Assembly type building cold bending profile

A prefabricated and architectural technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of operator inconvenience, inconvenient movement, etc., and achieve the effect of simple assembly and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

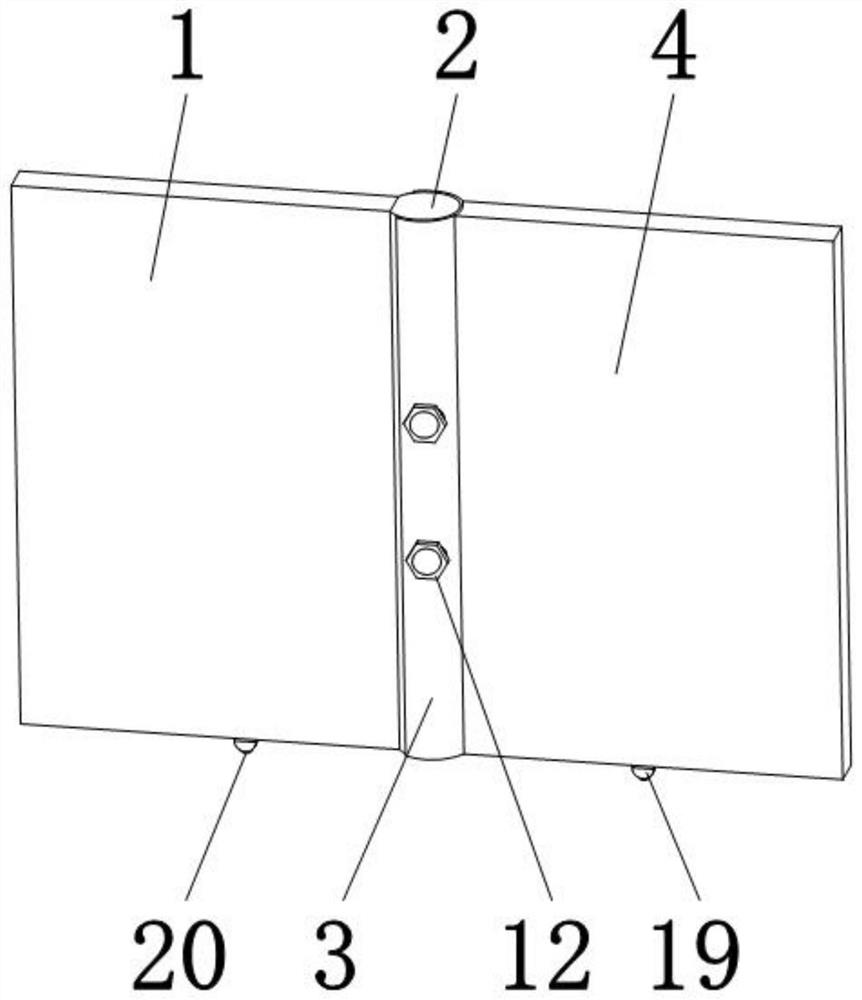

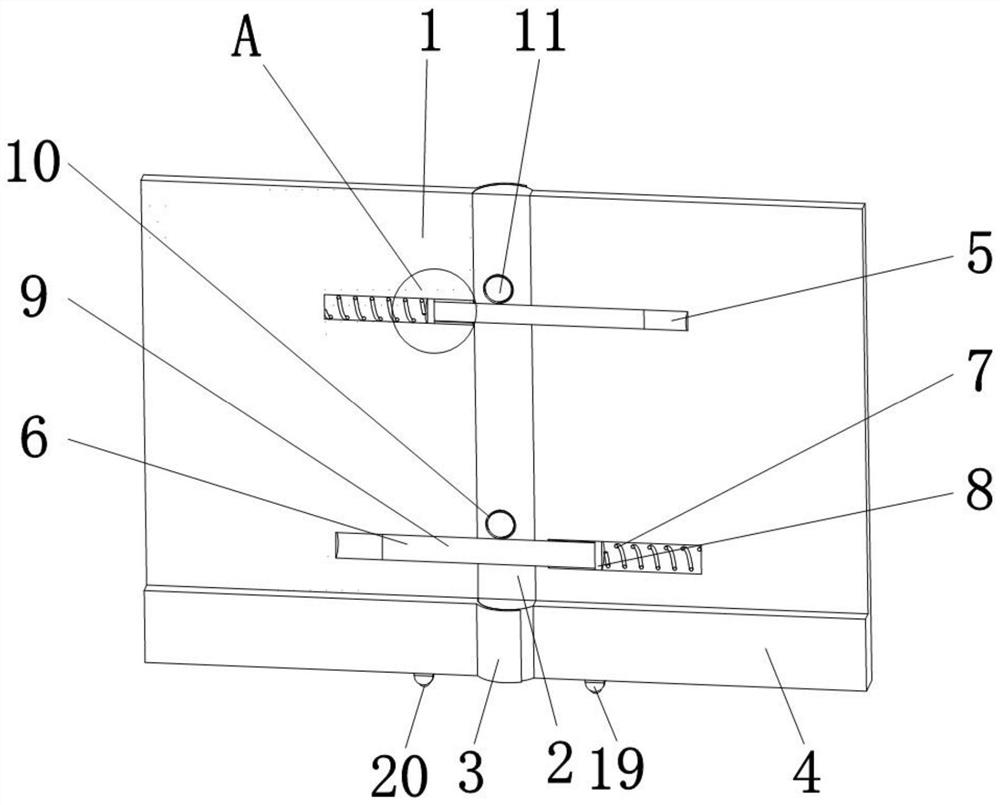

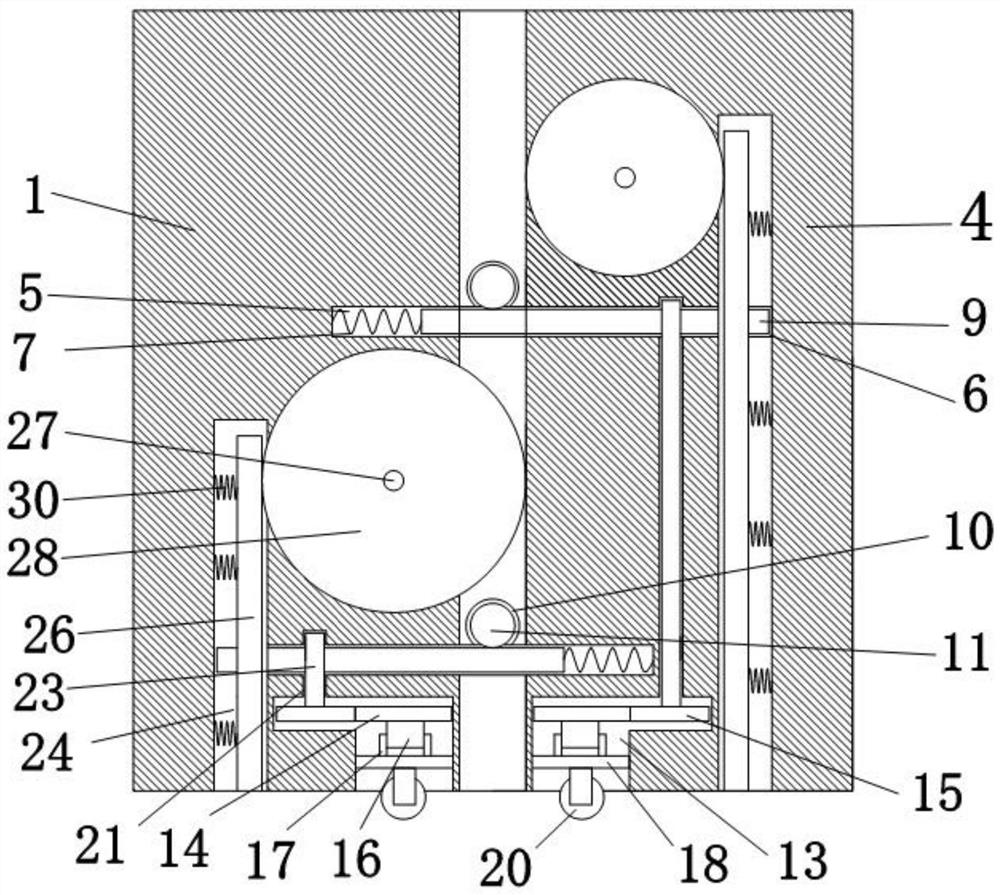

[0035] Such as Figure 1 to Figure 5 As shown, the present invention provides a prefabricated building cold-formed profile, including an assembly fixing plate 1, the right end of the assembly fixing plate 1 is provided with a fixed shaft 2, the outer surface of the fixed shaft 2 is movably socketed with a movable arc sleeve 3, and the movable arc The right end of the sleeve 3 is provided with an assembly movable plate 4, and one side of the assembly fixed plate 1 and the assembly movable plate 4 is provided with a mounting groove 5 and a fixing groove 6, the mounting groove 5 is opposite to the fixing groove 6, and the inner cavity of the mounting groove 5 The right side of the back spring 7 is provided with a return spring 7, the other end of the return spring 7 is provided with a connecting block 8, and the left side of the connecting block 8 is provided with a fixed rod 9, and the other end of the fixed rod 9 runs through the installation groove 5 and extends to the end of t...

no. 2 example

[0046] Based on a prefabricated building cold-formed profile provided in the first embodiment, the device uses rollers 20 to realize the movement and support of the device, but the rollers 20 alone are not enough to achieve stable support for the entire device, especially for disassembly. During installation, it is necessary to lift the assembly fixed plate 1 and the assembly movable plate 4. At this time, because the rotating gear rod 23 is located inside the notch 13, it is inconvenient to manually operate. After determining the appropriate assembly position, assemble the fixed plate 1 and The lowering height of the assembly movable plate 4 cannot be precisely and smoothly controlled, and when the assembly fixed plate 1 and the assembly movable plate 4 are assembled on uneven ground, the device can only provide temporary support through the rollers 20, and cannot guarantee the stability of the support sex. In order to solve this problem and ensure the stability, accuracy and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com