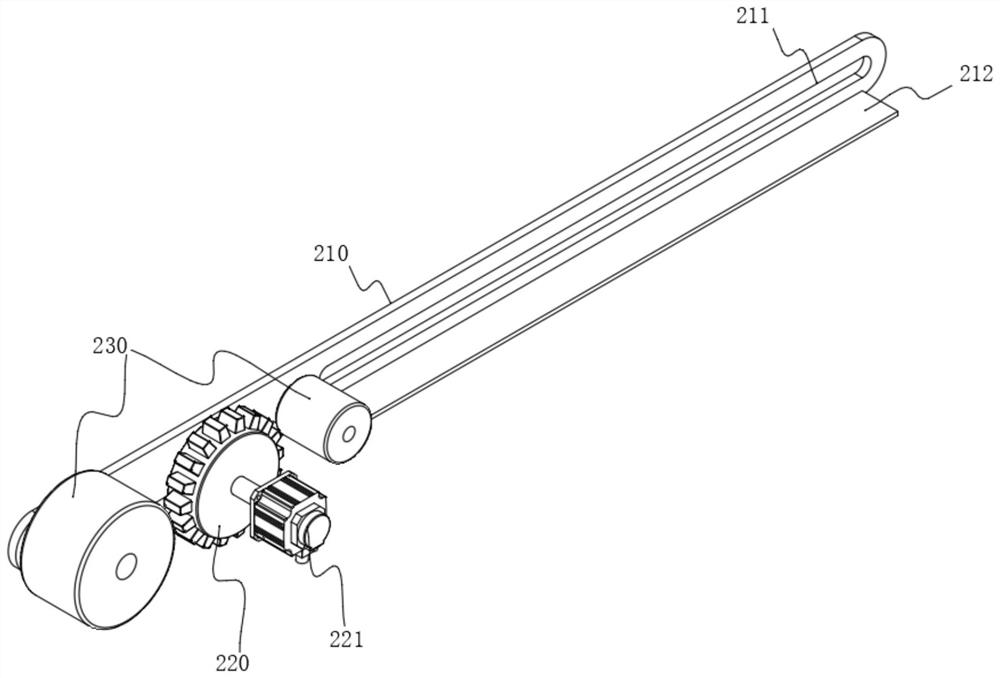

[0041] see figure 1 and figure 2 As shown, the purpose of this embodiment is to provide a construction loading machine based on positioning transmission, including a transmission mechanism 200 and a carrying mechanism 300 arranged at the bottom of the transmission mechanism 200. The carrying mechanism 300 includes a feeding box 330, and the transmission mechanism 200 Comprising two transmission racks 210, the transmission rack 210 is symmetrically arranged, and one side between the two transmission racks 210 is rotatably connected with a drive gear 220, and one end of the drive gear 220 is equipped with a drive motor 221, and the external device of the drive gear 220 There is a positioning frame 100, and the positioning frame 100 is provided with a positioning track 110 corresponding to the moving direction of the driving gear 220. The driving gear 220 is meshed with the positioning tooth groove 111 provided on the inner wall of the positioning track 110, and the two transmis...

Embodiment 2

[0047] In order to adapt to the installation of the construction site, this embodiment improves the embodiment, see for details figure 2 As shown, wherein: the bottom of the positioning frame 100 is provided with a support base 120, and the support base 120 is pre-buried in the ground for fixing the positioning frame 100. After use, the support base 120 pre-buried in the ground can be dug out, and It can also solve the problem that the ground cannot stably support the positioning frame 100 due to the soft soil on the bottom surface of the construction site.

Embodiment 3

[0049] In order to reduce the vibration amplitude during the movement of the transport frame 210, the difference between this embodiment and Embodiment 1 is that, please refer to image 3 As shown, wherein: the outer walls of the two auxiliary gears 230 are attached to the outer walls of the positioning frame 100, so that the outer walls of the positioning frame 100 are clamped by the cooperation of the two auxiliary gears 230 and the driving gear 220, so as to reduce the movable position of the transmission frame 210. range, thereby reducing the vibration amplitude during the moving process of the transmission frame 210, and at the same time, the rotation of the auxiliary gear 230 can also reduce the wear on the outer wall of the positioning frame 100 and prolong its service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com