An automatic sealing device and method

A sealing device and sealing technology, which are applied to devices and coatings that apply liquid to the surface, can solve problems such as low efficiency, waste of glue consumption, unqualified products, etc., so as to improve the sealing effect and work. Efficiency, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

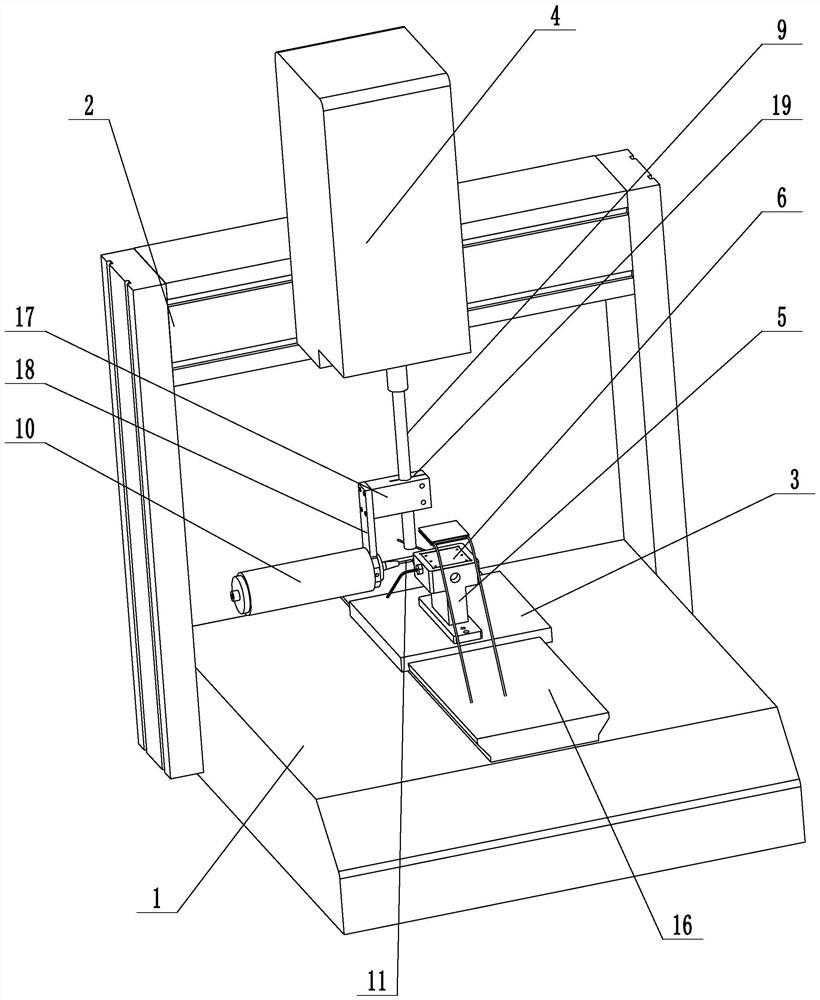

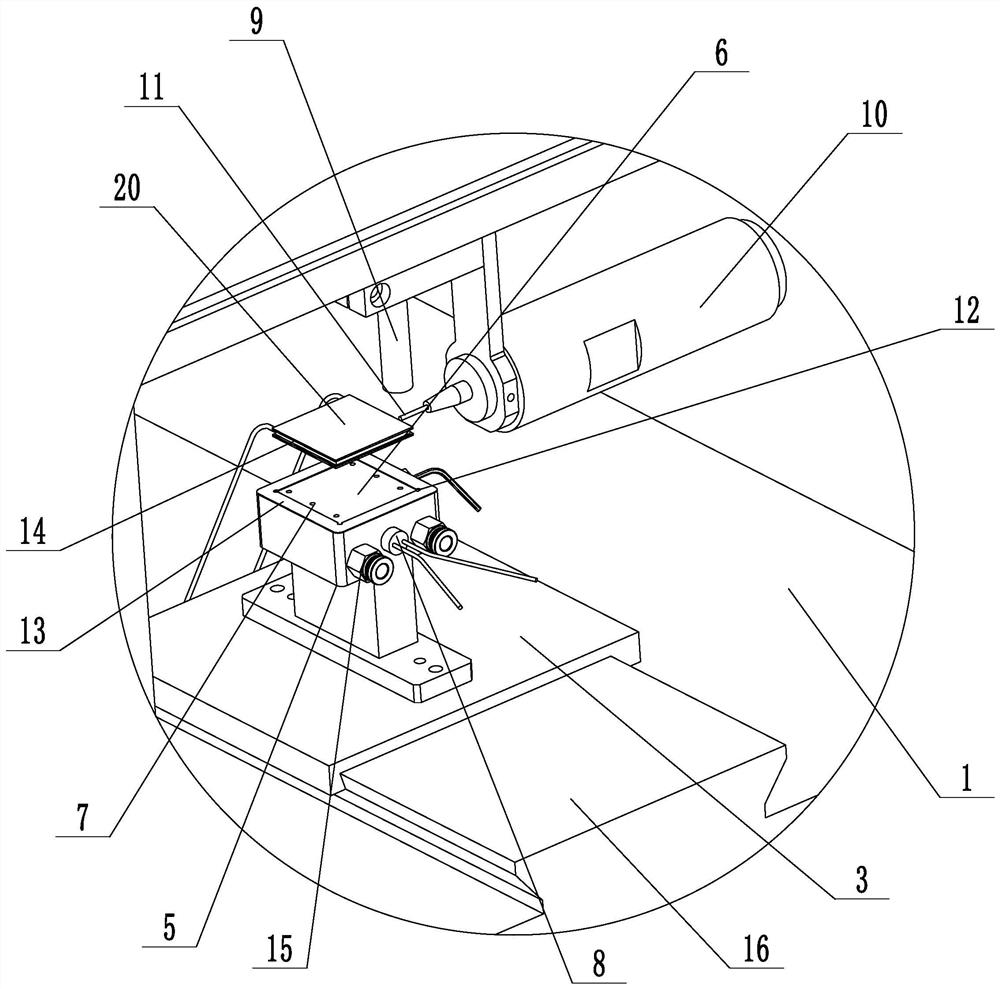

[0031] Example 1: An automatic sealing device (see attached figure 1 , attached figure 2 ), including the worktable 1, the frame 2, the base 3 that can move forward and backward is installed on the worktable, the sliding seat 4 that can move left and right is installed on the frame, and the limit seat 5 is installed on the base. The positioning groove 6 of the sealing product is provided with a number of negative pressure adsorption holes 7 on the bottom surface of the positioning groove, and an air suction cavity is arranged on the limit seat. A heater 8 is installed at the bottom of the positioning groove on the seat to make the temperature at the bottom of the positioning groove higher than the ambient temperature; a liftable rotating shaft 9 is installed on the sliding seat, and a glue gun 10 is installed on the rotating shaft. The end of the rubber head is placed on the axis of rotation of the shaft.

