Multi-stage sliding telescopic arm

A technology of telescopic arm and sliding seat, which is applied in the field of telescopic arm, can solve problems such as difficulty in meeting actual requirements, insufficient length of three-stage telescopic arm, etc., and achieve the effects of precise positioning, dust prevention, and long telescopic distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

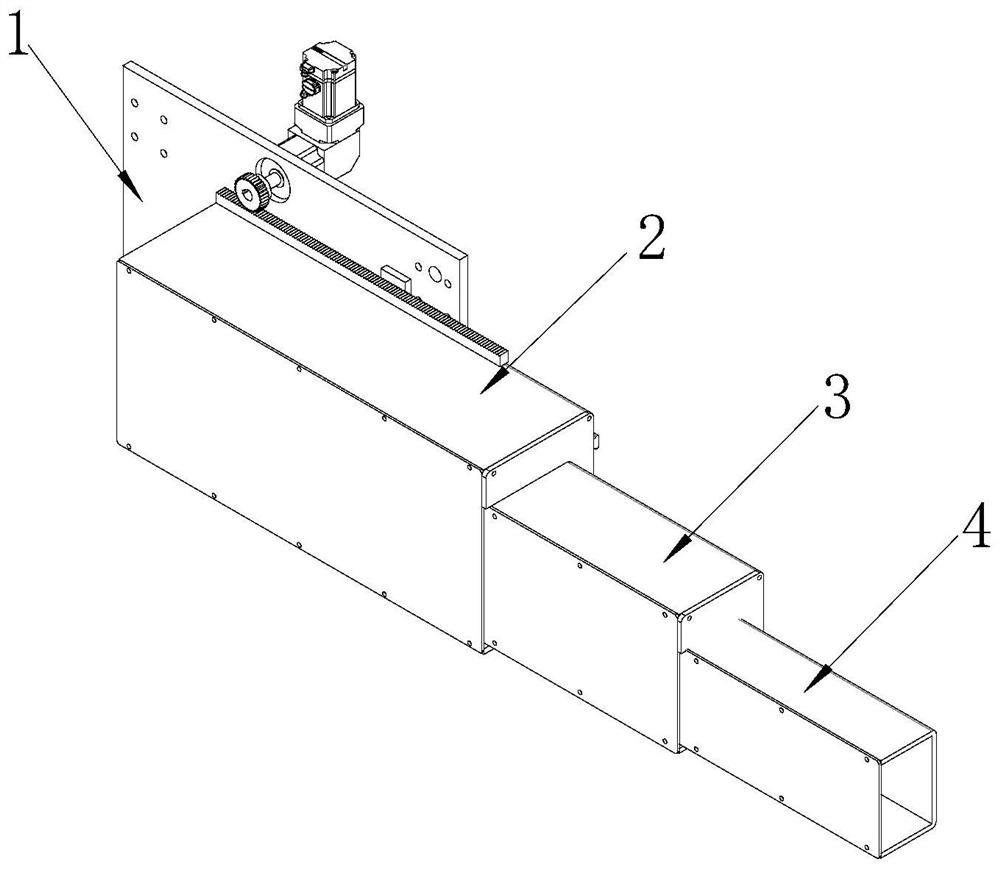

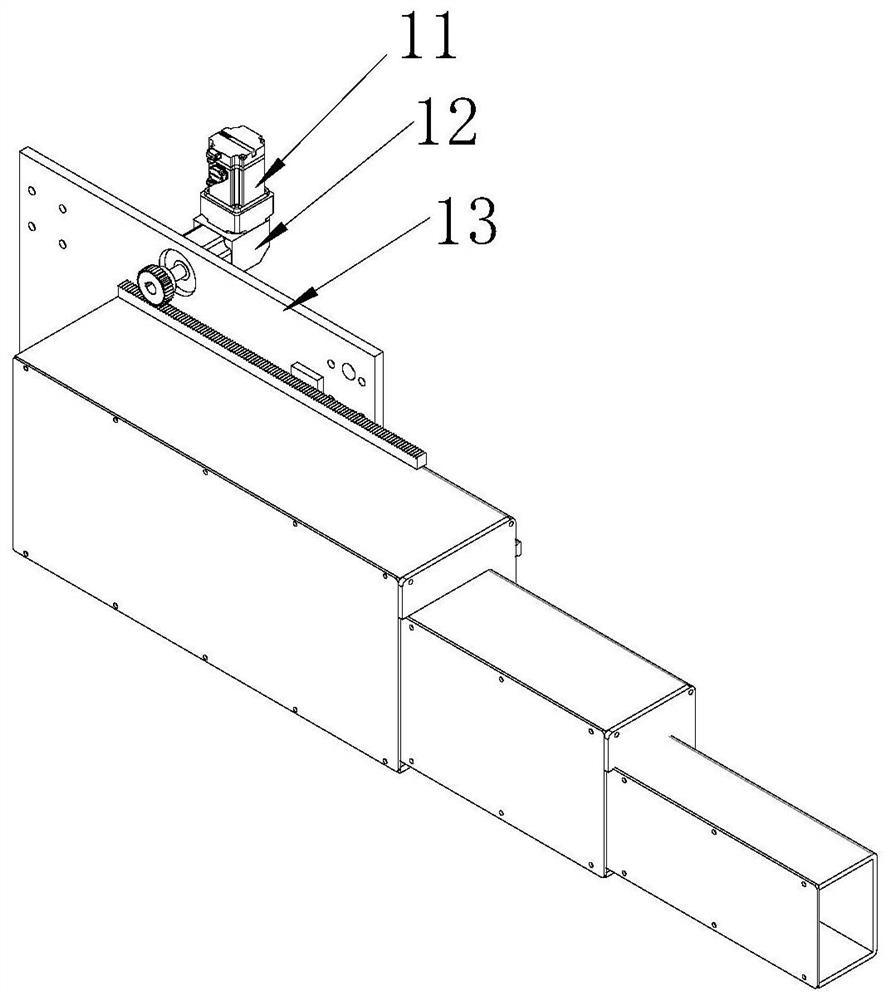

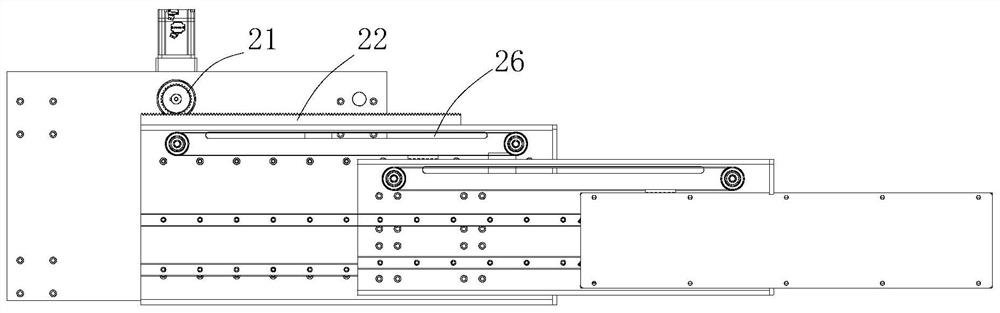

[0059] In order to set forth the present invention better, below with reference to appended Figure 1-9 The present invention is further described in detail.

[0060] An embodiment of the present invention provides a multi-stage sliding telescopic arm, which includes:

[0061] Basic arm, N telescopic arms;

[0062] The N telescopic arms include: a first stage telescopic arm, a second stage telescopic arm...the Nth stage telescopic arm;

[0063] The first-stage telescopic arm is installed on the basic arm; the second-stage telescopic arm is nested and slid in the first-stage telescopic arm; the N-stage telescopic arm is nested and slid in the N-1-stage telescopic arm ; Wherein, N is a positive integer greater than or equal to 2;

[0064] A sliding assembly is arranged between the basic arm and the first-stage telescopic arm, between the first-stage telescopic arm and the second-stage telescopic arm, and between the N-1-th stage telescopic arm and the N-stage telescopic arm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com