Draw texturing machine

A processing machine and false twisting technology, applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problem of yarn winding on rotating parts, failure of yarn hanging operation, difficulty of yarn hanging operation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described below with reference to the drawings.

[0044] (Overall structure of false twist processing machine)

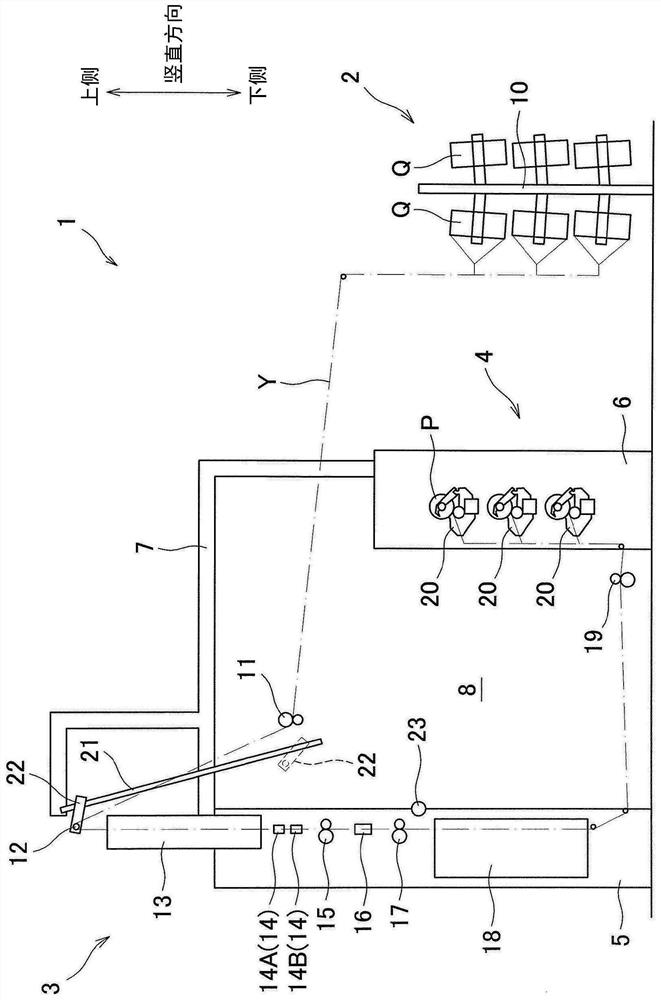

[0045] figure 1 It is an overall configuration diagram of the false twist processing machine 1 according to this embodiment. Such as figure 1 As shown, a false twist processing machine 1 has a yarn supply section 2 that supplies a plurality of yarns Y, a processing section 3 that performs false twist processing on a plurality of yarns Y supplied from the yarn supply section 2, and a false twist processing section 3 that is processed. A plurality of twisted yarns Y are wound to form a winding section 4 of a plurality of packages P.

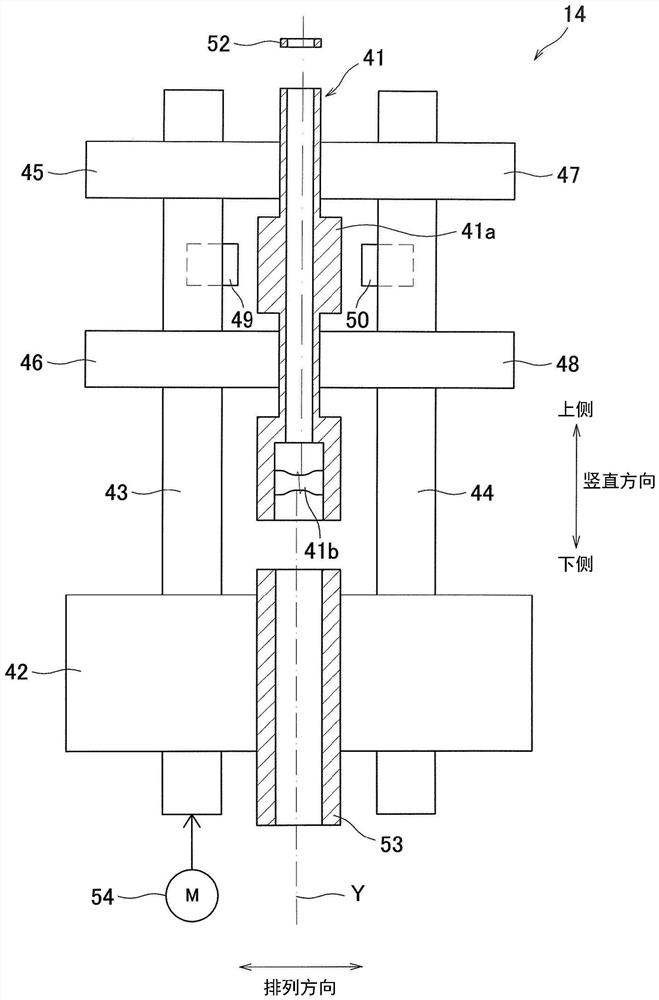

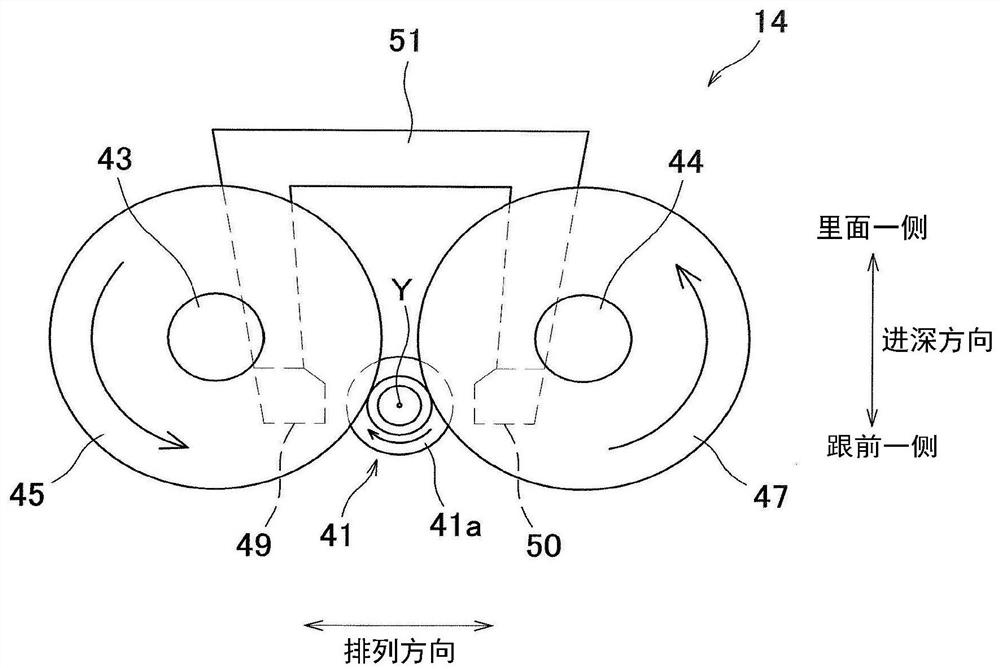

[0046] The yarn supply unit 2 has a creel 10 holding a plurality of yarn supply packages Q, and supplies a plurality of yarns Y to the processing unit 3 . In the processing section 3, the first yarn feeding roller 11, the anti-twist yarn guide 12, the first heating device 13, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com