PCB detection system and method

A detection system and detection method technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as automation constraints, lack of height information, etc., to achieve accurate and efficient acquisition, efficient access integration, accurate and stable detection. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

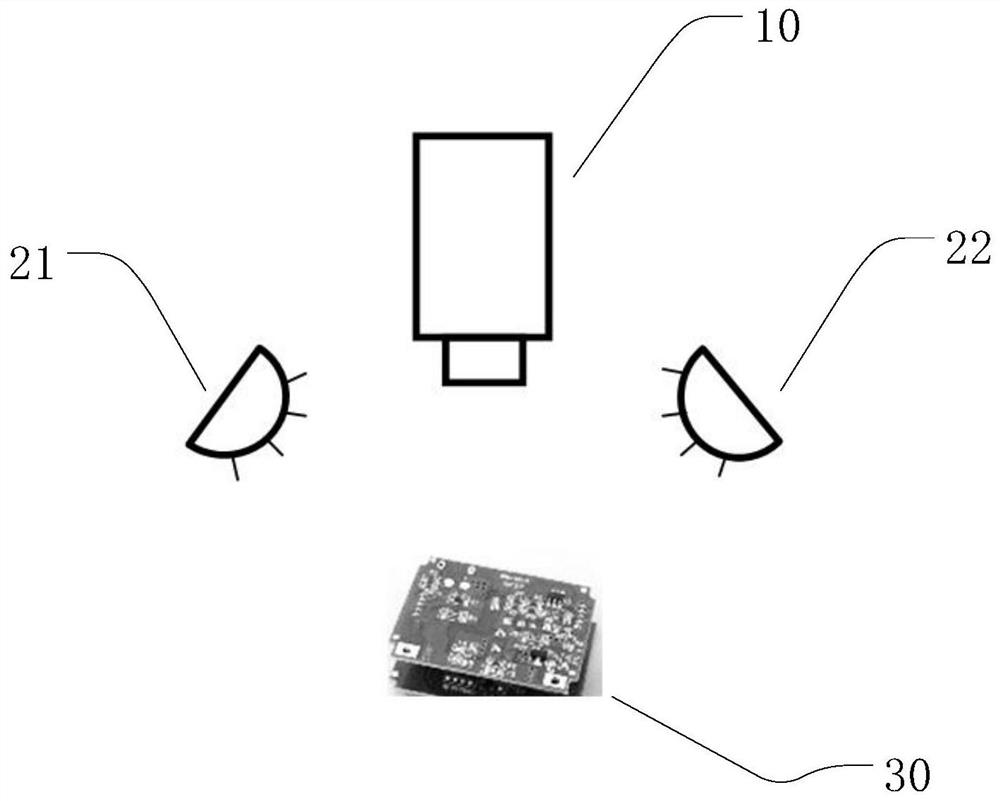

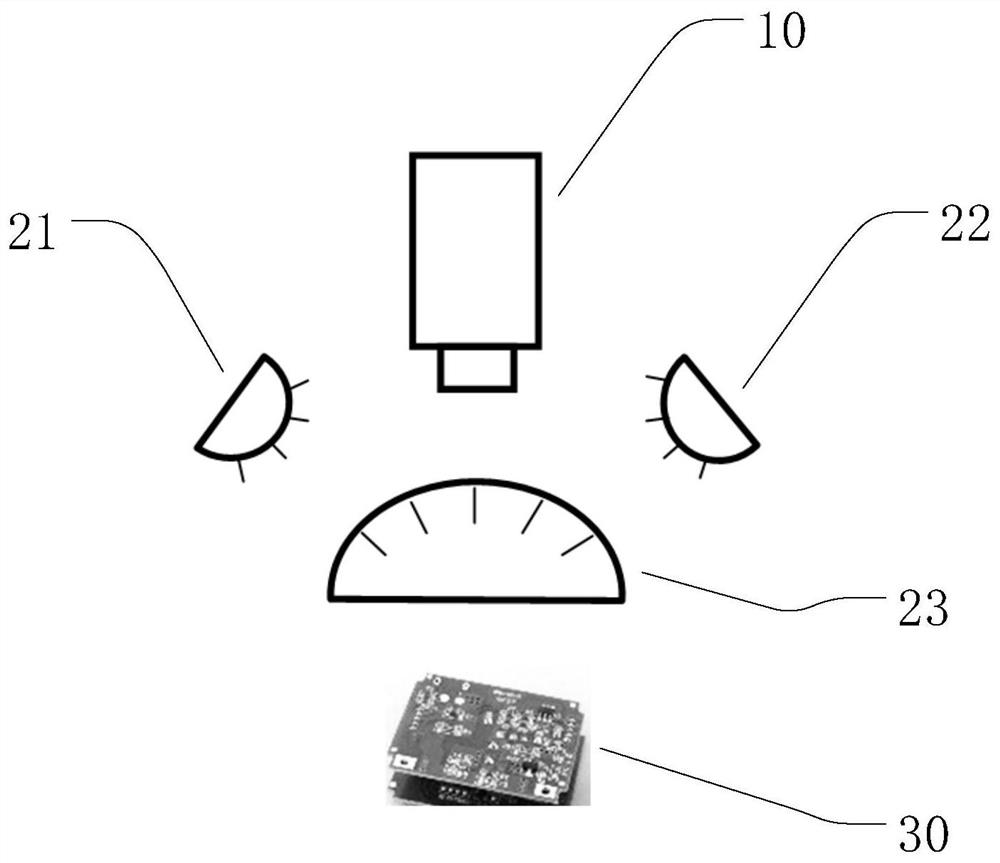

[0027] According to one or more embodiments, such as figure 2 As shown, a PCB inspection system includes a light field camera, the lens of the light field camera is facing the PCB to be inspected, and is used to obtain images including the soldering status of components on the PCB; two light sources, the light rays of