[0032] The positioning groove has a rectangular structure, and the ...

Embodiment 2

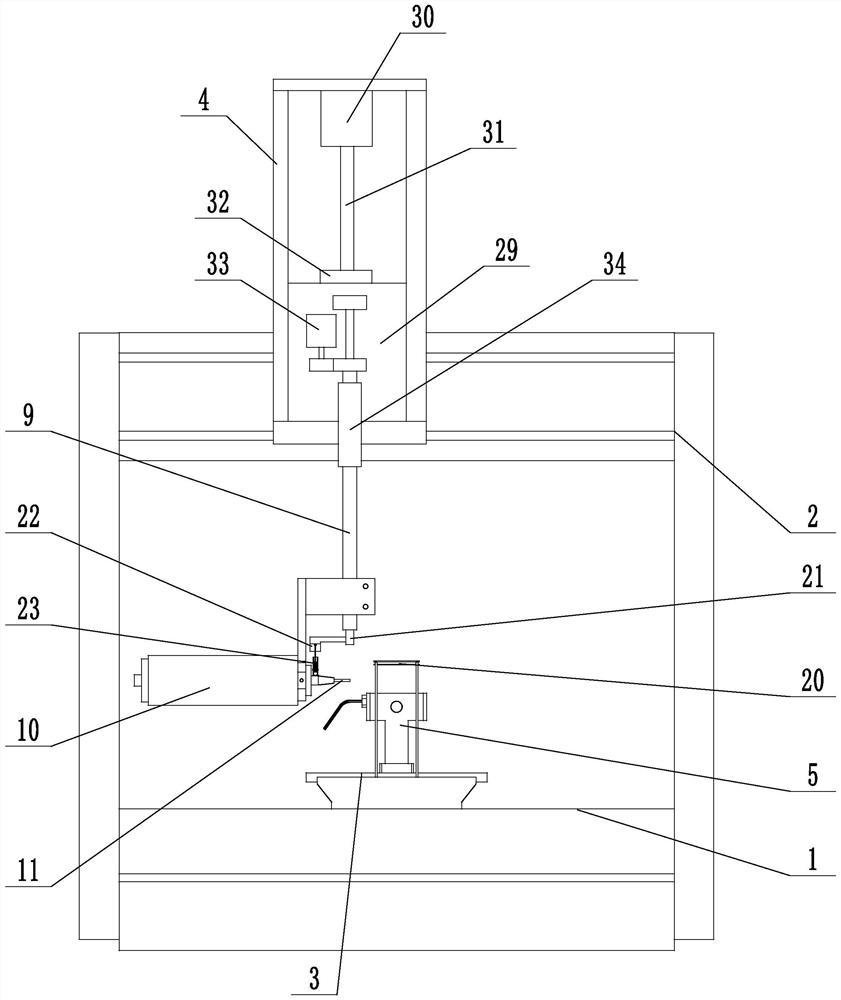

[0043] Example 2: An automatic sealing device (see attached image 3 , attached Figure 4 ), its features are similar to those in Embodiment 1, the main difference is that in this implementation, the sliding seat is connected with a vertical rod 21, the rotating shaft is in a hollow tubular structure, the vertical rod and the rotating shaft are movably sleeved together, and the lower end of the vertical rod extends out of the rotating shaft, and the vertical rod The lower end is connected with a push guide bar 22; the glue gun is connected to an impact cylinder 23 near the glue discharge head, and the lower end of the impact cylinder is communicated with the glue gun. Tightly connect the positioning pin 27, the upper end of the top rubber piston abuts on the positioning pin, the return spring abuts between the positioning pin and the pressurizing piston, the pressurizing piston is connected to the top rod 28, and pushes the lower surface of the guide bar from the middle to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com