Belt Conveyor with Reversing Mechanism

A technology of belt conveyors and conveyors, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large investment in supporting equipment, complicated docking process, limited use area, etc., and achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

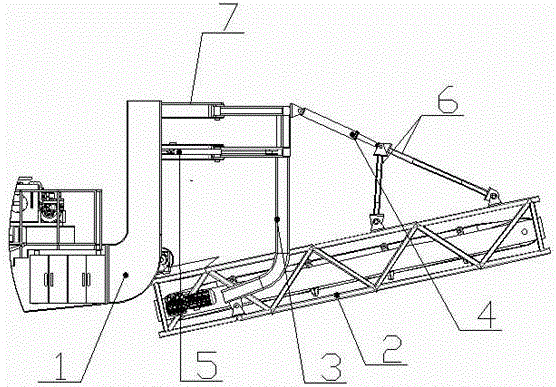

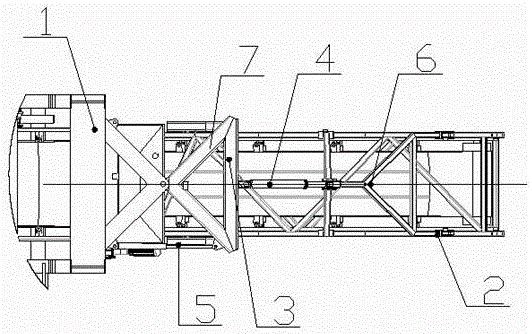

[0011] Example: such as figure 1 As shown, a cantilever 7 is connected to the upper end of the gantry 1, a cantilever 3 is connected to the cantilever 7, and a height adjustment cylinder 4 is hinged. The other end of the boom 3 is hinged with the tail section of the conveyor frame 2, the piston rod of the height adjustment cylinder 4 is connected with an extension connecting rod 6, and the extension connecting rod 6 is hinged with the front section of the conveyor frame 2, so that with the height By adjusting the expansion and contraction of the oil cylinder, the height adjustment of the conveyor outlet can be realized. The cantilever 7 adopts a two-section structure, and the two sections are connected with each other by a hinge. The number is two. The two cantilever 7 are arranged crosswise. Oil cylinder 5, just can take the lead dry boom 3 to rotate along with turning to the expansion and contraction of oil cylinder 5 like this, thereby realizes the turning to of conveyor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com