these two light sources emit To the PCB to be tested, it is used to help the light field camera obtain an image of the soldering state of the PCB components.

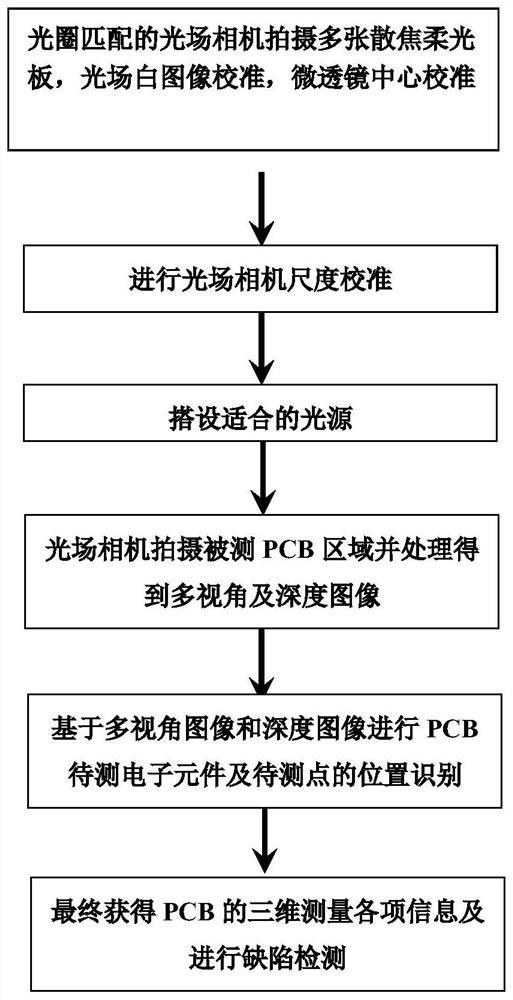

[0028] According to one or more embodiments, such as figure 1 As shown, for the PCB inspection system, the inspection process for PCB includes,

[0029] Adjust the focal length and / or aperture of the light field camera to obtain a plurality of defocused soft light pure color calibration plates of the PCB components, and obtain a light field white image of the PCB components;

[0030] Calibrate the white image of the light field, and calibrate the center of the microlens of the light field camera;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com