Concave wheel rotor-type valve mechanism

A gas distribution mechanism and rotor type technology, which is applied in the field of concave wheel rotor type gas distribution mechanism, can solve the problems of inconspicuous energy-saving measures, short life span, large energy consumption of the gas distribution mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

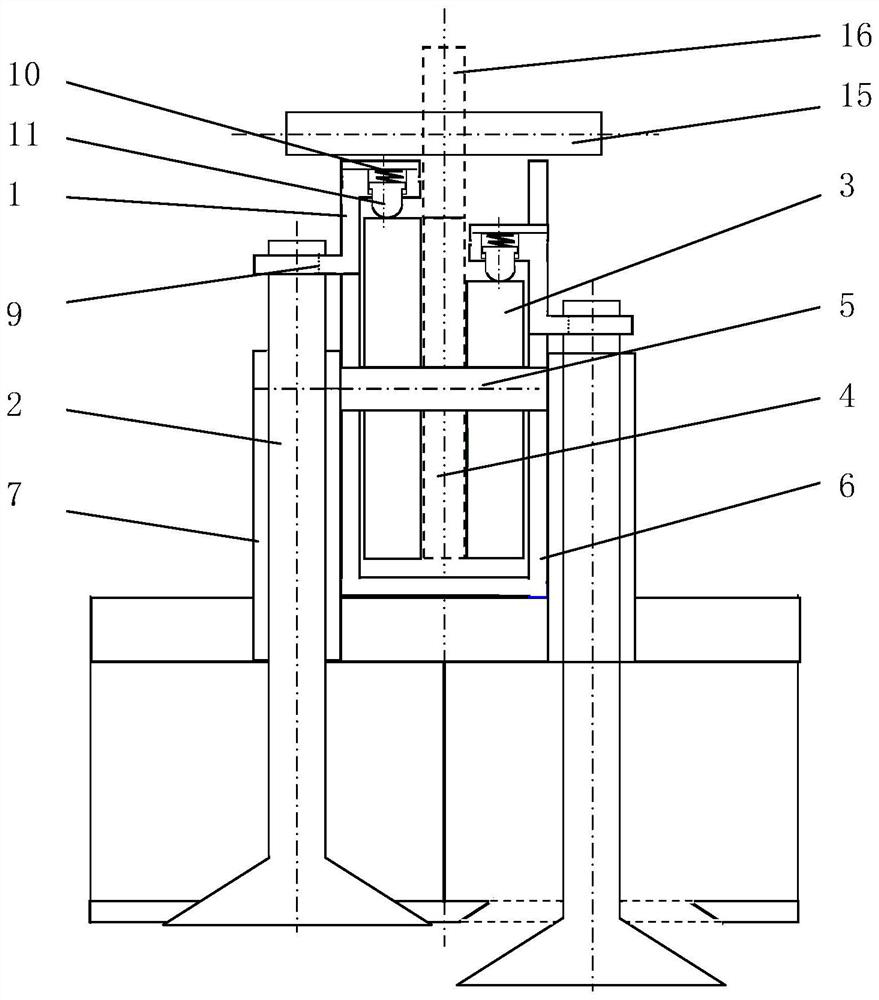

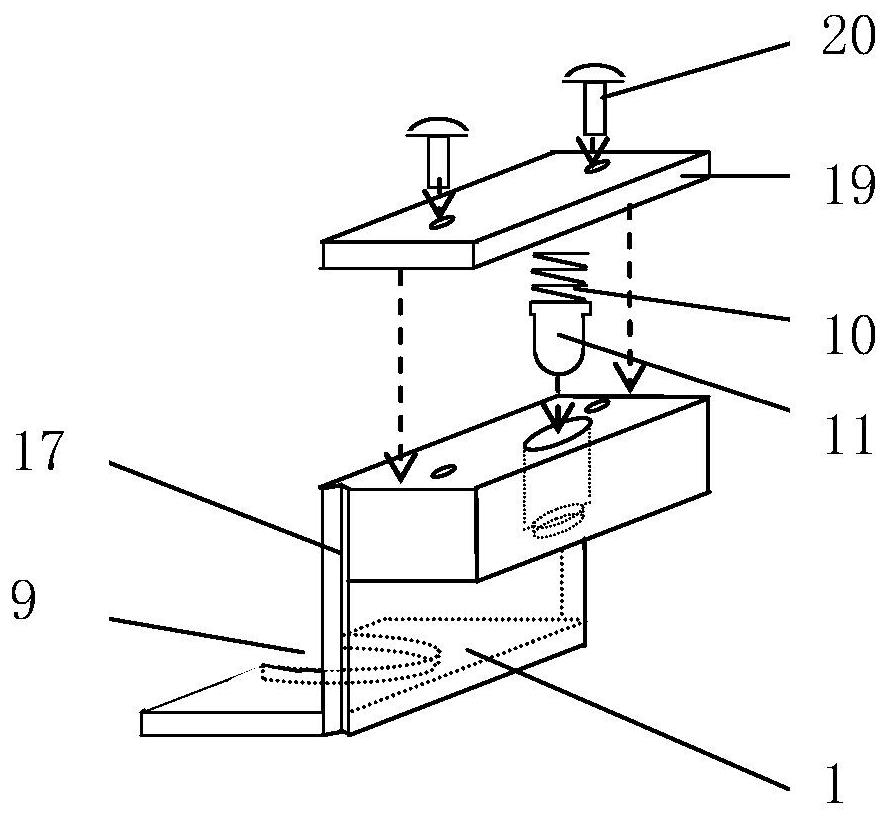

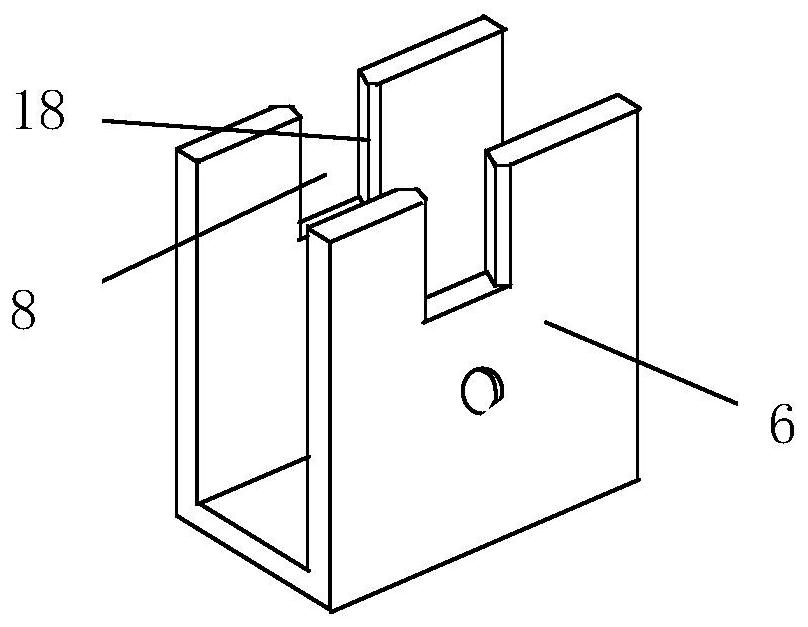

[0022] like figure 1 As shown, the concave wheel rotor type gas mechanism is mainly composed of a concave wheel rotor and a linkage body 1, and the concave wheel rotor passes the valve 2 by the linkage 1; the concave wheel rotor includes two revertork 3, one is intake concave The wheel, one is an exhaust valve, and there is a driven gear 4 between the two dorsaties, and the three are fixed to the rotating shaft 5 through the bearing, which is the conspending wheel rotor; the concave wheel rotor passes through the rotor bracket 6 is set between the two valve catheters 7; the linkage 1 is a stepped shape (see figure 2 ), The vertical side of the step is inserted into the limit frame 8 on the side of the rotor bracket 6, which limits it to move up and down in the frame (see image 3 The bottom layer of the step is provided with a U-port 9. The tip end of the valve 2 is provided with a tap rod ring slot, and the valve 2 is provided on the U-port 9 of the linkage 9, which is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com