A kind of concrete aggregate separation device and separation method thereof

A concrete aggregate and separation device technology, applied in the direction of solid separation, chemical instruments and methods, grids, etc., can solve problems affecting the work process, aggregate surface damage, aggregate stacking, etc., to improve the use effect and prevent violent The effect of collision and slowing down speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

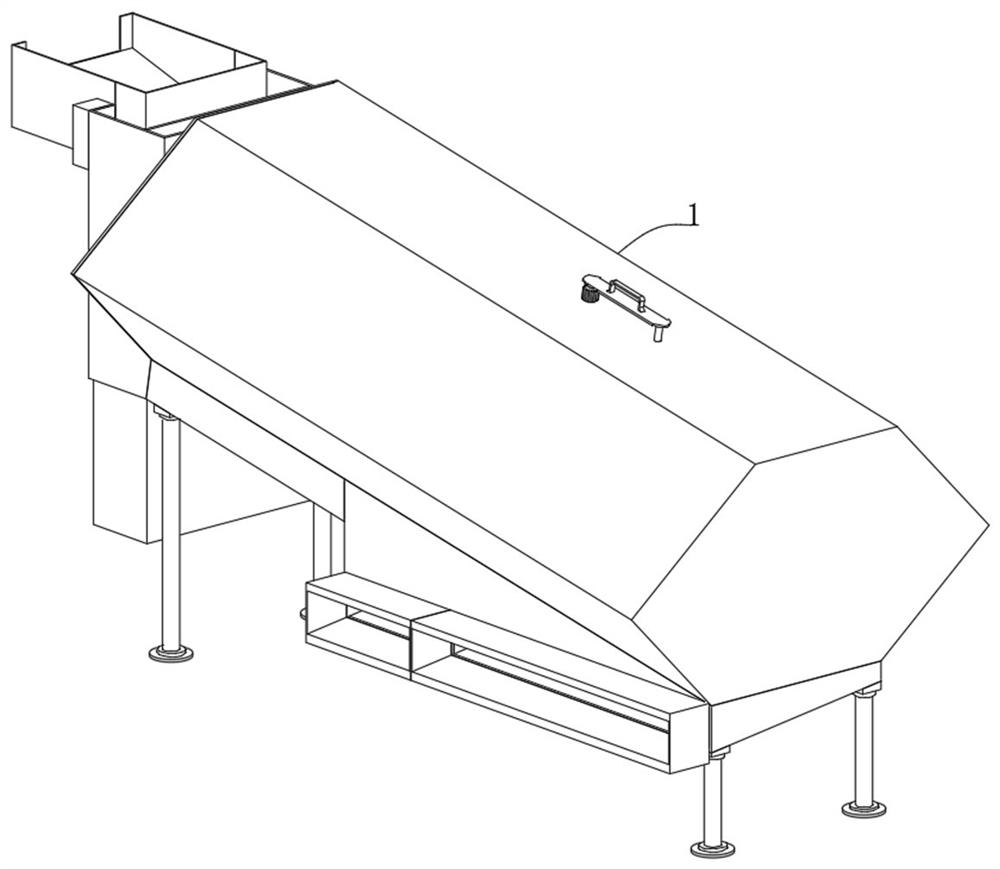

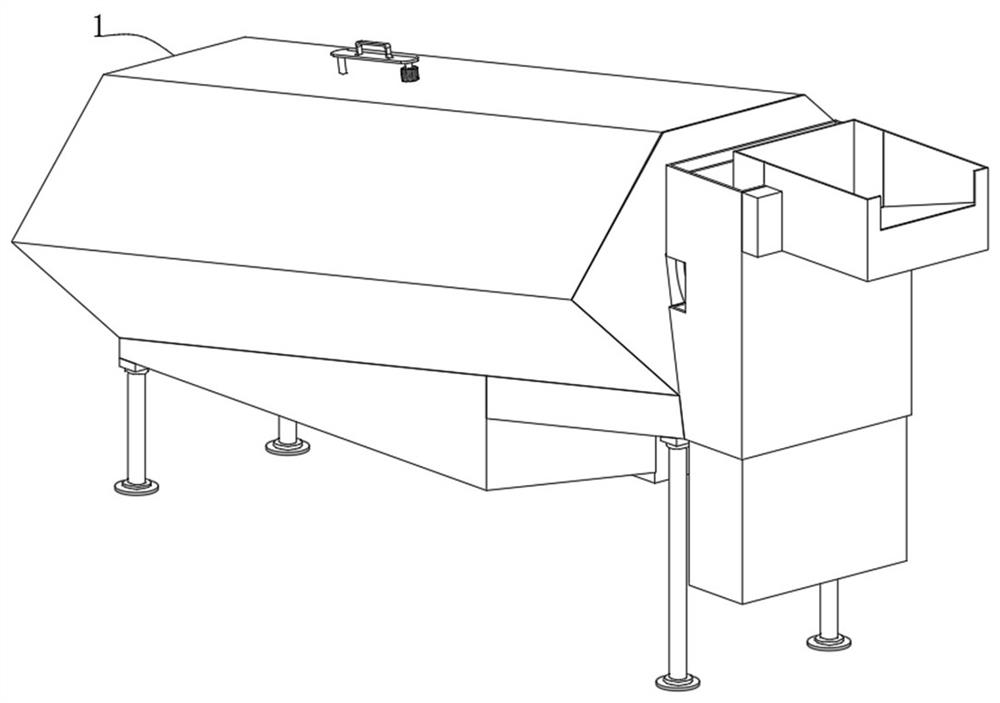

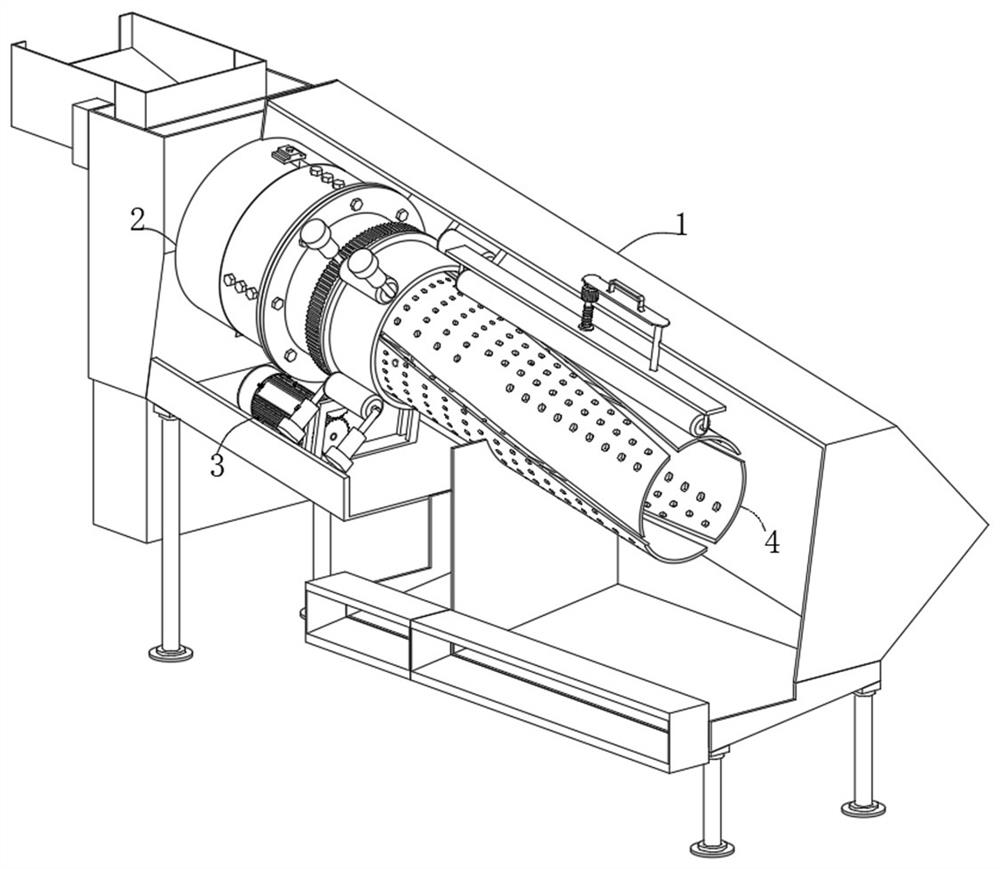

[0043] refer to Figure 1-Figure 13 : A concrete aggregate separation device, comprising:

[0044] The supporting mechanism 1, the supporting mechanism 1 includes a bottom frame 101 and a limiting part. The setting of the bottom frame 101 is used to provide an installation basis for setting other functional parts of the equipment, and at the same time facilitate the installation and setting of other functional parts of the equipment. The limiting part is set on the bottom On the frame 101, two support limit rollers 107 are fixedly connected to the inner surface wall on both sides of the bottom frame 101, and the support limit rollers 107 cooperate with the support limit ring 302, which can effectively fix and limit the position of the support frame 301;

[0045] The drive mechanism 3, the drive mechanism 3 includes a support frame 301 and drive components, the support frame 301 is set up to facilitate the installation of other functional components of the equipment, the drive ...

Embodiment 2

[0054] This embodiment 2 provides the working method of the concrete aggregate separation device, which is used to further explain the working process or principle of the concrete aggregate separation device provided in the above embodiment 1, which is specifically as follows:

[0055] A method for using a concrete aggregate separation device, comprising the following steps:

[0056] Step 1. Prepare for adjustment: Rotate the adjustment ring 110 so that the adjustment ring 110 can drive the supporting threaded rod 108 to adjust the position movement, so that the supporting threaded rod 108 can effectively adjust the use height of the pressing plate 113, and then enable the pressing plate 113 to drive the top roller 114 Squeeze and fit the screening plate 404, and then start the motor 306, so that the motor 306 drives the driving gear 307 to rotate, and then the rotating driving gear 307 drives the connecting gear 305 to rotate, and the rotating connecting gear 305 will drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com