Pivot bearing for steering system

A swing bearing and steering system technology, applied in the field of steering systems, can solve problems such as limited swing range and unpopularity, and achieve the effects of eliminating structural gaps, convenient swing, vibration and noise suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

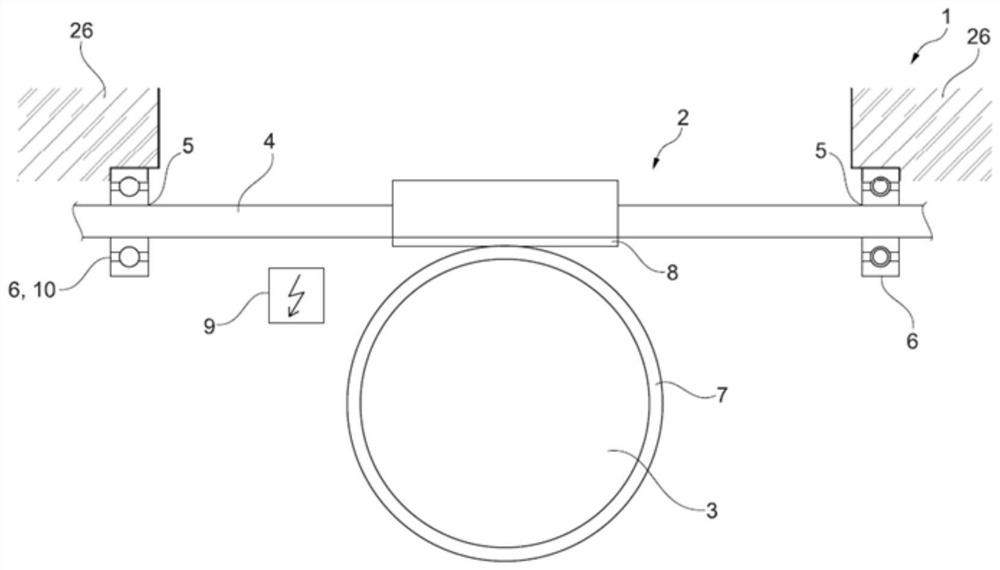

[0025] figure 1 An exemplary embodiment of a steering system 1 with pivot bearing 6 according to the invention is shown. The steering system has a worm gear 2 via which the steering torque is transmitted from a worm shaft 4 to a worm wheel 3 . For this purpose, a toothing 7 is formed on the worm wheel 3 , which meshes with the toothing section 8 of the worm shaft 4 . The worm shaft 4 is mounted in the housing 26 of the worm gear 2 on bearing points 5 , preferably on at least two bearing points 5 . The worm shaft 4 is supported by means of the swivel bearing 6 . The steering system 1 is preferably designed as an electric power steering system 1 . For this purpose, the steering system 1 includes an electric power steering 9 , by means of which the driver's steering force is assisted in order to change the steering angle.

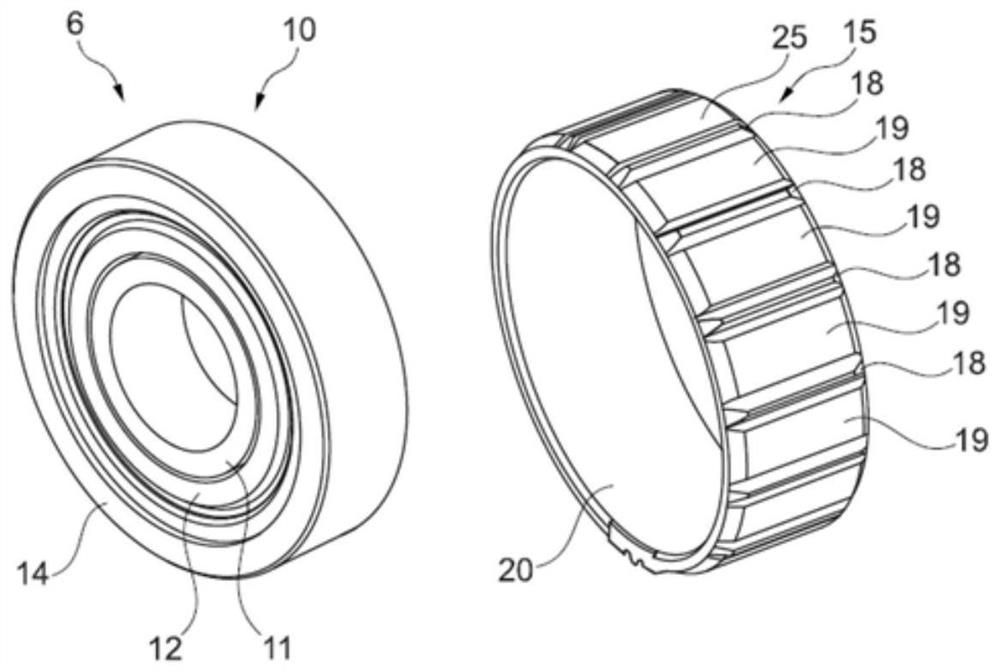

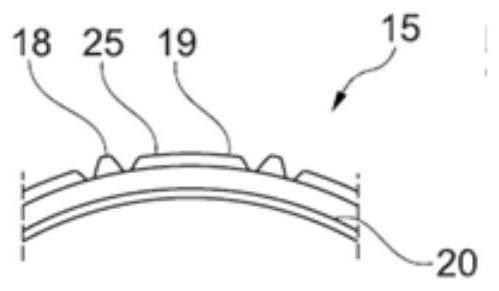

[0026] figure 2 An inventive swivel bearing 6 with a tolerance ring 15 is shown for the steering system 1 . The swivel bearing 6 is designed as a rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com