A one-sided synchronizer

A synchronizer and unilateral technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of high processing cost, complex shape of the slider groove, complex processing technology of the slider limit structure, etc., to achieve low cost, Snap-in installation is convenient and fast, and the shape is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

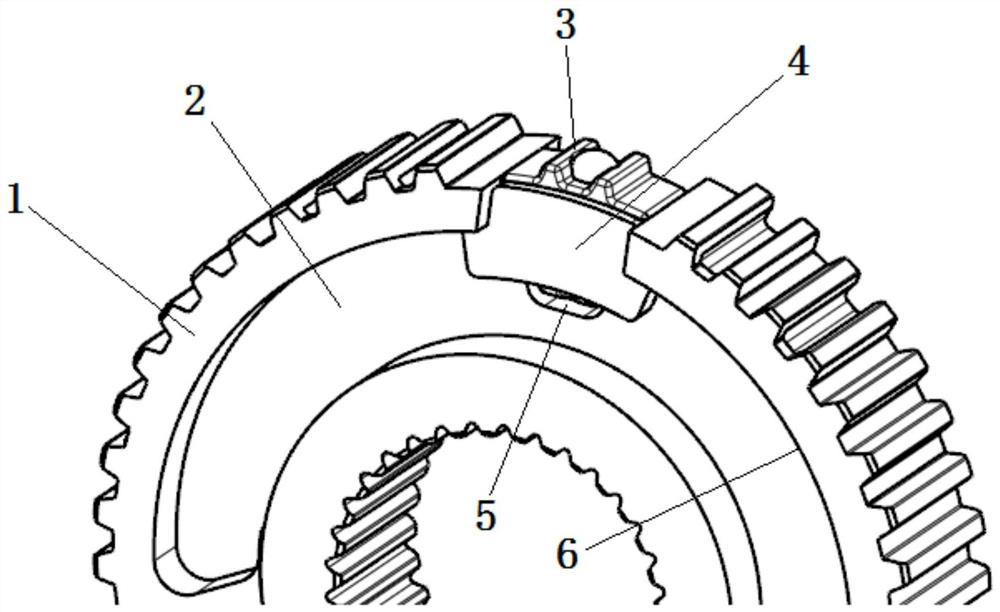

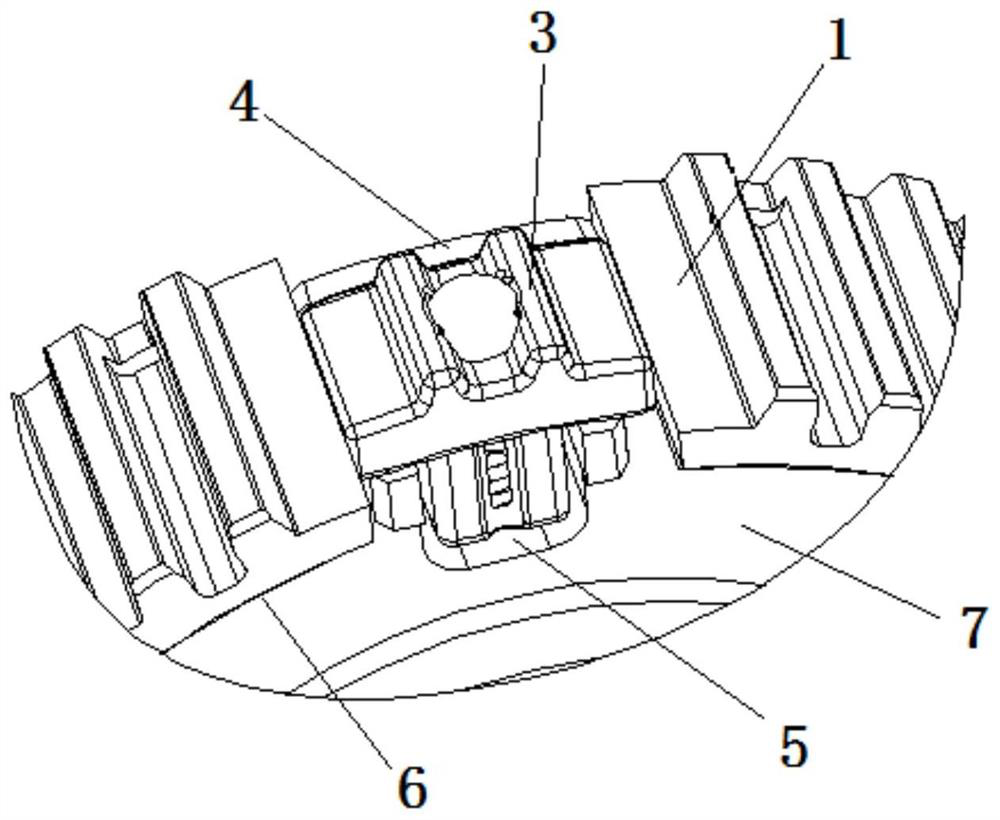

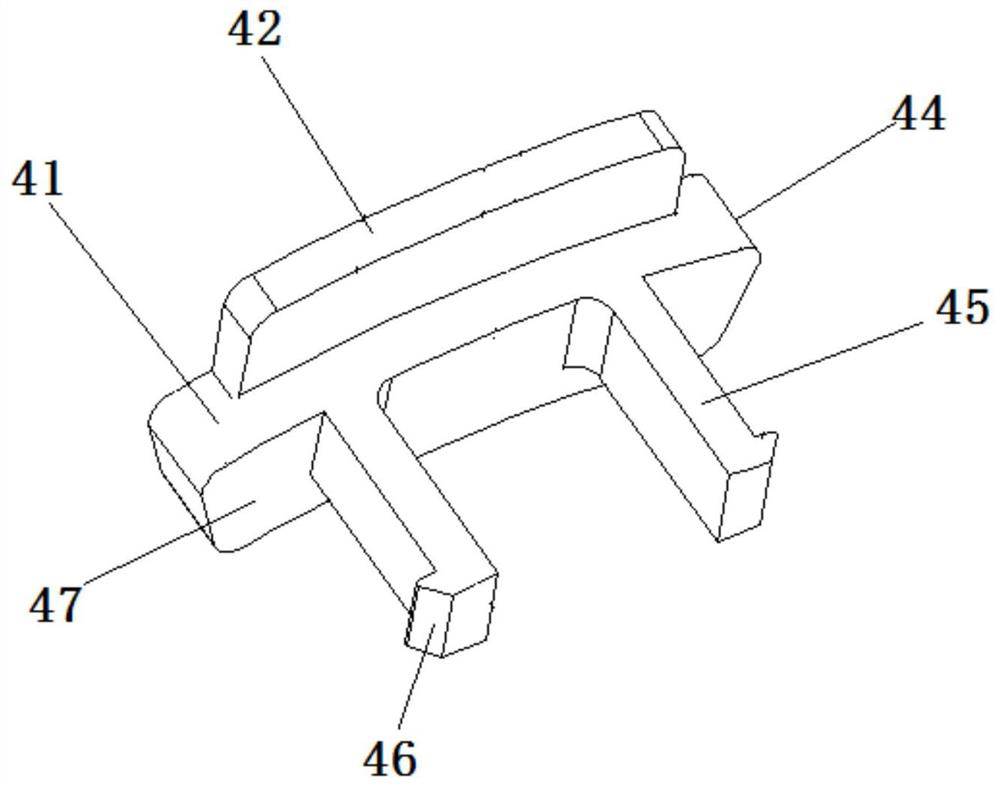

[0015] like figure 1 , figure 2 As shown, the unilateral synchronizer includes a gear hub 1 and a slider 3 installed in the slider slot 5 of the gear hub 1. The gear hub 1 has a left end face 7, a right end face 2 and an inner arc surface 6. The slider A limit block 4 is clamped in the slot 5 to close one end of the slider slot 5, such as image 3 As shown, the limit block 4 is integrally formed of plastic, and is composed of a limit block 44 and two clamping feet 45 perpendicular to the limit block 44. The upper side 41 of the limit block 44 is an arc that matches the inner arc of the gear hub 1. The surface 6 is an arc surface with the same radian. The limit block 44 extends upward from the middle of the upper side surface 41 to form a stop block 42 . like Figure 4 , Figure 5 As shown, the two sides of the slider slot 5 are symmetrical two-stage ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com